- 1 The choice of material for the upcoming work

- 2 Structural elements of equipment

- 3 Reasonable choice of design

- 4 Design and installation rules

- 5 The main nuances of work and use

Furnaces are traditional designs for complete, uniform and high-quality heating of buildings. However, they are often installed for such houses, which are large in size and several rooms located far enough from each other. In this case, one stove will not be able to provide uniform heating of each room due to insufficient power. In this situation, the most optimal solution is a coil, which is also called a heat exchanger. It is connected to a heating device, after which it is carried out through all the rooms of the building itself, as a result, it provides optimal and uniform heating.

The choice of material for the upcoming work

The coil is usually created using a pipe that has a suitable length and diameter... During the selection, it should be borne in mind that all the parameters of this element will directly affect the quality of heating in the house, as well as its efficiency. Therefore, the material from which the heat exchanger will be formed must have a good an indicator of thermal conductivity.

The most popular types of pipes for these purposes are:

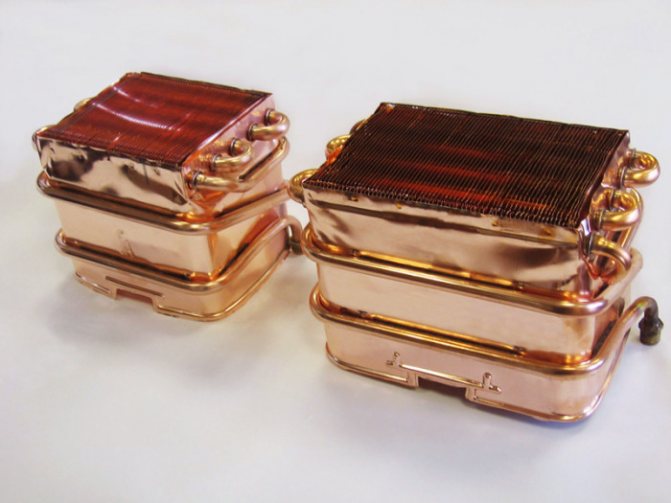

- copper products, the thermal conductivity of which is 380;

- pipes made of steel with a thermal conductivity equal to 50;

- elements made of metal-plastic, the thermal conductivity of which is equal to 0,3.

Most often used copper pipes, from which a high-quality coil with all the necessary elements is obtained. The material is plastic, therefore, if necessary, it can be given absolutely any shape and configuration, for which the bending process is used. It is considered quite simple, so it is easy to implement all the stages with your own hands. Also, copper pipes differ in that they are easy to various fittings are connected.

However, often, for full heating in each room of the house, the owners prefer to use improvised elements that have already served for other purposes to connect to the stove. For this, old heating radiators or instantaneous water heaters can be used, however, work with these objects hard enoughmoreover, they will not provide perfect heating result.

Methods for making coils

There are three main schemes for obtaining coils of boiler heating surfaces (Fig. 7): element-by-element, whip and by the method of sequential build-up. Regardless of the method, the technological process for the manufacture of coils includes: incoming inspection of pipes; sorting the original pipes by length; development of schemes for cutting pipes into elements; cutting of pipes, trimming and stripping of pipe ends. We choose the element-wise method.

Figure 7. Element-by-element diagrams for the manufacture of coils

With the element-by-element manufacturing method, prepared straight pipes are first bent on machine tools, followed by plating, then the bent elements are welded together into a coil (Fig. 7).

Structural elements of equipment

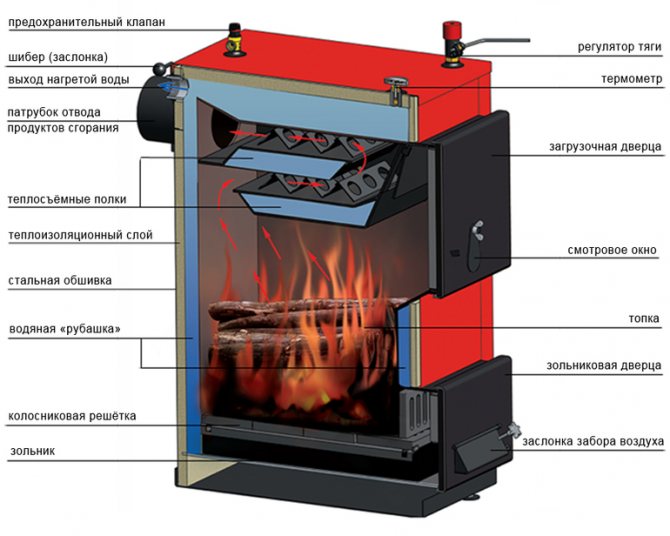

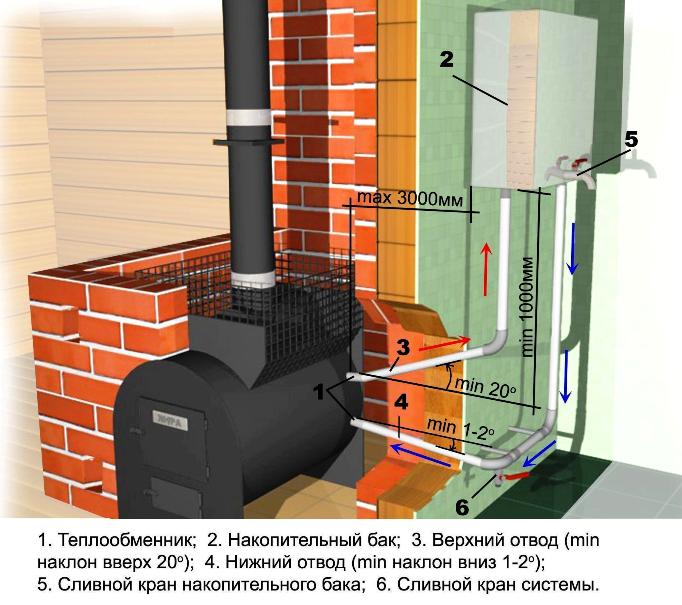

As a rule, a holistic system is used to create a full-fledged home heating. It consists primarily of a metal tank, having a fairly substantial capacity. Special pipes are connected to it. This element does not come into contact with open fire in any way. Furnace equipment is used to produce water heating, after which it enters the separate rooms of the building along the coil. In this case, uniform and high-quality heating of the entire house can be provided. Here it is important to correctly connect the equipment to the oven, and the device itself can be connected outside or inside ovens.

Furnace heat exchangers

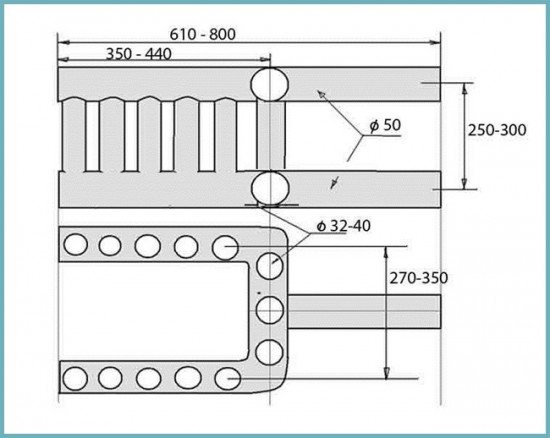

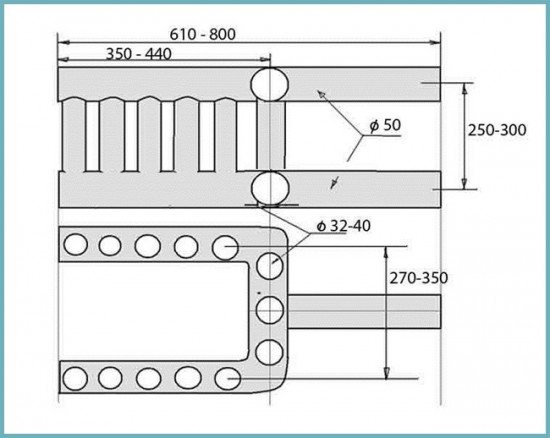

Coil arrangement diagram

The diagram shows one of the coil options. It is good to place this type of exchanger in heating and cooking stoves, because its structure easily allows you to place a stove on top.

In order to reduce the complexity of the manufacturing process, you can make some changes to this design and replace the upper and lower U-shaped pipes with a shaped pipe. In addition, vertical pipes are also replaced with rectangular profiles if necessary.

If a coil of this design is installed in ovens where there is no hob, then to increase the efficiency of the exchanger, it is advisable to add several horizontal pipes. Water treatment and withdrawal can be done from different sides, it depends on the design of the furnace and the device of the water circuit.

Reasonable choice of design

It is not so easy to choose a high-quality and suitable heat exchanger in all parameters, since in the modern market various elements are presented in numerous varieties. It is important to be guided by the fact that the entire structure should provide uniform and constant heating of the premises. At the same time, it is important that the elements are created from high-quality materials that are resistant to various influences, since in this case the equipment will last a long time, during which there will be no need for regular and complex repair work.

It is important to choose the correct coil. Recently, coil-registers are considered the most popular. They are created from pipes, the diameter of which is approximately 45 mm.and they also have smooth walls. In appearance they are similar to L-shaped lattice... They are made using not only smooth pipes, but also shaped ones. The hot water outlet, as well as the return, can be connected to such coils from different sides. However, here it is important to navigate what design features the stove itself has, as well as how it is easiest to do the piping in the heating system with your own hands.

Quality indicators

Quality indicators are used to assess the operational merits of the unit, the main ones being: technical level, reliability and durability, structural, aesthetic and ergonomic characteristics of the unit.

A. Technical level.

Distinguish between absolute, relative and prospective technical levels.

The absolute technical level of the product is characterized by its performance. Their number should be minimal. In order to avoid multiplicity and ambiguity in assessing the absolute level, it is necessary to restrict ourselves only to the most important of them - productivity, efficiency, process continuity, and the degree of automation.

The relative technical level characterizes the degree of perfection of the product when comparing (according to the relevant indicators) its absolute technical level with the level of the best modern world - domestic and foreign - samples and models of a similar purpose.

The prospective technical level determines the planned and planned trends in the development of this industry in the form of a set of its prospective indicators.

B. Durability and reliability.

These indicators are the most important quality indicators.

Durability - the property of the unit to remain operational with the shortest possible interruptions for maintenance and repairs to destruction or to another limiting state.The main quantitative indicators of durability are technical resource and service life.

Technical resource - the total operating time of the unit for the period of operation.

Service life - the calendar duration of the unit's operation until destruction or until another limiting state (for example, before the first major overhaul). The service life is limited by the physical and moral deterioration of the unit.

Reliability is a property of the unit, determined by the reliability, durability and maintainability of the unit. Quantitative indicators of reliability: operating time, probability of no-failure operation, availability factor.

Operating time - the duration or volume of work of the unit, measured by the number of cycles, the number of manufactured products or other units.

Probability of failure-free operation - the probability that no failure occurs under certain operating conditions and operating conditions within the specified duration of operation. Availability factor is the ratio of the unit's operating time in units of time for a certain period of operation to the sum of this operating time and the time spent on finding and eliminating failures during the same period of operation.

B. Ergonomics and technical aesthetics.

Creation of modern heat exchangers that meet the best models and world standards for quality, ease of maintenance and appearance. The design of an industrial heat exchanger should be based on technical conditions and, at the same time, on the requirements put forward by new scientific disciplines - ergonomics and technical aesthetics.

Ergonomics is a scientific discipline that studies the functional capabilities of a person in labor processes in order to create perfect tools and optimal working conditions for him. Technical aesthetics is a scientific discipline, the subject of which is the field of activity of an artist-designer. The goal of artistic design is (in close connection with technical design) the creation of industrial facilities that most fully meet the needs of the service personnel, as closely as possible to the operating conditions, with high aesthetic qualities, in harmony with the environment and the situation.

The attractive appearance corresponds to a generally rational and economical design. The appearance of a product depends to a large extent on its color. Color is the most important factor that not only determines the aesthetic level of production, but also affects the worker's fatigue, labor productivity and product quality.

Design and installation rules

A coil for creating high-quality, uniform and optimal heating in the house is considered an excellent solution. If you wish, you can start building it on your own, but here it is important to consider the following rules and requirements:

- There may be voids in the heat exchanger, their size should not exceed 5 mm., because otherwise the water in the equipment may boil under the influence of hot gases from the oven equipment.

- The pipes from which the coils are created must have a wall thickness greater than 3 mm., because only then can you be sure that the elements will not burn out in any way.

- Between the wall of the furnace and the equipment itself, if it is installed inside the furnace, it is necessary to provide a gap in 12 mm., which will compensate for the expansion of the metal elements of the device during water heating.

Economic indicators

A. Thermal hydrodynamic perfection.

The power spent on pumping heat carriers in a heat exchanger largely determines the heat transfer coefficient, i.e., the overall heat output of the apparatus.Therefore, an important indicator of the perfection of the heat exchanger is the degree of use of power for pumping the coolant to ensure the required heat exchange.

The thermohydrodynamic perfection of the apparatus can be characterized by the ratio of two types of energy: the heat Q transferred through the heat exchange surface and the work N spent on overcoming the hydrodynamic resistance and expressed in the same units for all flows. Thus, the measure of the use of the work expended on heat transfer can be expressed by the ratio

E = Q / N

The higher the value of E, the more, all other things being equal, the heat exchanger or its heat exchange surface is more perfect from the thermohydrodynamic (energy) point of view. The energy coefficient E is a dimensionless quantity, therefore the numerator and denominator of the expression E = Q / N can be attributed to an arbitrary, but the same unit, for example, to a unit of heat exchange surface (heat index), to a unit mass of a heat exchange surface (mass index) or to unit of volume (volumetric indicator). When comparing apparatuses, the value of E can be related to all the heat and to all the work expended, or to a unit surface, mass or volume of the apparatus.

The analysis shows that, all other things being equal, a change in the speed of the coolant has a different effect on various quantities characterizing the operation of the heat exchanger: the heat transfer coefficient changes in proportion to the speed (or flow rate) in the power of 0.6-0.8, the hydrodynamic resistance in proportion to the speed in the power 1.7-1.8, and the power for pumping the coolant is in the 2.75 degree.

With an increase in the speed of the coolant, the power for pumping it grows much faster than the amount of transferred heat, i.e., for a certain apparatus or a certain heat exchange surface, the value of the energy coefficient E decreases with an increase in the speed of the coolant. Therefore, the absolute value of the coefficient E cannot serve as a measure of the thermohydrodynamic perfection of a heat exchanger, but is useful only when comparing two or more devices.

B. Coefficient of efficiency.

The thermal indicator of the perfection of the heat exchanger is its efficiency (efficiency):

n = Q2 / Q1

where Q1 is the maximum possible amount of heat that can be transferred from a hot coolant to a cold one under these conditions; Q2 - the amount of heat transferred from the hot coolant to the cold one, or the heat spent on the technological process.

The maximum possible amount of heat, or available heat, depends on the initial temperatures and the water equivalents of the heat transfer fluids.

The main nuances of work and use

Most often, stoves in buildings are used exclusively for heating the house. However, they are often used to form hot water supply in a building. In this case, the heat exchanger should receive no more 10 percent from the generated heat from the furnace equipment.

The coils should be made of high-quality pipes of a suitable diameter, then they can provide optimal heating of various rooms in the structure. Therefore, it is important to approach this issue responsibly. Also, the material from which the pipes are made must be resistant to high temperatures, since it is used to create a heating system.

Thus, the use of a coil is considered the optimal and appropriate solution for a house in which a stove is used for heating, which is not able to independently provide uniform and efficient heating of every room in the building.