Used for cooking various assortment of bakery products: rolls, loaves, pies, sweet dishes and even pizza.

Furnaces are ideal for optimizing work large scale production and for home use.

Odnoklassniki

Requirements for ovens for baking bread

Basic requirements for devices intended for baking:

- fire resistance;

- tightness;

- thermal insulation;

- mechanical strength;

- profitability;

- hygiene;

- cooking speed products;

- ergonomics;

- aesthetics.

Constructions and design of electric furnaces

| 2.1 Electric arc furnace power supply circuit |

Large electric arc furnaces are a powerful consumer of electricity, therefore, electric arc furnaces are included in power systems that unite several power plants.

To reduce losses in power lines, high voltage energy (35-110 kV) is supplied to the workshop step-down substations. This voltage from the high-voltage switchgear is fed through a line individual for each furnace to the furnace substation, which houses the furnace step-down transformer and auxiliary equipment. After lowering the voltage to 110-600 V, the current is supplied directly to the electric furnace. The current strength in this section of the electrical circuit reaches tens of thousands of amperes, as a result of which significant power losses take place in the section from the furnace transformer to the electrodes. To reduce these losses, the furnace substation is brought as close as possible to the furnace, and the section of the circuit from the transformer to the electrodes is made as short as possible, therefore this section is called the short network of the furnace. Thus, the electrical diagram of electric arc furnaces includes the following equipment:

- a furnace with electrodes, actuators of the furnace power regulators and a bath with molten metal;

- step-down transformers, together with which chokes are placed;

- a short network connecting the secondary winding of the transformer with the furnace electrodes;

- switching, measuring and protective equipment.

Fig 2.1.

Furnace electrical equipment diagram [3]

Legend: 1 - air disconnector, 2 - main switch, 3 - choke, 4 - switch, shunt choke, 5 - furnace transformer, 6 - transformer oil tank; 7 - low voltage copper busbars, 8 - flexible cables, 9 - water-cooled tubular current leads to electrode holders, 10 - arc furnace

Fig 2.2

Single-line block diagram of the arc furnace power supply;

Legend: KV - cable gland, VV - air inlet, R - high voltage disconnector, VT - voltage transformer, VM - power switch, TT - current transformer, Dr - choke, ШВ - shunt switch, PT - furnace transformer, PSN - voltage step switch, - star-delta switch, EP - electric furnace, 3 - earth

In this scheme, power from the high voltage line is supplied through a cable or air entry. Cable gland (KB) is used for voltages up to 35 kV. At higher voltages, an air inlet (BB) is used.

The high-voltage disconnector P can only work after disconnecting the furnace transformer PT with the power switch VM.

Measuring transformers for voltage VT and current CT are used to lower the voltage and current to the values for which the measuring instruments and other equipment are designed (usually up to 100 V and up to 5 A).

The VM power switch is one of the most critical devices in the electrical part of the furnace. Working automatically, it must instantly (0.1-0.15 s) turn off the installation in the event of an emergency short circuit on the high voltage side or after a set delay (3-5 s) turn off the installation in the event of an operational short circuit of electrodes with metal in the furnace. In addition, with its help, all the operational switching on and off of the installation during its operation is carried out.

Choke Др is designed to limit operational short-circuit currents and to ensure continuous burning of arcs. After the termination of large inrush currents during melting of the charge, the choke is shunted by the switch ШВ. In large furnaces with significant inductive resistance, a choke is not used.

The furnace transformer PT lowers the high voltage to the values required during the melting process. All switching of the transformer windings are performed from the high voltage side, since in this case the current is less and, accordingly, the dimensions of the contact elements are smaller. The switch switches the three-phase high voltage windings from the "delta" connection to the "star" circuit, while the voltage on the secondary windings of the transformer decreases by times. The switching of the secondary voltage stages is achieved by reducing the number of turned on turns of high voltage windings using the PSN switch. In large furnaces, all transformer switching is carried out under load.

| 2.1 Electric arc furnace power supply circuit |

Types of ovens for baking. Why is wood burning preferred?

The range of devices is quite wide:

- Deck bakery. It is used to make ordinary bread and other pastries, most often from rye and wheat flour. Its structure consists of several tiers to which heat is supplied.

- Hearth. It is used for the preparation of pastry and yeast dough products. It is most often found in restaurants or in manufacturing. The design feature is the presence of hearths on which the workpieces move, which ensures uniform baking.

Photo 1. Hearth modular bread oven of the E series from the manufacturer Salva. Equipped with three cameras.

- Convection. It cooks not only traditional bread products, but also fish and meat. The device works on the principle of convection. It is used for both industrial and household purposes. Quite easy to operate.

- Tunnel. They are widely used in large continuous production. Cookies, buns, bread. Equipped with self-cleaning and oil supply systems.

- Electric bakery oven. It is the most cost-effective and economical. Designed for baking a huge range of products and cooking fish and meat dishes. Automatically maintains the optimal baking temperature.

- Rotary. Designed exclusively for confectionery. The main types of dough for such constructions are yeast, frozen and butter. The principle of operation is based on rotary circulation of hot air.

Photo 2. The process of loading a batch of bread into a large rotary oven from the manufacturer ENKOMAK.

- Wood burning. Products in it are impregnated with the aroma of firewood, which increases the cost of finished products. The most economical, withstands the highest temperatures. It is considered environmentally friendly. It runs on wood and has many advantages.

Benefits wood-fired ovens:

- giving natural aroma smoke to the finished product;

- preservation of performance in the field in the absence of electricity;

- energetic competitiveness.

At home, ordinary electrical devices or wood-burning ones are most often used.

Photo 3.A wood-fired oven for baking bread can be installed in the yard, it is more mobile than an electric one.

Features of the electrical circuit of the resistance furnace

Considering the electrical circuits of resistance furnaces, equipment of two types can be distinguished. The main difference is the way of influencing the processed samples:

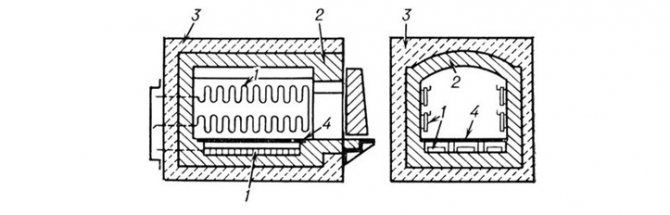

1. Indirect heating... The devices are suitable for melting metals and other things. The structure consists of:

- Heating parts (no. 1).

- Lining (No. 2).

- Heat insulating layer (No. 3).

- Heat resistant hearth (no. 4).

Indirectly heated resistance furnace design

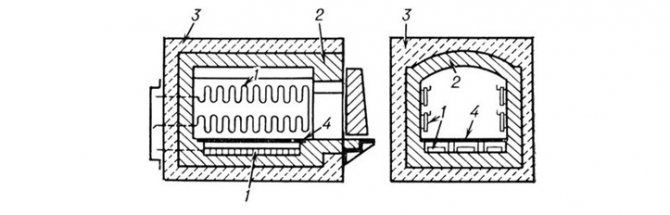

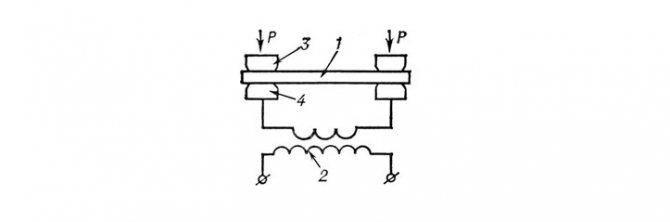

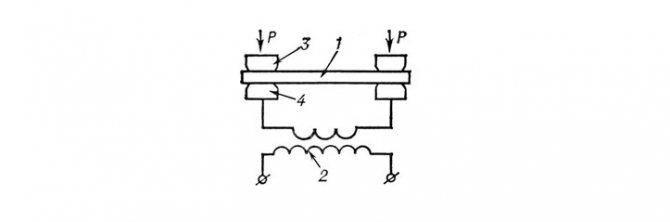

2. Direct heating... Electricity is converted into heat directly in the heated product. This allows you to reach the desired temperature in a short time. You can see the design of such equipment below, where:

- Sample to be processed (No. 1).

- Step-down transformer (no. 2).

- Contacts (No. 3 and No. 4).

Direct heating resistance furnace design

Muffle furnaces for ceramics firing, jewelry, mini and other models with a muffle are used for:

- Remelting valuable metals.

- Aging surfaces.

- Firing of glass and ceramics.

- Drying materials with high thermal conductivity.

Wood-burning stove device

The wood-burning stove must have chimney, which will ensure the removal of gases. Her power depends on size and power consumption. The fire affects the coating of the device itself, which gives off heat to the food.

Important! It is convenient not only for creating baked goods, but also for heating premises.

The main elements of the device:

- a heating element;

- window;

- belt or conveyor for products;

- steam humidifier;

- chimney.

Fuel

Mainly woodpressed pallets, fuel briquettes or peat... The advantage of firewood is its long-term preservation of heat, long-term support of the combustion process and environmental friendliness.

General building rules

The process of building an oven for making bread is not particularly difficult, but at the same time all stages are performed sequentially. At the initial stage of construction, it is important for the future owner of the stove to outline the overall dimensions of the building, the furnace door, and also to decide on the bread chamber, with its volumes and capacity. The second important step is to build an ordering scheme. Depending on how the masonry will be laid, the appearance and performance of the furnace will depend. The order is detailed in the diagrams, which are not difficult to find, and even more so to understand the structure of the work according to the drawings.

An important part in the construction of a furnace is the calculation of the consumption of the materials used.

Basic recommendations for choosing

When choosing a wood stove, you need to understand purposes of exploitationand appliance: industrial or home.

Go for a leaner and more compact version if you're cooking for family... It is unlikely that you need the amount of products that, for example, a tunnel oven produces.

Pay attention to kitchen area... Some devices take up a lot of space due to their size and the possibility of connecting a chimney.

Depending on the type of oven, it can cook not only bread, pizza, pies and pastries, but also first, second courses, fish or meat.

Types of brick ovens

Electrical devices

Bread ovens are conventionally divided into several varieties, depending on the structure and additional characteristics. It is believed that this type of construction is the most cost-effective and convenient to use. It is convenient to use electric ovens at home, and the cooking process does not take much time, the principle of operation is the same as that of a multicooker. It is necessary to select the desired program and pour the ingredients into the bowl, after a certain period of time, pick up the finished product.

Wood burning devices

This type is especially relevant for areas where there are problems with the supply of electricity and all cooking and heating occurs due to structures that are fired when firewood is supplied. The wood-fired bakery oven has the following positive points:

- provides a unique taste and aroma of freshly baked sourdough bread;

- the ability to bake buns and bread in large batches;

- other dishes are also cooked in bread ovens;

- the dimensions of the wood-burning structure, as a rule, are not very large, so it can be built in any convenient place.

Brick devices

It is an ideal option for country houses and summer cottages. Brick ovens allow you to bake various types of bread in just half an hour. After completing the baking process in a well-melted structure for another 8 hours, you can prepare many other dishes such as jams, desserts, etc.