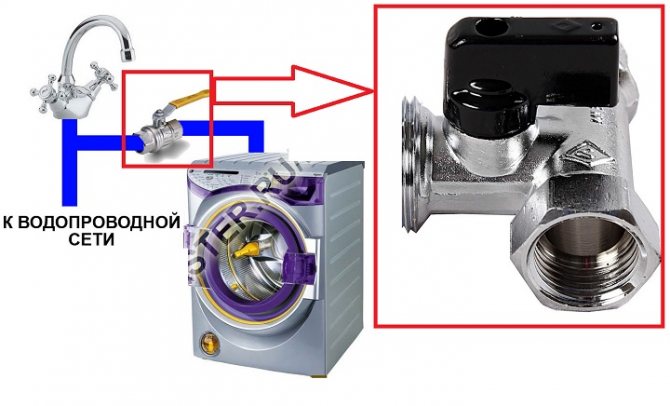

Why do you need a faucet for a washing machine

The need to install a tap when connecting the washing machine and disconnecting it from the water line during the idle period is justified in the manufacturer's instructions for use, there are two main reasons:

- The flexible supply hose is not designed to maintain a constant pressure in the system; if it rises or abruptly surges, the sheath may break.

- The check (shut-off) valve in the water supply system has a design in the form of a spring and a rubber disc; it is designed for temporary operation when the chamber with the drum is filled with water. The constant pressure of the water column leads to an extension of the spring and, accordingly, to a loose fit of the shut-off diaphragm valve. Also, with constant squeezing, the rubber gasket itself may burst - the listed factors lead to disruption of the operation of household appliances and leaks.

In the water supply system, the tap must operate in an on-off mode, which does not require adjustment of the water flow, therefore, simple inexpensive and reliable designs are used with long time intervals for maintenance, repair with replacement of worn-out units. The shape of the body during installation is selected from the point of view of the most convenient connection option and access to the handle, which, in turn, is designed as a long asymmetric lever or a butterfly handle.

Bugatti brand design

Dual connection

There are models of automatic washing machines in which there is the possibility of double connection to the water supply: both to cold and hot water.

Such opportunities are present in American and Japanese manufacturers of washing machines.

This was created in order to save on electricity, because in machines without a double connection, cold water heating is used. As practice has shown, in Russia such machines do not often cope with their work.

In general, washing machines are quite demanding on the quality of hot water supplied to them. Usually, in a centralized heating system, water is not considered as clean as we would like, therefore, pollution and clogging of filters, various kinds of breakdowns, and so on occur. The wash performance may not be good enough.

As a rule, in conditions of individual water supply, water is much cleaner.

But we still recommend that you conduct an analysis and assess the condition of the water before buying and installing a washing machine.

The water may not be in good condition, which means that the cleaning system should be improved. If this is not done, your washing machine will become very vulnerable to possible breakdowns.

The end valve can only be connected to an existing water supply.

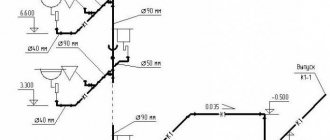

Tie-in scheme into a centralized water supply system

If there is a collector well in the area where your house or plot is located, then the tie-in is carried out (if allowed) in this well. If it is located far away, then access to the pipe is carried out through an additional well.

- in the place indicated by the project, they are digging a square pit measuring 1.51.5 meters;

- from the pit, in the direction of the house, they dig a trench for future allotment;

- upon completion of all work on the tie-in point, an additional well with a cover is erected to access the connection point.

Connection to a centralized pipe, which is under pressure, is carried out in two stages:

- Fitting a branch flange with shut-off valve.

- Reaming the pipe body.

You can cut into a plastic water pipe with or without welding. Connection to steel communications is usually carried out using a welded flange.

Note! The general rule of tapping in a branch is that the diameter of the cut-in communication is always less than the diameter of the central pipe.

Prepare for the process

The owner of the automatic machine needs to know the peculiarity of the procedure for installing the unit to the water supply.

After all, a breakdown of a special crane may occur, which in the future will need to be replaced, or if the machine needs to be rearranged to another place in the house. Even a beginner in this matter can cope with the task quite well if he remembers the list of important points.

We invite you to familiarize yourself with the Cotton function in the washing machine

When installing a washing machine, it is possible to use shut-off valves of a fairly simple design.

The installation of such taps is carried out in a conspicuous place so that the owners can shut off the water entering the washing machine at any time out of control.

The machine automatically performs various actions, heats the water, having previously taken it from the system, at this time all sorts of breakdowns can occur, which can be prevented only if the tap is in a visible place, and then it becomes possible to turn the valve and stop the water supply.

In most cases of car breakdowns, it is necessary to shut off the water, and if this is not done, then there is the likelihood of flooding the apartment (house) and neighbors.

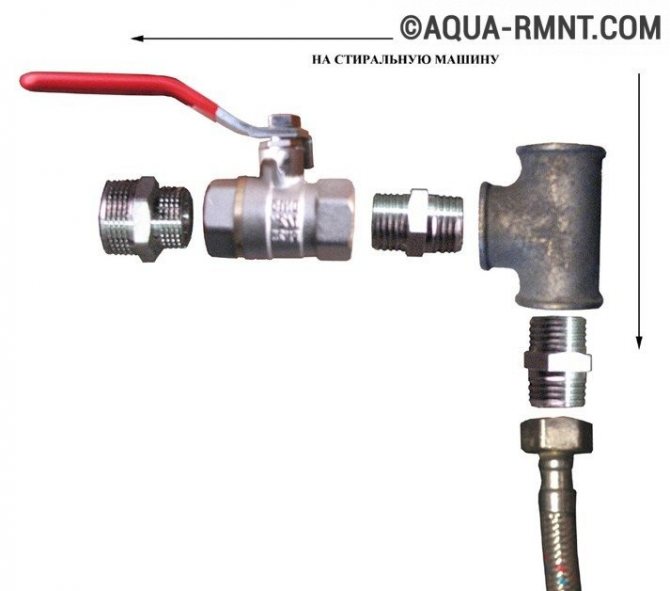

When connecting your washing machine, you can use shut-off valves, the variety of which is divided into two categories:

- They are cut into the existing water supply system, which goes to other objects (mixer, boiler, etc.);

- End tapsThey are placed on the branch of the water supply system, specially made for automatic machines.

It would be better for a washing machine if it received water from the plumbing that runs throughout the house, of exactly the same cross-section.

It is advisable to install a filter in the system - it will purify the water that will enter the machine.

https://www.youtube.com/watch?v=KCsq1YbxZ-A

The filter is a mesh that is very easy to install. Remember to clean it periodically.

We recommend that you turn off the water supply to the machine after washing, and turn it on only before starting it.

Or you can install a whole system of filters. But this is subject to the availability of material opportunities.

Which hose is better?

It may be that the manufacturer provides a special hose for connecting to the water supply, and if there is one, then it is better to install it. The length of the provided hose may not be enough, so you should not immediately connect it from two parts, because in this case it will soon be broken.

The best option is to buy a new, longer hose in a special store from the manufacturer of your machine. It is better to buy a hose in a company store, because cheap analogs in ordinary stores, as a rule, break down very quickly.

Stage # 2 - preparing for installation

The purchased machine is delivered to the apartment in a packed form. All rotating parts are secured with fasteners (bolts, bars, brackets) that protect the device from accidental damage during transportation.

Before starting the installation, it is important to remove all fasteners (bolts, brackets, clamps) that protect the parts of the machine during transportation

The brought washing machine should be freed from the box, and then start removing the fixing parts:

- The brackets must be removed from the rear wall of the unit., which are set for the rigidity required for the transport of household appliances. Such elements also support flexible parts of the structure, namely the hose and the electric cord.

- Following this, it is necessary to remove the barsplaced between the tank and the body of the device. To do this, just tilt the washer slightly forward.

- The bolts should also be removed.which are installed on the front of the machine to fix the drum. It is better to immediately insert plastic plugs into the holes from the removed elements (they are usually supplied with the model).

Released fasteners must be carefully packed and stored: they may be needed when contacting service.

Image gallery

Photo from

Washing machines are transported with the obligatory installation of fastening bolts that fix the position of the internal moving parts. Remove them before connecting.

There is a wrench for unscrewing the bolts. With its help, you first need only to loosen the fasteners

While holding the bolt with a wrench, you need to carefully remove it along with the plastic insert. Then you need to close the hole with the plastic plug supplied with the model.

The bolts unscrewed from the washing machine together with plastic inserts and a wrench must be stored. They can still come in handy if home equipment has to be transported.

Installation points for fixing blots

Loosen the bolts with the supplied wrench

Removing the bolt together with the plastic insert

Collecting the shipping bolts for storage

We recommend: Correct washing of bed linen

Constructive execution

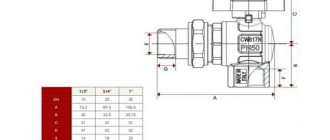

The ball valve has a simple design, a high degree of waterproofing, small dimensions and easy to use, the main structural elements of a standard product are:

- Housing. A typical collapsible design is made of nickel-plated or chrome-plated brass, an external thread is applied to the inlet and outlet pipes for connecting to the pipeline and plumbing fixtures, electrical engineering.

- Ball. It is made of brushed and polished brass, chrome-plated on top, a rectangular recess is made inside its body on top, into which the stem is inserted.

- Stock. It is a brass rod with sealing rubber rings installed on the body, a crane is attached to one of its ends. There is a hole at the top for screwing in a fixing screw or a thread is applied to the pulley for attaching the handle to the nut. The opposite side of the stem has a rectangular cross-section and is intended to be inserted into the ball valve body.

- Landing and sealing rings. Seat rings, located on either side of the ball at the inlet and outlet of the bore, provide a seal by preventing water from entering the outlet when closed. A rubber ring, put on one of the parts of the body, prevents it from leaking when connected to another part.

- A pen. The swivel handle is made in the shape of a butterfly or an elongated lever, attached to the stem with a screw or self-locking nut made of nickel-plated steel. It is made of aluminum, nickel-plated steel, coated with polymers in a liquid plasticizer (plastisol).

We suggest that you familiarize yourself with Is it possible to replace the shower tray

Characteristics and materials of a typical valve

Installation methods

So, in addition to the metal pipeline, which has become classic long ago, the following types of materials are currently used:

- Metal-plastic;

- Low-pressure polyethylene;

- Polypropylene;

- PVC.

Below we will take a closer look at the features of installing valves with our own hands for each type of these pipelines.

Reinforced-plastic pipeline

So, let's look at how to connect a metal-plastic pipe to a crane.First of all, it should be said that metal collet valves are used for metal-plastic. They are installed very simply, and this does not require special tools or special skills.

The fastening element of such devices consists of the following elements:

- Nut;

- Collet ring;

- Fitting (located on the device body).

The instructions for doing this work are as follows:

- First of all, you need to cut the pipe evenly so that the cut is perpendicular to its axis.

- The junction of the parts must be thoroughly cleaned.

- Then the nut and collet ring are put on.

- After that, the tube is put on the fitting.

- Next, a collet ring is pushed onto the junction and the nut is tightened. For tightness, fum tape should be wound on the thread.

- After that, in the same way, the shut-off valves are connected to the pipeline on the other side.

I must say that working with metal-plastic is generally very simple. For example, if you need a tap into a water pipe that has already been installed, you can simply cut it and install the shut-off valves as described above.

The valve for polyethylene pipes is also made of polyethylene, and even the locking mechanism is made of plastic, however, this does not affect the durability of the valves. As for the installation method, it can be carried out in three ways:

| Tsangov | This method of installation resembles a tie-in of shut-off valves into a metal-plastic pipeline, however, the fastening element itself is made somewhat differently. Therefore, before connecting the faucet with a plastic pipe made of polyethylene, it is necessary not only to cut the last one exactly, but also to chamfer a few millimeters. In addition, in addition to the nut and collet ring, a retaining and O-ring is put on the pipe before installation. In addition, the device itself does not have a fitting. |

| Foltsev | It is also a fairly simple installation method - the connection of the plastic pipe with the tap is carried out using a bolt method through the holes in the folds. It should be noted that this installation method is not used in household pipelines. |

| Welded | Welded mounting is also quite rarely used in domestic pipelines. For its implementation, a special welding machine is required. Moreover, welding can be carried out in two ways: |

- By melting the ends of the parts to be joined, which are subsequently pressed against each other with force.

- Coupling method - an electric coupling is applied to both parts, to which electricity is connected and heats the parts to be connected.

Note! There are valves with a combined installation method, which, as a rule, additionally serve as adapters between pipelines made of different materials.

Polypropylene

Faucets for plastic pipes made of polypropylene are made in the form of a sleeve. Their installation is carried out by a welded method, respectively, for these purposes you will need a special welding machine, which is also called a soldering iron.

Below we will take a closer look at how to put a faucet on a plastic polypropylene pipe:

- First of all, you need to install nozzles of a suitable diameter on the soldering iron.

- Then you need to turn on the soldering iron and wait until it warms up to operating temperature... This will be indicated by a green indicator.

- While the welding machine is warming up, you need to clean the tube (if it is reinforced)... For these purposes, you should use a special tool - stripping, which is put on the tip of the tube, and then rotated several times.

- After that, you need to insert the parts to be connected into the nozzle and wait a certain time until their surfaces warm up and become soft. The times for each diameter of the parts are indicated in the table that comes with each welding machine.

- After the time indicated in the table, you need to remove the parts from the nozzles and connect... In this position, they need to be fixed until the plastic cools down.

- Further, in the same way, the shut-off valves are connected on the other side.

Advice! Before you cut the faucet into a plastic pipe made of polypropylene, you should practice on scraps of pipes and cheap fittings so as not to spoil the valve, since the price of this product is quite high.

Here, perhaps, are all the main points of how to connect a faucet to a plastic polypropylene pipe.

Often, PVC pipes are used for water supply systems, for which a separate type of stop valves is also used. The connection is carried out by a threaded method, however, for this, the lugs that are included with the device must be glued to the pipes.

This installation method is quite reliable, since the adhesive melts the surfaces to be joined, and, in fact, they are welded to each other.

Types of taps for washing machines

Manufacturing material. Plumbing fixtures are often made of metals: brass, stainless steel, silumin, brass products are considered the most expensive and high-quality ones. The cheapest shut-off valves are made of silumin - an aluminum alloy, products have low strength and light weight, unlike expensive metals, they have low plasticity and crack under load.

On the market, you can find low-cost polymer shut-off valves, plastic taps are conveniently mounted in a polypropylene pipeline by soldering - this saves on plastic-to-metal adapters and in cost compared to using metal products.

The principle of the locking mechanism. There are two main types of shut-off valves: screw and ball, in the first there is a gradual multi-turn shut-off of the flow due to the rotation of the screw shut-off valve, which is irrational for valves, the only purpose of which is to supply and cut off the water flow.

Polymer valves

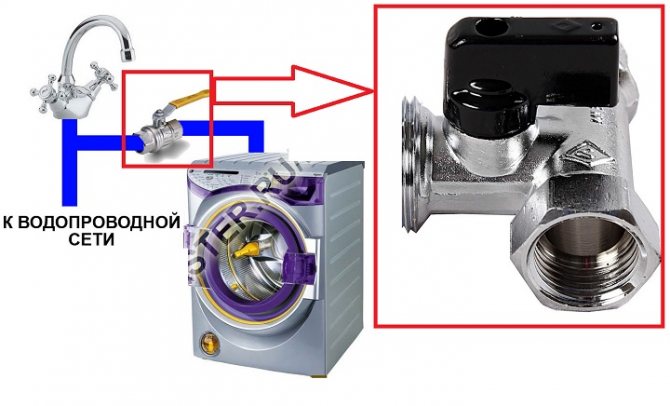

Housing design. Depending on the location of the pipeline and ease of access, the following types of taps are installed in the water supply system:

- A straight or straight-through valve for a washing machine has an inlet and outlet branch pipes located in one line, mounted in a pipeline that has a separate outlet for connecting equipment.

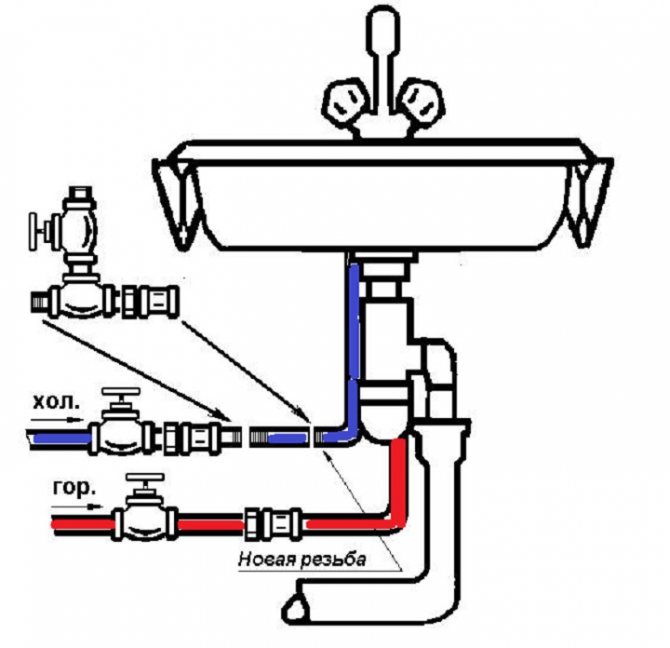

- Tee crane. In this type of construction, the water flow is straight inside the housing, and there is a branch in the side wall for connection to the machine. The tee for connecting the washing machine to the water supply is used in water supply systems with previously connected plumbing equipment. Typically, a three-way valve is installed under sinks in a kitchen or bathroom, connecting a flexible hose from the sink and the washer to the throughlet and outlet pipes, respectively, and the faucet body to the water pipe.

- Angular. Often, the washing machine is connected to a water outlet built into the wall, while it is much more convenient and rational so that the inlet of the flexible water supply line approaches it at an angle of 90 degrees. To do this, screw an angle faucet for a washing machine of the corresponding diameter into it and connect a hose to it, lowered down the wall.

We offer you to familiarize yourself with the Design of a bathroom in a wooden house

Types of valve bodies: straight-through, tees, angle

Varieties of PP ball valves

Cranes differ in diameter and purpose.

They are found directly for hot water supply, which are more resistant to high-temperature flow, there are valves for cold water supply, made, as a rule, from cheaper grades of polypropylene.

By design, they are divided into detachable and collapsible types.

- Detachable are designed to disconnect the valve from the pipeline, in cases where it may be required.

- Collapsible. Connection method using a union nut ("American"). Used to connect to manifolds, tanks, sensors, steel pipelines. Staple connectors are available both on one side and on both sides, which makes the use of PPR ball valves more flexible. Collapsible cranes are of two types: straight, angle. The purpose of the straight lines is a serial connection with another section of the pipe without changing the direction of the structure. In the event of a change in the direction of the pipe, for example, when connecting to a manifold, an angle valve is installed.

We recommend that you familiarize yourself with: How to make the right brick chimney with your own hands?

There are also one-piece structures that differ only in the method of installation. Designed for connection with sections of a polypropylene pipe or PP collector. The paper clip uses welding, which complicates the further maintenance of the system. To replace the structure, the crane will have to be cut with a pipe section.

Differences from brass taps

Polypropylene ball valves cannot serve as control valves. An analogue with the ability to adjust the flow of the working medium is a brass valve.

Brass taps are serviced structures. It is much easier to disassemble and repair, so that, in case of failure, it will be possible to replace the damaged part without replacing the product.

In structures where the pressure exceeds 20 MPa, or temperatures below -10 ° C or above 95 ° C, it is recommended to use brass products. They are more pressure resistant and have a wider operating temperature range.

Note! The disadvantage is the cost, which exceeds the price of PPR products by 2 - 3 times, therefore, it is economically expedient to use brass taps where the disadvantages of polypropylene are most significantly manifested.

Criterias of choice

1. Ball valves are best suited for quickly stopping and turning on the water supply, in which a ball-shaped shut-off mechanism with a through hole instantly blocks the water flow when the handle is turned 90 degrees.

2. For aesthetics and to prevent unplanned rotation of the handle, use products with a compact butterfly swing arm. In places where access is difficult and it is impossible to remedy the situation, it is more rational to use a model with an asymmetrical long lever, which is easier and easier to turn.

3. The best material for manufacturing valves is brass, which is not subject to corrosion and has a service life of tens of years; household valves of this type have a chrome coating, which gives them a beautiful aesthetic appearance. Brass taps are installed in a steel metal or polymer (polypropylene PP) pipeline, into the latter an adapter from plastic to metal is soldered.

4. The choice of the design of the faucet body depends on the connection option - if it is installed in a gap or the pipeline to which the sinks, mixer or its ebb, shower hose are connected, use a triple design. With a water outlet coming out of the wall, the best option is an angular housing, the direct through-passage modification is not used too often and is connected to pipelines or water sockets located at the bottom of the floor.

Tap with inlet hose connected to a water outlet

5. When buying, sometimes you should pay attention to the position of the handle, at which the tap is open or closed, for example, it is more convenient for a valve with a long lever close to the wall covering to close closely parallel to the wall, and open perpendicular to its plane, protruding outward - this will prevent involuntary turning and unwanted opening of the channel for water intake.

6.When choosing a suitable model in a hardware store or on the market, you should pay attention to the manufacturer (for branded fittings, the company logo is applied to the body). The sanitary fittings of the following Russian and European brands are of high quality and have proven themselves in the domestic market: Bosch, Bugatti, Elsen, Grohe, Itap, Valtec.

How to install a faucet

There are several ways to connect the washing machine to the cold water supply line, depending on which various types of plumbing fixtures are purchased, the following accessories and tools are used during the operation:

- Adjustable wrench, screwdriver.

- The inlet polymer hose supplied with the machine or a product purchased from a commercial network with a 10% margin in length for long distances from the water outlet to electrical equipment.

- Ball valve of angular, direct-flow or tee-type body design.

- Sealing materials: flax fiber, plumbing thread, Fum tape.