Installation of cast iron heating radiators

The market for heating devices is striking in its diversity. But the familiar cast iron radiators are still popular due to their many advantages. They are durable, corrosion resistant, easy to use and very durable. But even the most reliable device may one day require replacement. The question of how to hang a heating radiator on the brackets can be solved independently. The main thing is to have experience, the necessary materials and take into account some of the nuances of installation.

Modern cast iron radiators - an example of style

- Features of selection and installation

- Preliminary preparation

- The main stages of independent work

- Decorative design of radiators

pros

Replacing cast-iron radiators with bimetallic (metal) ones is justified for several reasons:

- Modern appearance - bimetallic ones look more aesthetically pleasing and are suitable for various interiors of residential or office premises.

- Reduced weight bearing - cast iron batteries are much heavier than metal ones, they require good fastening and a high-quality wall that can withstand the massive weight of the structure.

- The need for rapid heating of the room - bimetal heats up quickly and quickly gives off heat to the room, cast iron heats up for a long time itself, and only then begins to give off heat.

- High water pressure in the heating system - cast iron radiators are capable of withstanding pressure up to 10-12 atmospheres, and bimetallic ones are more stable - about 20 atmospheres or more.

- The possibility of extending the radiator or repair - a cast iron structure cannot be repaired in case of breakdown, while metal structures can be changed in sections, adding or reducing their number.

- Ease of installation of the radiator - the installation of a heavy cast-iron structure cannot be performed alone, and a light modern version of bimetal can be mounted without assistance.

- Resistance to water hammer - cast iron, due to its fragility, is not able to withstand water hammer, bimetal structures are able to withstand almost any pressure drops.

Connection sequence

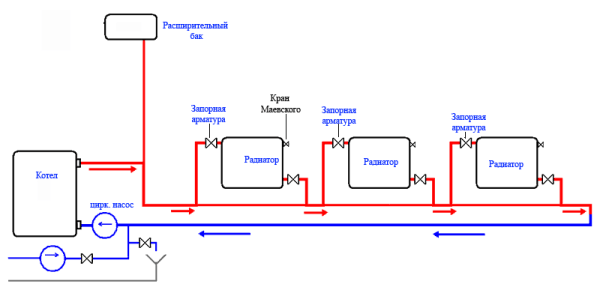

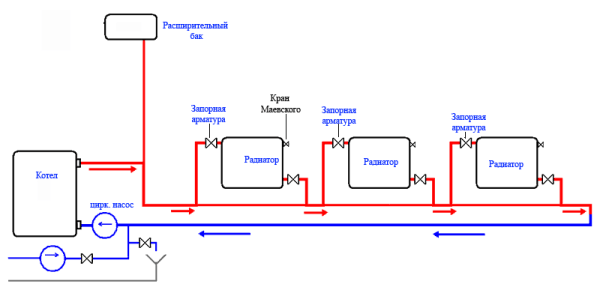

The most crucial moment in installing batteries is their connection to the heating circuit and subsequent check. In order for all the work to be carried out efficiently, it is necessary to follow the sequence of installing the cast-iron radiator.

- The heating circuit is preliminarily turned off, the supply of the coolant to the apartment is stopped, followed by its draining from the pipes using a circulation pump.

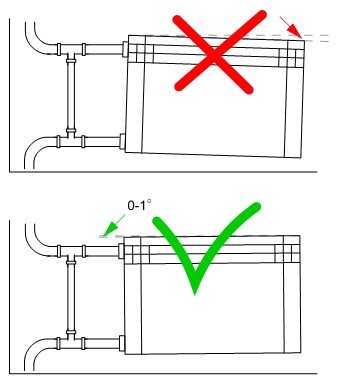

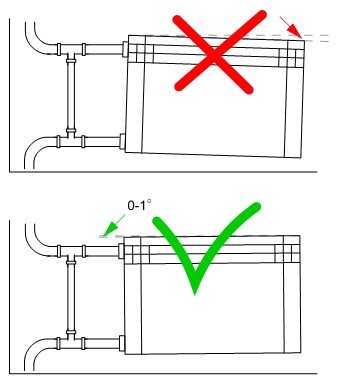

- The battery is hung on brackets with checking its horizontal and vertical position with a building level.

- The plugs are unscrewed from the device.

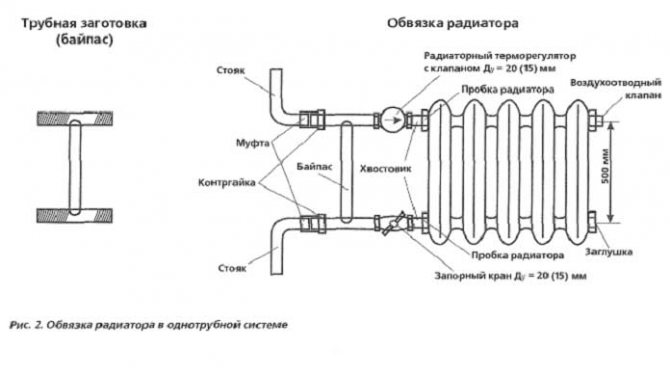

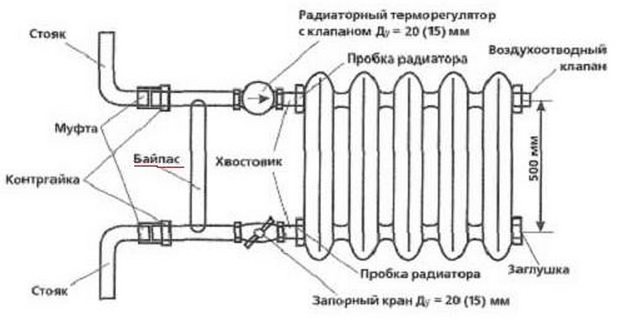

- In the event that the lateral connection diagram of cast-iron heating radiators is "introduced" into a one-pipe circuit, then a bypass with a valve must first be installed and connected. If the system is two-pipe, then squeegees with cranes are used.

At the last stage, he installs the Mayevsky crane on cast-iron radiators.

After connecting all heating elements, a trial check of the quality of work is carried out. It will show how securely the system is mounted. To do this, water is launched into it under pressure. If there is no leakage, no incomprehensible noises and knocks, then all circuit elements are connected correctly.

Installation procedure

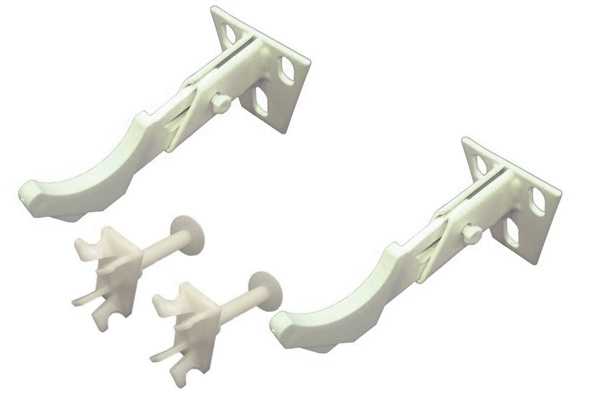

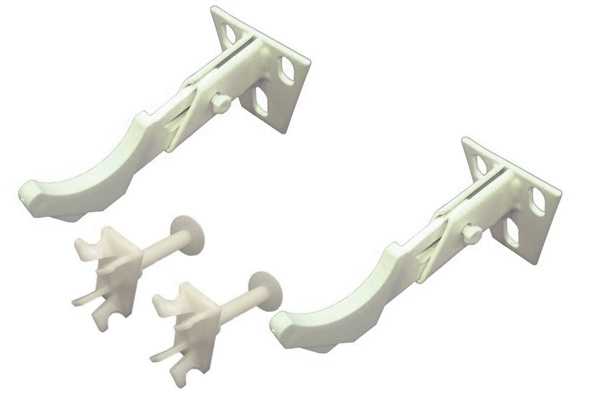

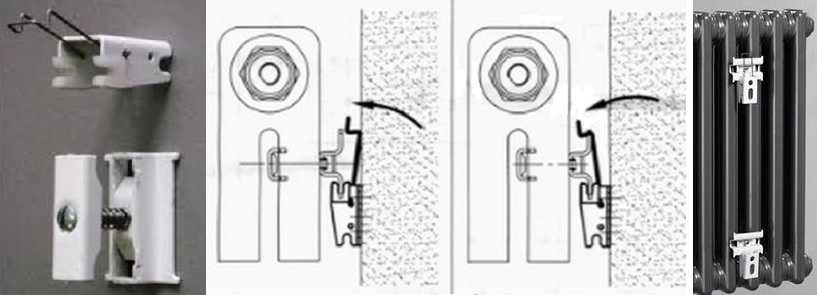

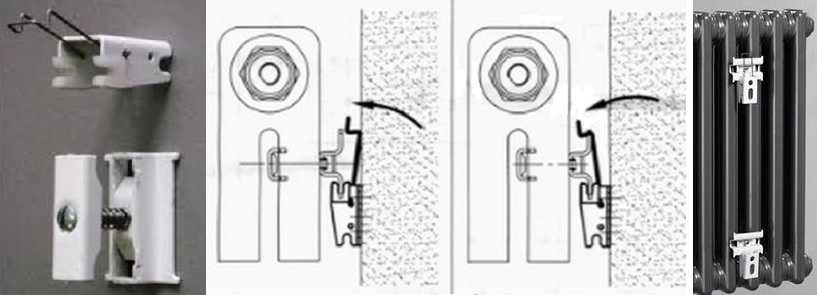

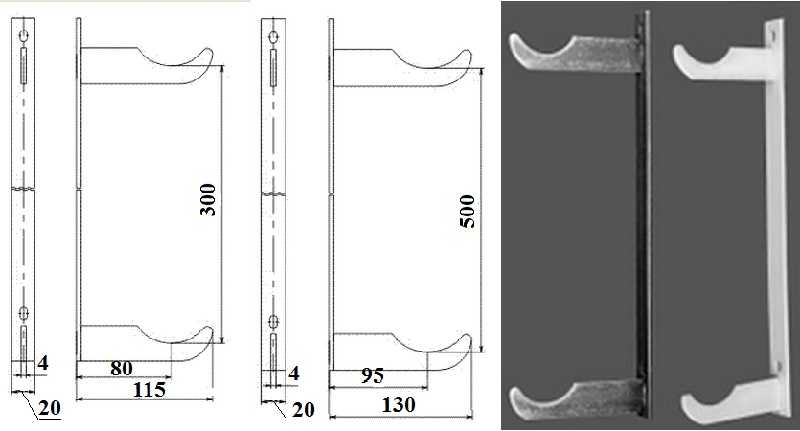

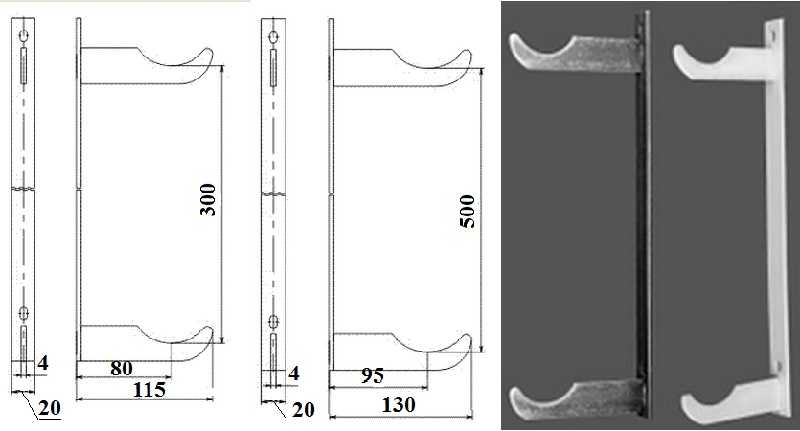

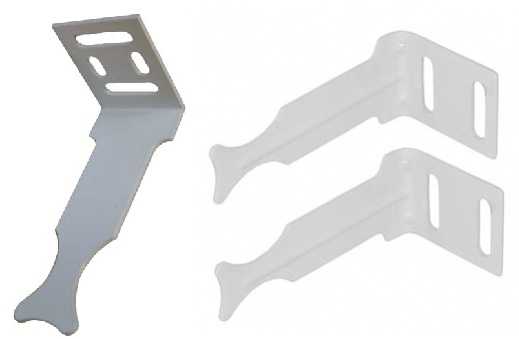

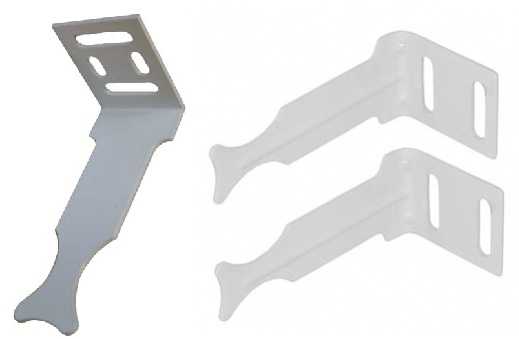

Mounting brackets for a cast iron battery

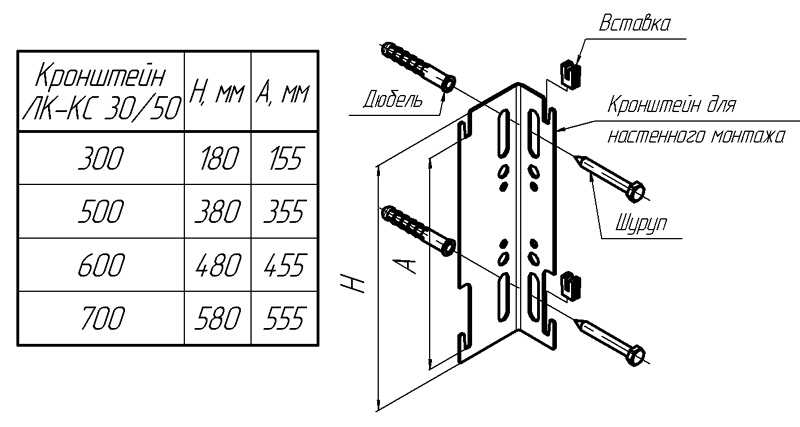

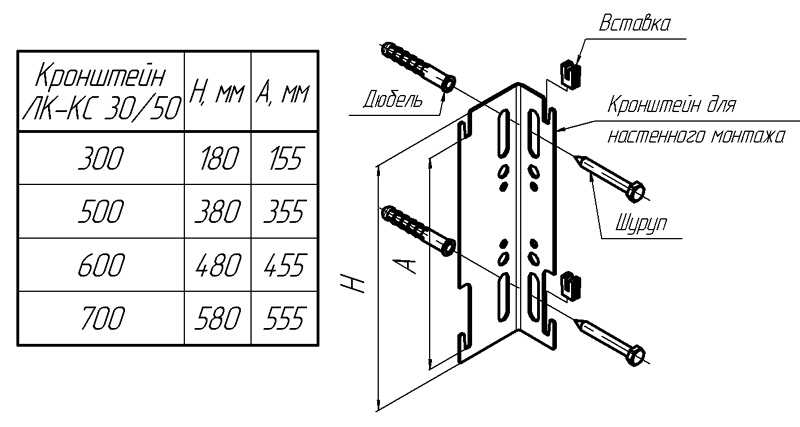

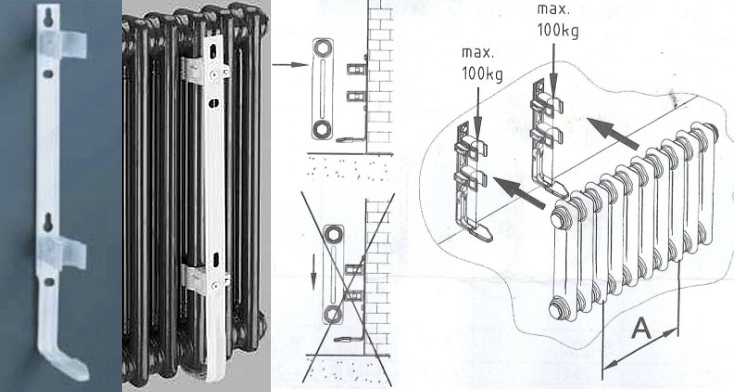

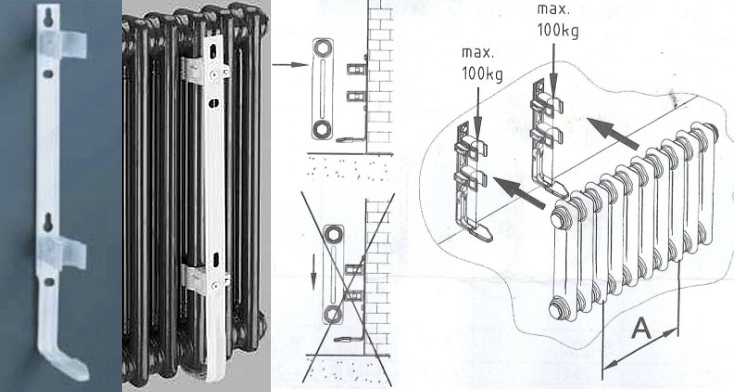

First you need to determine the required number of brackets. It depends on the area of the heater. For 1 sq.m.heating surface requires 1 bracket. Calculate the surface area of the radiator depending on the number of sections of the device and mark the wall for the installation of the brackets. After marking, check the calculations again, drill the holes, insert the dowels into them and screw in the fasteners.

Heating radiator installation

The heating circuit must be shut off and the water removed completely. The residual heating medium can be pumped out with a pump. The battery is hung on supports, for a one-pipe system, a bypass is connected. Next, the radiator is connected to the system using threaded squeegees. All joints must be sealed. For this, any sealing materials are suitable, usually tow is used. If you know how to handle a welding machine, take the opportunity and weld the joints of the sleeves and the pipeline.

After installing the device, crimping is required. This procedure is performed by professionals with the appropriate equipment. If you have a device, do everything yourself, if not, then buying an expensive device for the one-time installation of one or more radiators is not advisable. After completing the installation, check the system operation.

Theoretically, there is nothing complicated in the installation of cast-iron heating radiators, but in practice, not everything is as easy as we would like. If you do not have the necessary experience or an assistant who has already done similar work, it is still better to hire a team of plumbers. Of course, paying for their work will significantly increase the cost of the heating system as a whole, but you will save time, effort and nerves. The final decision is only yours.

Heat transfer of cast iron and bimetal

The heating power of radiators, indicated by manufacturers, rarely corresponds to reality. It depends on the temperature of the coolant and the air in the room. On average, the heat transfer of one section 50 cm high is:

- Cast iron - 140-195 W (depending on depth);

- Bimetal without air cutters - 140-155 W;

- Bimetal with air cutters - 170-190 W.

It should be noted that cast iron heats up very slowly, but also cools down for a long time. Bimetallic batteries do this much faster. Cast iron radiators allow you to maintain the temperature in the event of a heating shutdown.

Heating a room with cast-iron batteries is mainly due to radiation, not convection. For bimetallic ones - due to convection. Therefore, they quickly heat up the air in the room.

How to choose the right bracket

The main rule when buying a retainer: it must withstand the weight assigned to it. The maximum load is usually indicated in the attached instructions. The easiest way is to choose a bracket for an aluminum radiator, as it is lightweight and any type is suitable for it.

Use floor stands for very powerful batteries. But if the covering in the house is wooden, then you need to make sure that the clamps are equipped with additional fasteners to the wall. This is necessary in order to reduce the load on the boards. For light heating elements that will be located in a deep niche under the window, it is better to buy a long bracket.

It is recommended for cast iron radiators to take holders with the ability to slightly change the height, otherwise difficulties with installation may arise. The price of an adjustable bracket is not so high as to give up the convenience of mounting.

It is important that the alloy contains no toxic substances released during heating. It is not worth buying parts hand-held, especially without the appropriate accompanying documents

Please note that the lightest - the corner bracket - is only for aluminum and copper radiators

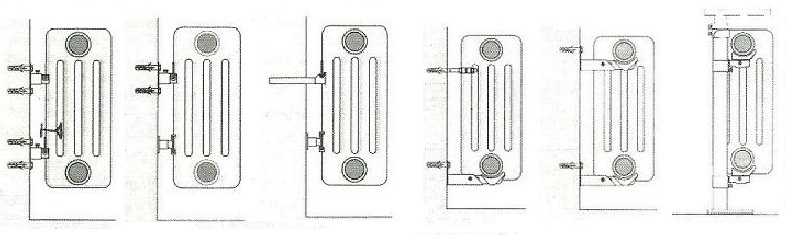

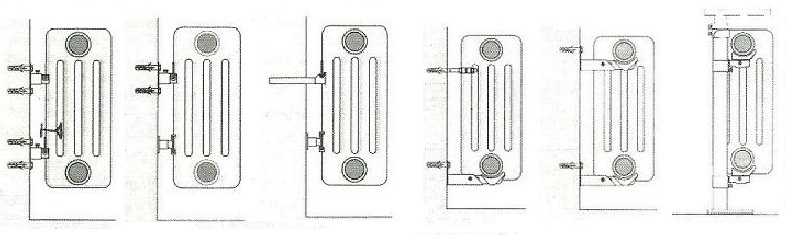

Radiator placement rules

Batteries are most often placed under a window to compensate for heat loss when cold air enters through the opening.

In this case, the following distances must be maintained:

- from the wall - 20 mm;

- from the floor - 120 mm;

- from the windowsill - 100 mm or more.

It is advisable that the window sill does not overlap the radiator too much for effective air circulation in the room. These figures are only recommendations, they can be more or less, although noticeable changes may affect the heat transfer of the structure.

To improve the situation, it is recommended to cover the wall behind the radiator with a reflective material such as foam foam. Although some masters consider this measure useless. But a beautiful decorative screen will become an obstacle for warm air, it is better to refuse it. Modern batteries look quite attractive, there is no point in hiding them.

Fasteners for steel radiators

There are two different types in this group: tubular and panel radiators. They have a different design, respectively, a different mount.

In panel radiators, brackets are welded on the rear wall, with which they are hung on the brackets. The shape of this type of fastener is different: it is designed specifically for staples.

In panel radiators, brackets are welded on the back wall

When installing panel radiators, it is necessary to strictly observe the vertical position of the brackets. High precision is required: four or six staples must accurately fit the hooks

It is also important here that the wall is perfectly flat and smooth. In general, using ordinary brackets, panel radiators are quite difficult to hang

Easier to work with other types of holders.

Standard bracket for panel radiator

Since the mass of the heater is small, it is enough to fix it on the upper brackets, install stops at the bottom that will give it a direction in the horizontal plane. They are not attached to the wall, but with hooks they cling to the bracket and simply abut against the wall. For reliability, the part that faces the wall is widened.

This is how a set of brackets for tubular steel batteries looks like: the upper collector is hung on the hooks, and plastic stops are placed below

There are also special mounting plates for easy installation. They are a strip of metal with plastic clips at the top and bottom. The brackets on the rear panel are not required when using this fastener. The strips are fixed on the wall, a radiator is inserted into them, which is held by plastic hooks.

Bar for quick mounting of panel batteries

Fasteners for tubular radiators are similar to sectional ones: the same hooks, only of a different size, often equipped with plastic pads.

There are also special fasteners with grips for SMB tubes. This is a strip of steel with plastic clips and a shelf on the bottom that serves as a support for the radiator. This mounting plate can be used when the weight of the device filled with water does not exceed 100 kg. Installation is simple: place the battery on the shelf, bring the upper edge closer to the clips. They clasp the nearest tube, a click is heard. The radiator is installed, supply pipes can be connected.

Rail for quick installation of tubular radiator with shelf and clamps

There is a second option for quick installation: SVD fasteners. It has two parts. One is attached to the radiator, the second to the wall. Then they are connected to each other and fixed with a steel loop.

Another type of holders for tubular models: two parts, one is mounted on the wall, the other is fixed on the pipe. They are pulled together with a wire retainer.

The floor mount for tubular radiators can be of several types: tubular stops, which are welded at the factory, or posts with hooks. Radiators are hung on such racks, and the racks themselves are attached to the floor.

Brackets for radiators are of different types and types: for wall and floor installation. The standard ones that come with the kit are reliable, but they are more difficult to work with.Planks and quick-fit devices save time, but cost a lot.

Fasteners for cast-iron, sectional, panel radiators

The order of installation of radiators does not depend on their type: the rules remain the same, only the fasteners change. If it is supposed to be installed under a window, the following distances must be observed: from the floor must be at least 80-120 mm, to the window sill at least 60-100 mm, to the wall - 30-50 mm. It is also necessary to determine the number and location of the fasteners.

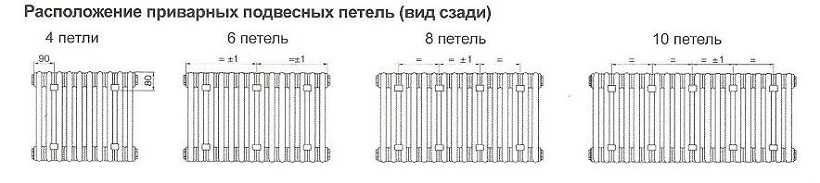

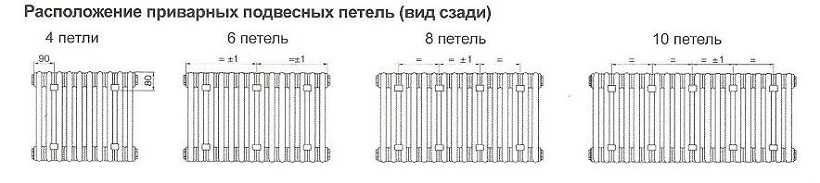

The number of brackets (hooks) per battery depends on its length. If there are few sections - up to 8-10 pieces, then two holders are required at the top, and at least one more at the bottom. If there are more than 10 sections, three supports are installed on top, and two on the bottom. For each next five to seven sections of cast-iron radiators and ten tubular and aluminum, the number of fasteners increases: one holder is added at the top and one at the bottom.

Ways to use different kinds of fasteners for sectional radiators

Advantages and disadvantages of cast iron batteries

First of all, it is worth clearly identifying all the pros and cons of cast iron radiators, because they, like any other types of batteries, have their own characteristics that should be taken into account before removing them (or, conversely, buying).

- Reliability and durability. Cast iron is unpretentious to the coolant, it will not be damaged even by large fractions or aggressive chemical impurities, often contained in water from Russian thermal power plants. The maximum allowable coolant temperature reaches 130-150 degrees. With regular flushing, this battery can last for decades.

- High heat capacity and thermal inertia. Such batteries give off heat for a long time, which after disconnection can remain in them up to one third of the original volume. However, the same feature of the material is also its disadvantage - more on this in the corresponding section.

- Great weight. Cast iron is a very heavy metal, the weight of one section of a cast iron radiator can reach several kilograms. On average, this is 2-3 times more than the weight of a bimetallic battery section, and 4-6 times more than the weight of an aluminum radiator. ...

- Price. One section of a cast-iron radiator is noticeably more expensive than a section of a bimetallic or aluminum battery similar in size and heat transfer.

- Impossibility of installation in a system with automatic adjustment. The design features of the battery and the properties of the metal will prevent the sensors from receiving up-to-date information on the temperature of the coolant and surface. When choosing which is better to put heating batteries in an apartment, be sure to take this nuance into account.

- Low efficiency. Due to the thermal inertia, much more energy and coolant will be spent on heating a square meter of area than in the case of other types of batteries. This can be completely unimportant if your heating is centralized and you pay based on the square of the house. But if you have a gas boiler, you will have to spend more of your own money, and they will go mainly to heat the battery itself, and not to increase the temperature in the room.

- Unaesthetic appearance. Note that this applies only to old batteries, but if you have just such - they are unlikely to harmoniously fit into the modern environment. In this respect, cast iron batteries of the new model are no different from bimetallic or aluminum "counterparts" - they look modern and stylish, they will perfectly fit into the interior of any apartment.

Fasteners for cast iron batteries

Since these are the heaviest heating devices, the holders for them are the most massive: they must hold considerable weight for years. These can be single or curved pins fixed to the bar. In any case, a thicker metal is used in the manufacture of fasteners for cast iron batteries. In the price lists, it usually comes with the addition of "reinforced".Can be painted (standard color is white) or not. Some manufacturers paint on request in the desired color (when ordering a radiator, specify the type of fastener and its color).

Mount for a cast-iron battery and make it reinforced: from a thicker metal

When buying, you will need to take into account the dimensions: fastening for sections of different depths is done on purpose, since it is necessary to ensure a distance to the wall of at least 3-5 cm.

In addition to brackets for cast-iron radiators, hooks are also produced. They are sold together with wall plugs. They are installed as standard: a hole is drilled, a dowel is inserted into it, and a hook is screwed into the dowel (there is a thread on one side of it).

There are mounting plates for cast iron radiators that make installation easier.

In addition to the wall mount, there are feet for floor installation. They are height-adjustable or not. The upper arcs are also different, fixing the section on the stop: there is an arc made of steel wire, and there is a chain of movably connected links. In both cases, the batteries are fixed to the support using these arcs and bolts.

Stands for floor installation of sectional radiators - any wall-mounted battery can be installed on the floor

Connection diagrams

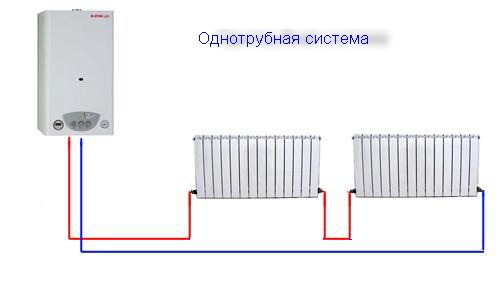

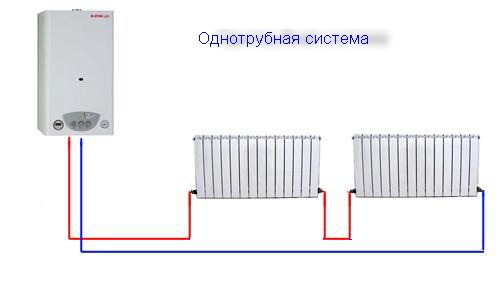

The most fail-safe scheme for connecting heating radiators in a private house with a bottling and a boiler is a single-pipe Leningrad. Heating devices are connected in parallel with the filling, which is laid along the perimeter of the room.

Somewhat cheaper in installation, but much more problematic in operation is a circuit using a series connection of batteries. Suffice it to say that their independent adjustment is impossible in this case.

Single-pipe version with series connection.

Finally, a two-pipe system involves connecting each radiator as a bridge between the supply and return lines. It is inconvenient in that it requires the already mentioned balancing - limiting the passage of heating devices closest to the boiler.

What can be the diagrams for connecting heating radiators to the supply line?

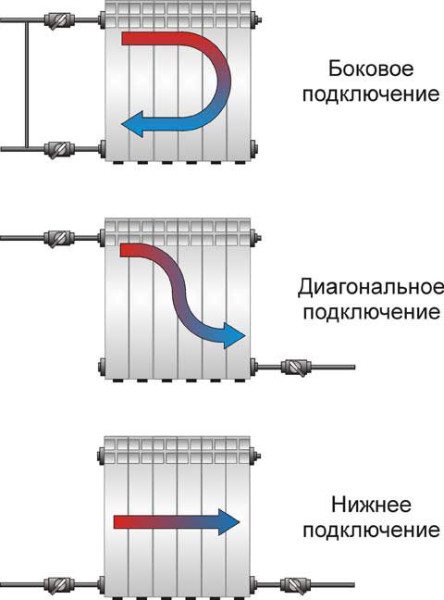

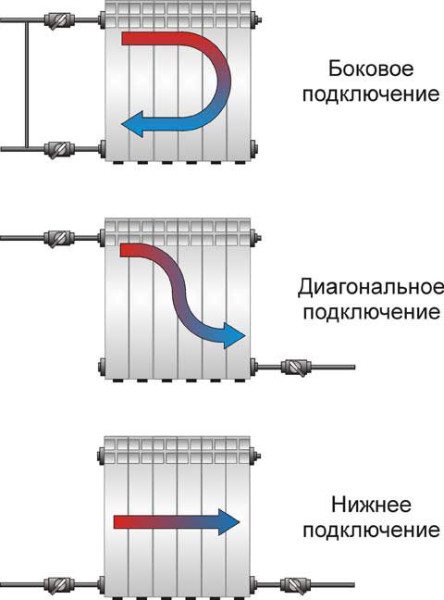

- One-sided. connections are connected to the upper and lower radiator plugs on the right or left. It is compact, but makes the heating of the device uneven: the last sections will always be colder than the first.

- From bottom to bottom. In this case, the battery must be equipped with an air vent. The advantages of the solution are that the radiator, with such a connection, does not require flushing and always heats up along its entire length.

- Diagonal. Heating of sections is even more uniform; however, the bottom corner of an instrument with a blind plug will gradually silt up.

Connection options for connections.

Which heating batteries (radiators) are better, cast iron or steel - types, characteristics

The habit of monumentality gives rise to a lot of misconceptions regarding heating systems for apartments and houses. Many apartments and houses are equipped with old type cast iron batteries, although there are more modern options. The development of new steel radiators, manufactured using modern technology, opens up many interesting possibilities in terms of design and efficiency of heating appliances.

Compare steel and cast iron radiators

Comparison of cast-iron radiators with steel is quite correct, since both groups of products belong to heating devices suitable for widespread use. At the same time, steel and cast iron have significant differences in properties that affect the performance characteristics of finished products. Let's consider the key features of each type of instrument.

When choosing a heating radiator, a potential buyer is guided by the main characteristics:

- dimensions and weight of the complete product;

- the ability to choose from different formats;

- the possibility of simple fastening, taking into account the existing standard solutions;

- wear resistance and durability, taking into account the operating conditions;

- for a radiator, the heating rate and the ability to maintain temperature (thermal inertia) are of great importance;

- strength in the event of external efforts.

For heating devices made of different materials, these indicators will differ.

Which radiators are heavier

The first thing that catches your eye when comparing cast iron and steel radiators is their weight. The former are much heavier, despite the fact that the density of most types of steel is greater than that of cast iron. The fact is that in order to obtain products of equal strength, it will be necessary to increase the thickness of the cast-iron wall in comparison with the steel one. This affects the final weight of the product - the weight of the steel radiator Harmony 1-155-3 out of three single-column sections 200 mm high will be 3.3 kg (without filling). The weight of a similar cast-iron radiator will be in the range of 5 - 5.5 kg due to the larger amount of metal.

Difference in design options and ease of installation

With the use of modern technology, the ability to shape cast iron into different shapes has expanded significantly. Now tubular and plate radiators are produced, with and without housing. There are models with a beautiful imitation of forging on the surface. At the same time, there are noticeably fewer design options for cast iron batteries due to the greater complexity of production.

The same applies to ease of installation, wall mounting - cast iron batteries require more durable parts and particularly reliable wall mounting. Tubular steel batteries do not require as much attention to the strength of the fasteners.

Durability and strength of radiators

The reaction of steel and cast iron to loads is fundamentally different. A cast iron radiator is sensitive to fracture loads, shocks, internal influences in the event of a pressure surge - water hammer. Inadvertent application of force during installation, shock or pressure drop may cause the battery to crack. The steel tubular radiator, which can last 15 - 25 years, depending on the model, transfers such loads without loss.

The durability of cast iron is undeniable, but much depends on the operating conditions. In the manufacture of steel tubular radiators, a protective coating is created inside the sections to prevent corrosion. Similar processing of cast iron is more expensive.

Thermal inertia and efficiency - cast iron or steel radiators?

A very important criterion for those who want to make the most of the heating possibilities is the thermal inertia of radiators. This property of metal has two sides: when operating a system with room temperature control, it is necessary that the radiators quickly heat up and also quickly reduce the temperature. If you expect to "drive out" the system, for example, in the country, once, so that it retains heat for some time, then you need a high inertia.

Cast iron is characterized by high thermal inertia; it heats up and cools down longer than steel. This can significantly affect the efficiency of heating that is used continuously for a long time. For rational consumption of heat energy, that is, to save gas or electricity, it is more reasonable to install tubular steel radiators of the Harmony type from KZTO.

Our findings

If we summarize all the observations, then we can come to the conclusion that a more modern and rational solution is steel tubular radiators for heating. They are more predictable in a controlled system, have less weight (less load on the walls), and can be fully adapted to the interior. During installation, this solution allows you to simplify the work and prevent the destruction of devices from cracks, water hammer, and other damage.

Modern stylish design, which is of great importance in a private house and apartment, is a huge advantage of steel products, which are produced in a wide range of shapes, sizes and color options.

Required tools and materials

Technology for unscrewing and assembling cast iron batteries: a - nipples capture the thread of sections (2-3 threads); b - tighten the nipples, dock the sections; c - mount the third section; d - group two radiators.

Replacing or installing various cast iron radiators can take place in several stages and in completely different ways. To complete this installation, you will need:

- gloves;

- protective glasses;

- gas welding;

- assembly keys;

- rubber gaskets;

- screwdrivers;

- radiator keys (short and long).

If you decide to install or replace yourself, then be very careful and follow the rules of safety and security. Welding work can be harmful.

Mounting methods for aluminum and bimetallic radiators

The products are very similar in shape. Only they are made of thinner metal. In general, brackets for sectional radiators of any type are very similar. There are universal corner brackets for aluminum and bimetallic radiators. They have a recess at the top and bottom for the collector, so they can be attached both to the right and to the left.

Special angle brackets for light sectional radiators

There are no floor-standing aluminum and bimetallic radiators. But there are racks that allow any of them to be installed on the floor. In this case, the rack is first fixed on the floor, and then the heating device is installed and fixed on it.

Floor mounting of aluminum radiators helps out if the walls cannot withstand even such a small weight (if they are made of plasterboard or aerated concrete, other similar materials).

Any sectional radiator can be fixed on such racks.

You will not be able to hang anything on the now fashionable glass wall

But then you need to pay attention to how the whole structure looks from the back side. In this case, it is more advisable to use convectors built into the floor for heating.

floor models of tubular radiators (at the same time can serve as a fence), cast-iron retro radiators.

Compliance with installation standards

Even knowing how to install a cast iron battery, you should remember why you need to adhere to the norms approved by SNiP. Maybe someone will consider this optional, and they will be wrong, since any deviations from the parameters are not just a violation of security rules, but also a decrease in the efficiency of the system itself.

The general rules for installing radiators include:

- The position of the device relative to the vertical axis of the window. The middle of the battery should line up with it. The permissible deviation should not exceed 2 cm.

- The battery must have such a number of sections that, when assembled, it occupies 75% of the width of the window opening.

- The SNiP indicates how to fix the cast-iron battery to the wall. So the distance between it and the floor according to the standards is 60 mm, 50 mm under the windowsill, and 25 mm from the wall.

When the place is chosen and all the calculations are made, you can begin the installation of cast-iron heating radiators with your own hands. This will require the tools and necessary fasteners.

What modern batteries are made of

What radiators can be supplied:

- bimetallic;

- copper;

- steel;

- aluminum.

For example, aluminum ones are lightweight, have high thermal conductivity, good heat dissipation and stylish design. Of the minuses, the masters note the sensitivity to pressure drops, the need to maintain the PH of the water. They are incompatible with copper pipes. Steel radiators have low weight, low cost, good heat transfer. Of the minuses, susceptibility to corrosion was found, it cannot be left without water. Poorly withstand water hammer, possible peeling of the coating over time.

Most popular bimetallic batteries. They serve for many years, are resistant to pressure drops, increased heat transfer.They are very easy to install, have a beautiful appearance, do not corrode. Cons: at first, slight crackling inside the system due to aluminum and steel. In addition, the product is expensive.

Important: when choosing radiators, listen to the advice of the master, he knows better which option is suitable in each specific case. You can install new cast iron batteries, they are also available, they just have a more stylish look. Cast iron heats up slowly, but also cools slowly. The battery is not capricious to the composition of the water. Of the minuses, only the old-fashioned appearance and the very heavy weight of the radiator stop it.

If the apartment is being renovated, then the batteries must be replaced at the very beginning. Although you can check the quality of the radiator only when heating is on, which means it will take several months before you can make sure of this yourself.

Placement of heating devices

It is of great importance not only how to connect heating radiators to each other, but also their correct location in relation to building structures. Traditionally, heaters are installed along the walls of rooms and locally under windows to reduce the penetration of cold air currents in the most vulnerable place.

There are clear instructions for this in the SNiP for the installation of thermal equipment:

- The gap between the floor and the bottom of the battery must not be less than 120 mm. With a decrease in the distance from the device to the floor, the distribution of the heat flow will be uneven;

- The distance from the back surface to the wall on which the radiator is mounted must be from 30 to 50 mm, otherwise its heat transfer will be disturbed;

- The gap from the upper edge of the heater to the window sill is maintained within 100-120 mm (not less). Otherwise, the movement of thermal masses may be difficult, which will weaken the heating of the room.

Bimetallic heating devices

To understand how to connect bimetallic radiators to each other, you need to know that almost all of them are suitable for any type of connection:

- They have four points of possible connection - two upper and two lower;

- Equipped with plugs and a Mayevsky tap through which the air collected in the heating system can be vented;

Diagonal connection is considered the most effective for bimetallic batteries, especially when it comes to a large number of sections in the device. Although very wide batteries, equipped with ten or more sections, are undesirable to use.

Advice! It is better to ponder the question of how to properly connect two heating radiators 7-8 sectional instead of one device of 14 or 16 sections. It will be much easier to install and easier to maintain.

Another question - how to connect sections of a bimetallic radiator may arise when rearranging sections of a heater in various situations:

The place where you plan to install the heater is also important.

- In the process of creating new heating networks;

- If it is necessary to replace a failed radiator with a new one - bimetallic;

- In case of underheating, you can build up the battery by connecting additional sections.

Aluminum batteries

Interesting! By and large, it should be noted that diagonal connection is an excellent option for any type of battery. Not sure how to connect aluminum radiators together. connect diagonally, you won't go wrong!

For closed-type heating networks in private houses, it is advisable to install aluminum radiators, since it is easier here to ensure proper water treatment before filling the system. And their cost is much lower than that of bimetallic devices.

Of course, over time, moving along the radiators, the coolant cools

Of course, you will have to try before you connect the sections of the aluminum radiator for regrouping.

Advice! Do not rush to remove the factory packaging (film) from the installed heating devices before finishing the finishing work in the room. This will protect the radiator coating from damage and contamination.

The work process itself does not take much time, you do not need any special skill or expensive equipment, you can purchase all the necessary tools at any hardware store. And do not forget, the connection will serve you for a long time and without hassle only if you used high-quality materials in your work and followed all the rules for installing the heating system.

We are talking about exactly what is indicated in this figure.

In the video presented in this article, you will find additional information on this topic.

Reasons for the required replacement

The following reasons should push the owners to replace the heating radiator:

- A small number of radiators are located on the required area. Because of this, the room is not heated properly.

- Lack of thermostat.

- Poor space heating.

- The heating system model has long been outdated and has become unusable.

- The presence of corrosion on the radiator, various damage in the form of cracks and system leaks.

All these factors lead to the fact that the temperature in the space is constantly low, and there is simply no way to regulate the indicators on your own. There is also a high probability that sooner or later the neighbors from below will be flooded. As a result, a lot of honestly earned money is paid for heating, but there is no heat, as such, at all. Of course, it is recommended to replace the heating radiator in the spring or summer, when the whole house is turned off. But if there is no way to wait, then this procedure can be performed during the heating season. But then the whole house will have to be disconnected from heating for a while. In order not to pour boiling water over the neighbors, you should ask qualified specialists for help.

This is the only way to change the heating radiator without any problems and in the shortest possible time. Modern models of heating elements weigh much less than old ones. In addition, they have a high level of heat dissipation and a stylish design. The problem may also be that the inside of the radiator may have an air lock or a blockage. Also, the temperature that is supplied to the room may simply be insufficient. You can find out from the locksmiths or in the housing office. They are probably aware of how powerfully the boiler room supplies heat to the room.

Installing cast iron heating radiators with your own hands

- Required tools and materials

- Stages of installation work

Cast iron radiators are a fairly popular battery, with the help of which heating is carried out in multi-storey buildings. This is due to the fact that cast iron batteries have undeniable advantages over other types of heating. In addition, most of the installed batteries in homes have already expired and now need to be replaced. That is why information on the installation of cast iron radiators is very relevant. Installing heating systems is not an easy task, but it is quite feasible for business executives.

Radiator piping in a one-pipe system.

An important role is played by the site on which the installation of cast-iron radiators will be carried out.

The surface composition of the installation site will be reflected in the heating installation stages. Installation of devices can take place on a wooden wall. In this case, you will need one strip and one stand for each radiator for installation. Batteries can also be installed on a brick plastered wall. You will need a bracket, a window sill and a niche here.

Also, a lightweight wall can become a place for installation. Here you will need a solid support on which the heater will be installed.It should be noted that it is advisable to choose a place for installing a cast-iron battery with the condition of convenience, not beauty. To add beauty elements to heating appliances, you can resort to simpler methods of decorating and decorating batteries, for example, using a rattan grill.

Preparatory work

In order to choose the right parts and calculate their number, you should know the type of wiring of the heating system - one- or two-pipe. In a single-pipe, the heated coolant rises along the riser, and the heating devices are connected to the descending line. In a two-pipe system, the coolant moves from the heater to the heating devices and vice versa. One line is designed to supply hot water, the second is to return the cooled coolant to the boiler. There are two ways to connect system elements - horizontal and vertical.

All the nuances of the connection should be clarified before starting work. Before installation, you need to drain the water from the system, dismantle the old heating devices, remove the fasteners on which they were held. The supply of hot coolant to the system must be stopped before the end of the work.

Assembling cast iron heating radiators

The first step is to group the sections. To do this, you need radiator keys. The device is fixed on a workbench; radiator keys must be inserted into the lower and upper holes so that they rest against the internal projections. Both nipples must be turned at the same time in order to avoid skewing the sections, therefore, the manipulation is performed with an assistant. The nipples should be greased with linseed oil, and gaskets should be put on them. The keys are rotated in the opposite direction to the thread. If it is left, then turn to the right, and if it is right, to the left. You need to screw in 1-2 threads.

Hydraulic tests of the finished structure are carried out at a special stand, where a pressure of 4-8 kgf / cm2 is created using a press. The performance of the device is checked by a pressure gauge. If its indicators begin to decline, it means that either defective sections are connected, or the work was performed poorly. In the first case, the elements are replaced, in the second, the nipples are tightened. If minor damage appears, it can be repaired with epoxy adhesive. If the connections are incorrect and the joints are leaking, the gaskets should be changed.

Painting the radiator after assembly

After the tests, the heater is painted and dried. Two thin coats of paint must be applied to obtain a durable and even finish. As a result, radiators must meet the following requirements:

- Heat-resistant coating of the device body. It must withstand a temperature of 80 degrees, without softening and not emitting harmful substances into the atmosphere.

- The painting should be of sufficient quality to protect the radiator from corrosion as much as possible.

- The selected composition should not change in color.

Experts recommend using alkyd enamels as a coating, because after drying, they are harmless and do not poison the air during operation. Option - acrylic compounds. They do not crack, do not change color and are resistant to heat. Both types of formulations have their advantages: alkyd enamels are cheaper, acrylic-based paints are more durable. You can also use water-dispersion paints, which bear the manufacturer's mark that they can be used for painting heating devices.

How to correctly determine the location of the radiator

Heating devices are usually placed under windows at a height of at least 6 cm from the floor and 5-10 cm from the bottom of the window sill. The distance to the wall should be at least 3-5 cm. The pipes of the system are placed under a slight slope, which is made in the direction of movement of the coolant. If there is no slope or distortions appear when installing a cast-iron radiator, air will accumulate in the batteries, which will have to be removed manually.An “airy” radiator will not be able to warm up normally and give off heat. The center of the device should coincide with the center of the window opening plus or minus 2 cm.

Do I need to change cast iron batteries during repairs?

Dismantling old plumbing and communications during a move or renovation is a common thing. However, such a component of the house as cast-iron batteries is not always changed in such cases. The reason is the well-established opinion that old cast-iron batteries are good and nothing can be better than them. But is it really so? What are their advantages and disadvantages, and is it worth changing cast-iron batteries to modern ones? For those who are puzzled by this question, the Santechbomba store has prepared useful material that will help make the best decision.

Installation of cast iron heating radiators

When mentioning heating, the first image that appears in the imagination is the large cast-iron radiators that used to be in almost all apartments. They were all the same, rough in shape, gray in color, which was simply impossible to lift. Pipes went to them across the room. They tried to refine their appearance by painting them with white paint. But it should be noted that it was these radiators that could happen almost forever, and, perhaps, it was they who were and remain one of the most heat-conducting radiators among the existing heating devices.

Modern manufacturers did not stop producing cast iron heating radiators. It's just that their design has changed radically. Now on the market you can see both antique and modern design radiators.

In most urban heating systems, pressure is usually very high, and the heat carriers, on the contrary, are not of very good quality. And cast iron heating radiators fit perfectly into this heating network. Thick cast-iron walls of radiators can easily withstand high pressure for several decades, their use is possible even if steam with a temperature of about 150 degrees is used for heating. And corrosion to cast-iron radiators is not terrible.

Installation diagram of a cast iron radiator

When water is drained in late spring for preventive maintenance, they tolerate the airing of the system well. In the event of a power outage, cast iron radiators continue to generate heat, as they cool much more slowly than other radiators made of other materials. Video

Of course, cast iron radiators have some drawbacks, but there are no perfect things. The first drawback of cast iron radiators is their weight. They weigh a lot, which means that their installation will require a lot of physical effort. You cannot install such batteries on your own. Since this type of radiator is usually hung on a wall, you should make sure that the wall is capable of supporting the weight of the radiator, which, after installation, will also be filled with water. It may be worth purchasing a radiator model with additional legs.

The larger the size of the cast iron batteries, the higher their heat capacity, the slower they cool down. If you purchase narrow cast-iron batteries, then their weight, of course, may be less, but also heat transfer and inertia will decrease.

Despite the disadvantages, the advantages are still too good to refuse to install these wonderful heating appliances. In addition, modern manufacturers produce radiators of different shapes and colors. The design of modern radiators is not only accordions familiar to our understanding, models with a smooth surface are produced, with widened gaps between the sections. The widening of the gaps allows the heat dissipation to be increased to some extent. There are also models made in the form of columns.

Cast iron batteries will be relevant for a very long time. And thanks to the design work on their appearance, they can easily complement any interior.But the most important thing is that the house will be very, very warm.

How useful was the information for you?

Replacing cast iron batteries with bimetallic radiators

The article describes the procedure for replacing cast iron batteries with bimetallic radiators, with the replacement of metal pipes, polypropylene pipes. I will share my experience on how to do all the work as quickly and efficiently as possible. I will reveal the advantages of bimetallic radiators and the secrets of their long service.

Replacing batteries is not cheap, but sometimes there is simply no choice, because old batteries do not perform their functions in full. In a private house, replacing batteries and pipes rests on the desire of the owners. But in an apartment building, you need to take into account the desire of neighbors in this matter. After all, it is much easier to change pipes at once along the entire heating branch in order to surely see the effect of replacement.

We were lucky, because the neighbors are quite decent people, so the choice of batteries and pipes became the order of the day in all the apartments of our entrance. Our house consists of only two floors, so, probably, we live together. It is better to replace batteries in the summer or in September, until the heating season has come and the heating system is without water.

The first step was to dismantle the old heating system, consisting of batteries and pipes. The batteries were made of cast iron and fully worked out. The pipes were completely clogged, so their replacement was not even discussed, it was by itself.

To dismantle the batteries, a grinder was required, which was cut off the cast iron batteries. We did it together with a neighbor, because the batteries are very heavy. And they did not regret the sections, which affected their weight. When cutting off the batteries, a container was placed under the pipe so that the liquid that could be in the batteries escaped. The old batteries were taken out into the street. Over time, they can be scrapped.

The process of replacing pipes was hampered by the fact that in our house the heating pipes are built into the walls. Here's some theory. Therefore, the dismantling of old pipes could well have brought repairs in all apartments to zero. Therefore, we decided to do without heavy losses and not to touch the old pipes in the walls. They decided to run new pipes inside the apartment near the walls. Old metal pipes were cut as close to the wall as possible with a grinder. Subsequently, it will need to be repaired so that it is not visible.

Holes were made in the walls between the rooms, the size of the pipe. We tried to do it as carefully as possible, but it was not always possible ...

Polypropylene pipes were laid into the holes obtained using fittings: adapters, tees and corners.

It is best to fix pipes against the wall using special clamps for polypropylene pipes. The neighbor decided otherwise and fixed the pipes in a different way. That was his mistake.

The type of special clamps is much better and more accurate. You can verify this by looking at the following photos.

The next stage of work was the installation and connection of batteries - bimetallic radiators. They are made of two metals. Made of steel, which has strength, and aluminum, which has excellent thermal conductivity and ductility. The frame of the bimetallic radiator can withstand high pressure loads. The case for bimetallic radiators is made of aluminum, and its shape is ribbed-shaped. This is how the radiator is designed for better heat dissipation.

It is better to buy bimetallic radiators sectional in order to be able to select the required number of sections for each room.

You can calculate the number of sections for a specific room using the formula:

Number of sections = room area * 100 / section heat transfer

Thus, I calculated the number of radiator sections for each room. For the smallest room, I managed to install 8 sections.

Working with bimetallic radiators is a pleasure. They are so light and tidy that it won't be difficult to hang them.I note that we will need to replace batteries and pipes, as I wrote earlier:

- grinder with a cutting disc for metal;

- puncher and drill for concrete (for making holes in the wall);

- adjustable wrench;

- building level;

- thermostatic kits for connecting radiators.

Using a punch, make holes in the wall for fixing bimetallic radiators. They need to be fixed strictly according to the level so that there is no stagnation of air or water, which will affect the service life of the radiators. It is necessary to place radiators at a distance of 10-15 centimeters from the floor to ensure air flow. The distance from the windowsill should be the same as the distance to the floor. From the back of the wall, radiators are placed at a distance of 3-5 centimeters.

Battery mounting kit (bimetal): it contains all the necessary elements for mounting the radiators. Installation of radiators takes a little time, the main thing is to correctly install all the parts.

The required temperature of the radiator can be set by turning the adjusting knob according to the corresponding marks on the scale.

Installation of radiators must be done without removing the protective film from them, this will help to preserve the appearance of the radiators, without scratches or other damage. When the piping and installation of radiators are completed, you can remove the protective film.

It is necessary to check the system by curling the system with water. If there are no leaks anywhere, then all the work is done with high quality.

Indoor pipes, in my opinion, do not require additional insulation and insulation, although some of my neighbors have made foil-clad polypropylene wrapping of pipes. According to them, this is necessary so that less heat goes into the walls. Judge for yourself how it looks outwardly ...

Therefore, in my apartment, I did not do such experiments. I just decided, upon completion of the repair, to paint the pipes white.

The installation of bimetallic radiators was completed before the start of the heating season. Now it's warm in the apartment. Therefore, it is quite possible to assess the advantages of the new radiators. They just heat up instantly and give off heat perfectly. The good news is that you can regulate the temperature yourself. In general, we were pleased with the replacement of cast iron batteries with bimetallic radiators. In the future, we will consider covering the radiators with a homemade screen.