Mineral wool cylinders - produced by SPECIAL TECHIZOLATION plant No. 1

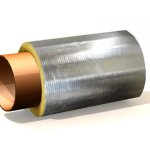

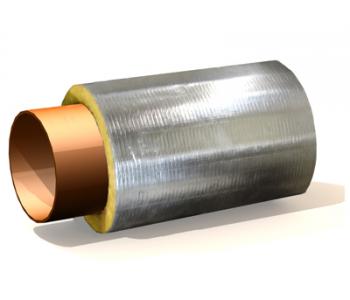

The search for a universal solution for the insulation of pipes intended for the transportation of heat carriers, gases and liquids led the specialists of the SPETSTEKHIZOLYATSIYA plant to the decision to use new materials and technologies that had already been successfully tested and proved their effectiveness. Thus, an insulating material was born, which is a layer of mineral wool with a dense structure. A thin sheet of foil aluminum was applied on top to improve the heat-reflecting characteristics and increase the resistance to Russian climatic conditions. The new insulator also coped well with temperature extremes typical for most regions of Russia, high humidity and exposure to ultraviolet rays. Resistance to mechanical damage and long service life have been demonstrated.

Modern heat-insulating material received a worthy assessment from practitioners, and mineral wool cylinders, lined with aluminum foil in a wide range of diameters and thicknesses, appeared on the market. Since during installation it is necessary to use various additional parts, for example, tees, the company has attended to the release of such products.

The safety of using the products of the SPETSTEKHIZOLYATSIYA plant is confirmed by quality certificates, certificates of conformity, as well as sanitary and epidemiological conclusions.

What are insulating cylinders

Heat insulating cylinders are designed for insulating sewer pipes, chimneys, water pipes

Heat-insulating cylinders are special structural elements used to insulate pipelines in heat supply systems and other highways. They have a cylindrical shape and are used as an outer shell of pipes to reduce heat losses. There are several types of cylindrical products, which are subject to the following requirements:

- low thermal conductivity;

- high level of sound insulation;

- resistance to climatic influences;

- chemical and frost resistance.

Basalt pipe cylinders are characterized by resistance to moisture and low susceptibility to harmful vapors.

Mineral wool cylinder production

The plant's assortment includes several types of products ER, TechnoNIKOL and ROCKWOOL, each of which is made on the basis of basalt wool obtained by weaving and compaction of stone fibers with the addition of a binder solution. The final product has hydrophobic properties and low thermal conductivity due to the presence of air between the basalt threads, which is a heat insulator. Bonding of aluminum foil enhances the natural qualities of basalt fibers and significantly increases the service life of mineral wool cylinders.

For ease of installation, an incision has been made along the axis of the cylinder, which facilitates and accelerates the seating of materials on pipes. Some products are characterized by an overlap with an adhesive layer applied, which allows the thermal insulation to be fixed and insulated to the surface.

The products of the SPETSTEKHIZOLYATSIYA plant are suitable for use in closed rooms and in open spaces, for process pipelines and pipes of utility / engineering systems, operated in conditions with high humidity and low temperatures.

Range of products

Among the products of the plant there are mineral wool cylinders, lined with aluminum foil, products without a protective coating, shaped parts - tees with and without foil, as well as shells with a protective coating in the form of a galvanized casing. The range of products covers the needs of the most popular sizes - in diameter (18 - 324 mm) and thickness of the mineral wool layer (20 - 200 mm).

Depending on the availability and type of protection, the shells can be used for outdoor installation - with a metal casing, or indoors - lined with aluminum foil and unveiled.

When choosing a particular type of product, the specialists of the plant are ready to provide free advice on the types of products, and if there is a pipeline plan indicating the dimensions and connection points of the fittings, prepare a complete set of thermal insulation materials with the required number of additional segments.

Important technical characteristics and advantages of mineral wool cylinders

Shells produced from mineral wool and coated with a protective coating exhibit a number of outstanding parameters highly appreciated by installers and customers:

- excellent thermal insulation properties;

- resistance to atmospheric moisture and temperature extremes;

- ability to work in a wide temperature range - -180˚С - + 450˚C.

- hydrophobicity, allowing installation in conditions with high humidity;

- resistance to chemicals - oils, petroleum derivatives, alkalis, acids;

- the ability to withstand serious mechanical loads, including breaking;

- high fire safety and non-flammability;

- non-toxicity and safety for indoor installation;

- high level of sound insulation;

- durability;

- convenience in storage;

- ease of installation;

- versatility at the place of application - utilities, production shops, including at enterprises producing food products, gas, oil and other transport systems.

The purchase and installation of foil-clad mineral wool cylinders allows you to obtain a significant economic effect and gain priority in the market for goods and services.

5 reasons to buy the products of the SPECIAL TECHNICAL INSULATION plant

All the most important criteria for the selection of heat-insulating materials, which are important for the buyer, installer and user of piping systems, are inherent both for the SPECIAL TECHIZOLATION plant itself and for its products:

- high quality production and control of product parameters at every stage;

- a wide range of products, and therefore the ability to select products that are optimal in terms of their characteristics;

- free consulting and the possibility of calculating the project for the thermal insulation of the pipeline;

- excellent service, implying maximum satisfaction of the customer's needs both in terms of the quantity and quality of products, and in terms of information support;

- the possibility of delivery across the territory of Russia;

- adequate prices for mineral wool cylinders, allowing to reduce overhead and increase the profitability of the enterprise.

If you are still trying to calculate the cost of thermal insulation of pipes, then just trust the company's specialists who will choose the best solution, calculate the project, and organize the delivery of materials directly to the installation site.

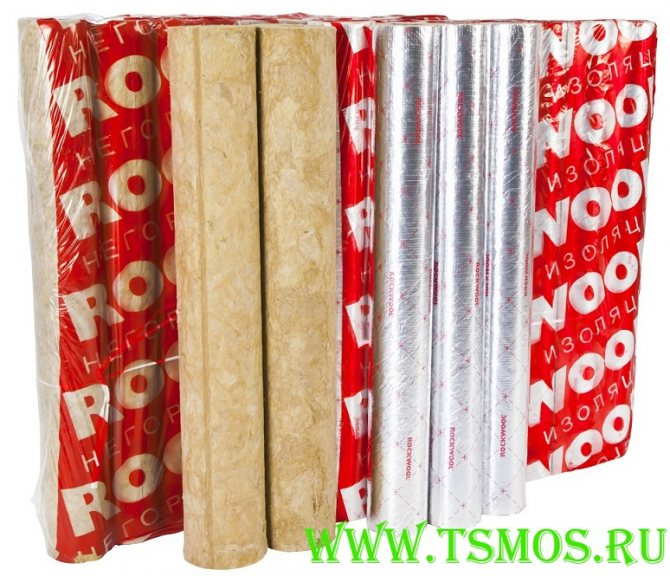

Rockwool Cylinders

Rockwool 100 wound cylinders are the best solution for insulating main and industrial pipelines with a coolant temperature of up to + 650 ° C. It is important to note that among the competitive materials that are made by the cut-out method, Rockwool wound cylinders occupy a leading place. This is due to the best thermal conductivity, high quality raw materials and modern production methods.

Rockwool 100 wound cylinders are manufactured in the city of Zheleznodorozhny, Moscow region, and in the city of Troitsk, Chelyabinsk region. They are made with internal pipe diameters from 18 to 273 mm.The wall thickness of the mineral wool cylinder can be 20, 25, 30, 40, 50, 60, 70, 80 and 100 mm. If the project requires insulation of a larger diameter of the pipeline, then in the line of materials there are Rockwool ProRox cylinders made in Holland, which are promptly produced and delivered to our country. Also, it bobs and non-standard thicknesses that are common in oil and gas facilities.

Heat-insulating cylinders Rockwool can be produced with aluminum foil coating. Reinforced aluminum foil bears the ROCKWOOL logo. Due to this, it is easy to identify the manufacturer and not to be confused with similar materials. The products are delivered in several pieces of dense plastic packaging.

Application area

Thermal insulation of pipelines of engineering networks, hot and cold water supply, main and internal heating. Insulation of industrial pipelines: steam pipelines, pipelines with a product of the petrochemical industry.

Engineering systems

The requirements for the thermal insulation coating are as follows: ensuring a safe temperature on the insulation surface (40 C) and reducing the level of heat loss to the standard SNIP 41-03-2003.

Rockwool cylinders, possessing low thermal conductivity coefficients at different temperatures of the coolant, satisfy the necessary requirements. In the case of cold water pipelines, the insulation prevents condensation from forming on the pipe surface. This aluminum foil-coated pipe insulation solves this problem, as the foil acts as a vapor barrier.

In addition to high thermal performance, the cylinders are easy to install, since they do not require the use of glue. The formed pipe sections can be easily put on the already installed pipelines, after which the joints are glued with aluminum tape, giving the structure a finishing decorative look. It is important that the cylinders are a fire-safe product, having a fire hazard class KM0 (KM1) in accordance with the new technical regulations on fire safety requirements. This characteristic is especially relevant in connection with the tightening of the requirement for fire safety in construction.

Industrial insulation

Low coefficients of thermal conductivity are especially relevant in industry, since the temperatures of the coolant in pipelines reach several hundred degrees. Cylinders, with an application temperature of up to 650 ° C and low thermal conductivity, solve the problem of increasing the energy efficiency of such pipelines. In the petrochemical and energy industries, the issue of fire safety of the material is especially important, therefore, the insulating material must have a fire safety class of at least KM0.

Under the influence of high temperatures and mechanical shock effects, most thermal insulation materials quickly deteriorate, sliding down the pipeline. The cylinders easily take these loads, remaining a form-stable material for many years of operation.

Video: Rockwool wound cylinders

Download price list and mini-brochure about Rockwool products:

It might be interesting:

| |

| |

| |

| |

|

LLC GK "TEPLOSILA" - together with you since 2005!

Mineral wool cylinders - how to buy and get?

After the main parameters of the order have been determined - technical characteristics, dimensions and number of products of a certain article, the order can be left using a special form, sent by mail or by telephone.After a while, the manager will contact you to clarify the parameters of the order and inform the cost by sending you a payment order to the address.

Delivery of mineral wool cylinders, lined with foil and without it, is carried out throughout the territory of the Russian Federation due to the presence of a wide network of branches and representative offices in various regions of the country.

Applications

Insulation of sewer pipes with basalt foil cylinders

According to current standards, cylindrical protection is allowed to be used:

- in private and collective housing construction;

- in heating mains of multi-storey buildings and other urban facilities;

- in piping systems installed at production sites;

- on main lines through which heat carriers and other easily freezing liquids are pumped.

Most of the samples of cylindrical protective products are suitable for insulating almost all of the designated structures. At the same time, cylinders based on mineral (basalt) wool and their analogues are especially versatile. They are allowed to insulate the following household and industrial facilities:

- open and underground heating routes;

- piping systems through which liquid is pumped, heated to very high temperatures (up to 600 ° C);

- water and sewerage lines to protect them from freezing.

Particularly popular are Rockwool cylinders lined with aluminum foil, as well as polyurethane foam shells. With their help, most of the pipe routes that are part of heating systems and individual water pipelines are insulated.

Delivery and labeling

Products are packed in branded corrugated cardboard boxes that can be stored outdoors under a canopy. The label indicates the number and size of products. We carry out prompt delivery by various types of transport to the regions of Russia, the CIS countries and abroad. During transportation, boxes are placed vertically no more than 2 rows, horizontal arrangement is possible in the absence of load. Each shipping location has corporate symbols and a label indicating the nomenclature. Boxes are transported by covered transport, stored in covered warehouses or under a shed. There are no temperature requirements.

specializes in the production of thermal insulation, takes into account the needs of customers and sells products at prices from the manufacturer. Our specialists can perform a heat engineering calculation and produce products of non-standard shapes.

Mineral wool - why this material?

It is also worth adding that the numerous advantages of insulating cylinders are largely determined by the excellent characteristics of the mineral wool itself - the key material used for such elements. The advantages of mineral wool can be attributed to the fact that it:

- does not burn (it can melt, but only at really critical temperatures - about 1000 degrees);

- retains a large amount of air in its fibers, due to which the thermal conductivity of the material is minimal;

- not harmful to our health;

- not afraid of mold, fungi, pests;

- environmentally friendly.

Note! Many, trying to somehow save money, are interested in whether it is possible not to insulate the pipes at all. We will answer: if the winters in your region are cold, then, unfortunately, you cannot do without insulation. Otherwise, the liquid moving through the pipes will freeze and turn into ice, and the temperature conditions in the heated room will be far from normal.

For the manufacture of mineral wool, basalt rocks are used, as well as special binding components. For this reason, the shell is often called “basalt heat-insulating cylinders”. Although, in principle, we are talking about the same material.

In addition, we note that the mineral wool for cylinders is significantly different from the traditional building mineral wool.For the same reason, building modifications should never be used to insulate pipelines. The fact is that such a material does not have (or does, but in insufficient quantities) one extremely important property - namely, hydrophobicity. at the same time, mineral wool cylinders are considered a new generation of building materials, significantly superior in many of their indicators to the once popular liquid thermos paints and glass wool. A simple and affordable solution that is suitable not only for industrial enterprises, but also for ordinary citizens.

Varieties and appearance of products

Heat-insulating cylinders for pipelines have a diameter inside the same as the diameter of the pipe for the insulation of which they are used. These can be one-piece and composite products of several types.

- Single cylinder with a cut along the length to simplify installation work when insulating pipes of small diameters.

- Two-piece of 2 half-cylinders with a longitudinal cut, used for insulating pipes with medium diameters.

- Lamellar (multi-piece) consists of several segments assembled on a pipe into a single cylinder. It is used for insulating pipes with a large diameter.

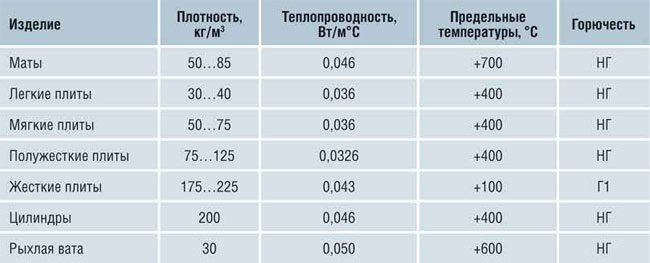

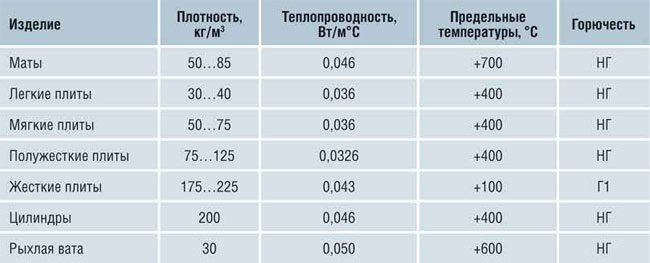

According to GOST 31913-2011, wool made of inorganic materials can be:

- Glass made from molten glass;

- Stone, made from molten rock, sedimentary and volcanic rocks;

- Slag from metallurgical or industrial slag.

Inorganic wool can have a spatial, corrugated, vertically or horizontally layered structure, which determines its quality characteristics. The density of the mineral wool according to the manufacturer's specifications varies:

- For 80 brands within 65-95 kg / m3;

- For 100 grades within 95-125 kg / m3;

- For 120 grades in the range of 125-175 kg / m3.

Thermal insulating cylinders for pipes may or may not have an outer protective layer of aluminum foil or a galvanized sheath. In addition, these products are used for thermal insulation of a system of 2 pipes, which are covered with one cylinder, which makes it possible to simplify and reduce the cost of installation work.

Dimensions (edit)

The dimensions of the cylinders mean their diameter. The products are available in various sizes. The minimum diameter of a cylindrical insulation made of foamed polyethylene is 18 mm, while the maximum reaches 160 mm. The sizes of mineral wool heaters also start from 18 mm, but the range of indicators is much wider - the maximum size of the diametrical circle is 1020 mm.

Important! If necessary, the manufacturer can create products for the dimensions required by the customer.

Brief description of mineral wool cylinders

Thermal insulating cylinders got their name because of their appearance: in principle, each such element is really a cylinder (pipe), which must be put on those sections of the pipes that need to be insulated. The technology of mounting such cylinders on pipelines is provided by manufacturers: each element has one cut and one cut along the length, as a result of which, in fact, it will be more correct to call them half-cylinders. By the way, these insulating elements have another name - shells.

How to install mineral wool cylinders with your own hands: important points of the process

We have already said that mineral wool cylinders are extremely convenient to install, even in those cases when it comes to difficult sections of the pipeline (for example, if the heating main was laid underground). The installation procedure takes a minimum of time; this is exactly what the material described in the article compares favorably with other heat insulators. The insulating shell for pipes is obliged to such assembly conveniences by two longitudinal lines (notch and cut) on the product axes, as well as special "locks".All of these elements allow the cylinders to be snapped onto the pipeline, and it is quite obvious that no specialized equipment or special skills are required to carry out this operation.

Although there are several important recommendations that everyone who plans to install insulating cylinders with their own hands must know about. Let's get acquainted with them.

- The absence of "humps" indicates that the size of the shell was correctly selected.

- In the case of mounting the cylinders on a vertical type structure, it is necessary to install special reinforcing rings with a step of 4 meters. This will prevent the insulation from slipping.

- When installing, each new cylinder should fit as tightly as possible to the adjacent one.

- If a non-laminated cylinder is used, it must be additionally reinforced with a strong wire.

Foil heat-insulating cylinder - manufacturing and sale

Acquaintance with the technological process of production of the mineral wool itself and the final products from it allows you to understand how heat-insulating foil cylinders can be useful. Already the raw material itself lays down certain qualities in the future product. So, for example, the fibers obtained from basalt have high strength and fire safety: the melting of stone threads is possible only when the combustion temperature reaches 1000ᵒС.

So that the cylinders can cope with their main function - to isolate pipes from the negative effects of the environment - temperature drops, humidity, ultraviolet radiation, basalt threads are wound and create a dense shell. To keep the fibers in a static state, a binder is used that does not detract from the natural qualities of basalt. Coiling technology helps to achieve uniform thermal conductivity characteristics along the entire circumference and length of the insulating shell.

Foiling, or lamination, is a way to enhance the qualities already inherent and give the final product greater mechanical strength, and hence durability. By the way, the application of aluminum foil is carried out in such a way that an overlap or valve is formed at the junction of the ends of the cylinder cut along the axis. An adhesive is applied to one side of the valve, which is protected by a foil. Such a valve turns out to be in demand when installing shells and performing joint insulation: the film is removed and the foil is simply glued to the opposite side, thereby hiding the seam.

Laminated shells can be reinforced with fiberglass to increase the mechanical strength and durability of products.

Benefits of mineral wool products

Inorganic wool does not support combustion, and according to the flammability class it belongs to the NG category. Thanks to this feature, pipes for transporting liquid and gaseous substances with an internal temperature in wide positive and negative ranges, both in open areas and inside structures and buildings, are insulated with inorganic wool.

Manufacturers offer mineral wool heat-insulating cylinders of various lengths and thicknesses. We also offer products for 2 or more pipe systems, in which pipes can have different diameters from each other.

Mineral wool products are environmentally friendly and resistant to aggressive substances. In addition to all of the above advantages, mineral wool heat-insulating cylinders have a number of characteristics that allow:

- perform installation in a short time;

- provide a high degree of sound insulation;

- arrange reliable connections at the docking points;

- use in a wide temperature range;

- reliably protect the environment.

Insulation production

The most popular is the mineral wool cylinder, the price of which is available to all buyers.For the manufacture of this insulation, rocks and carbonate rocks are used, as well as additives of organic origin. Thanks to the winding technologies, in the production of this material, the same coefficient of thermal conductivity is ensured over the entire surface of the pipes.

Mineral wool heaters go on sale with or without coating. The coating can be a fiberglass layer, a protective galvanized casing or an aluminum foil layer. There is also a coating in the form of a fiberglass mesh with a layer of foil applied.

Quality control, warranty and service life

Quality control of the product must comply with GOST 4640-2011 and TU of the plant that produces cylinders from mineral wool. In addition, according to quality control, before the product is released from the factory, it must lie in the warehouse for 24 hours. The manufacturer is obliged to produce pipe insulation with appropriate mechanical properties, dimensions and without distortion from the main appearance of the product. In the warehouse, the product is stored for no more than 6 months, after which, if it is not sold, it is disposed of. At the same time, the product that has passed the installation has a service life of up to 50 years.