What are the pros and cons of electric welding?

Welded joints have the following advantages:

- connections of large sizes can be obtained;

- for welding, you can use a material that is similar to that of the pipe. Thanks to this, all the properties of the pipeline are preserved;

- thanks to the connecting seam, the external and internal dimensions of the structure remain unchanged;

- simple and cheap way.

The disadvantages of welded joints, as a rule, are due to the low qualifications of the employee. Due to non-observance of technology, rules, inexperience, welding may be incomplete. This means that cracks and displacements can form. Therefore, the welding of radiators must be carried out competently, carefully and carefully.

Requirements for the welder

If you need to replace the heating batteries for gas welding, then it is better to contact a professional welder. The main criterion for choosing a specialist should not be the price for his work, but experience and high qualifications in order to obtain high-quality welding, a sealed and reliable system.

A true professional who replaces batteries in welding should have:

- Certificate confirming qualifications;

- Fire safety ticket;

- Positive characteristics;

- Welding equipment that meets safety standards and regulations.

If the replacement of heating batteries during welding is carried out by a professional, then after installation, the heat transfer will become much higher and more efficient.

What is needed to carry out electric welding?

To weld pipes using electric welding, you need a welding machine. Today, there are two types of such devices: devices made on the basis of a step-down transformer, and inverters that operate at high frequencies. The first type is used extremely rarely, since it is considered morally obsolete. The inverter is a more modern device that is simple and portable. It is possible to adjust the welding mode with high precision. True, in use, inverters are considered less reliable. Therefore, to work with such equipment, you must have a certain qualification.

In addition, heating welding presupposes the presence of other auxiliary equipment:

- special mask with a light filter. It reliably protects eyes and face from sparks and molten metal particles during welding;

- overalls for body protection;

- suede gloves. With their help, the device in the hand will be securely held;

- electrodes;

- metal brush. It is necessary for cleaning the pipe section before welding, for descaling;

- a special hammer that is used to knock down scale.

Battery Replacement: Welding or Threading?

From the very beginning, I would like to say to everyone who is going to change heating radiators - a very correct decision! Bimetallic radiators must be installed in apartments. Read more about the installation of heating radiators

.

Now let's actually talk about welding and carving. Both welding and threading refer to the types of pipe connections and do not in any way affect the quality of heating the radiator, the service life of the radiator itself and the comfortable conditions in the heated room. That is, if the supply pipes are made with high quality and conscientiously, then the radiator will heat well in the first and second cases. However, there are several things to look out for when choosing a mounting method:

1. Appearance.

Compare the threaded radiator and the welded radiator with a pipe bender. Below are a few photos of examples of carving work and our work.Obviously, welding with a pipe bender looks much better than a threaded liner.

The first picture on the thread, the second picture on the welding

Our work on battery replacement can be viewed in Our Gallery

2. Saving the client's time.

To replace the battery on the thread, you need to take measurements, pre-make the eyeliner and come to the installation a second time. Welding work does not require measurements. We will immediately come to work and save you a lot of time. We will do all the calculations directly by phone, select radiators and book you on a convenient date.

3. Reliability of connections.

Weld seams are as strong as a solid pipe, because the connection here is at the molecular level. Welding will last as long as the pipe itself (30-50 years). Unlike the thread, which is a rather capricious connection. The thread is afraid of vibrations and mechanical stress (moving furniture, touching a pipe). From this, it quickly "loosens" and begins to leak. That is why the guarantee for threads is 2-5 times less than for welding!

4. Technical ability to replace any radiator.

Indeed, it often happens, for example, in old houses (over 30-40 years old), heating pipes are in a deplorable state. It is simply impossible to cut threads on these pipes, so in such apartments it is possible to install batteries only for welding. Or, for example, the pipes of the heating riser are located too close to the wall, which also excludes the possibility of working on the threads.

5. It is possible to hide pipes in the walls.

It is highly discouraged to do this on threads. In welding, it is possible to hide pipes in the wall without any problems. The service life of the radiator and piping will not change from this. This is why welding is more expensive than threading.

How to choose the right electrode?

Before starting welding, you need to select an electrode. It should be noted that the electrodes for welding heating pipes may be different. They differ in the thickness of the core, the amount of coating and the method of production. Rod thickness for pipes - 2-5 mm. And the coating can be 3-20% of the total mass.

Depending on the material of manufacture, the electrode can be consumable and non-consumable.

Melting ones are made from welding wire, non-consumable ones - graphite, tungsten and electrical coal.

Main steps

The choice of radiators is very wide: bimetallic, the most popular, aluminum, panel, cast iron. Each type has its own advantages and disadvantages, and the choice depends on the installation site and operating conditions.

Preparation and assembly

Before starting welding work, it is necessary to prepare the room: insulate furniture, close the walls and floor from possible damage. It is necessary to drain the water from the system, remove the heat carrier (in other variations). Next, with the help of a grinder, it is necessary to dismantle the spent radiators

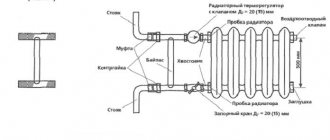

After all the preparatory work, you need to assemble a new battery for installation. For this, the nuts at the joints are sealed with linen, coated with investment paste and tightly wrapped. A special valve for air discharge is installed on top, and an American ball valve with a squeegee is placed on the side of the connection with the pipe.

Installation

The installation of a new battery is carried out on special brackets, after which all connections with pipes are adjusted - they are welded, and then the seams are cleaned. It should be borne in mind that gas welding is usually used to connect pipes not exceeding 100 mm in diameter.

After welding, be sure to check the system for strength and tightness. Replacing radiators with gas welding in comparison with the threaded method is a longer and more expensive process, which has some drawbacks. But quality, reliability and durability are an undeniable and winning advantage.

General information about gas welding technology

The overwhelming majority of experts are sure that replacing heating devices with gas welding makes it possible to create a higher-quality and durable connection. This type of installation creates a weld seam that can withstand a short-term excess of the permissible process pressure in heat supply systems during a water hammer. The installation of heating radiators is entrusted to highly qualified gas welders. First of all, homeowners are interested in this, so as not to leave the apartment without heat energy in winter, and not to flood the house in case of leaks due to a poor-quality welded seam.

Replacement of gas-welded batteries is used to assemble metal units of the heat supply system, regardless of their size and configuration. In the course of gas welding, the edges of the parts to be joined melt, on which a specialized filler material in the form of a wire is deposited for hardening. The operational reliability of the operation is achieved by using welding gases: acetylene and oxygen. One cylinder of each gas will be enough to install 4 heating radiators. The liquid alloy, when cooled, forms a strong and rather strong connection of the elements to be welded. The correct replacement of heating radiators by gas welding lowers the chance of a heating system breakthrough to zero, since the joint, due to the direction of the solder, becomes many times more reliable than the material of the in-house pipelines itself.

Only highly professional gas electric welders with a certificate of education in the above profession are allowed to install heating batteries using gas welding. In addition, they must be in possession of a valid pass-admission for knowledge of the rules of PTB. It is also recommended that the worker has practical experience in gas welding. No less requirements are imposed on welding equipment, it must be certified with a shelf life, in working order and meeting generally accepted safety rules.

Replacement of gas-welding batteries should be carried out exclusively by highly professional gas-electric welders.

Gas welding of heating radiators is carried out by a welder in overalls, in specialized glasses with a shield to protect the eyes.Do not lose sight of the requirement to work with gloves to protect hands from hot molten metal. According to the safety requirements for the uniform of a gas welder, the following protective equipment is included: goggles, an eyecup, heat-resistant gloves and safety shoes.

Currently, in multi-storey buildings, a ban has been imposed on the performance of gas welding in the absence of a special permit from the operating organization responsible for the safe operation of indoor heating systems. Violators of the above legislative norm are threatened with imposing penalties.