A kind of heat insulator

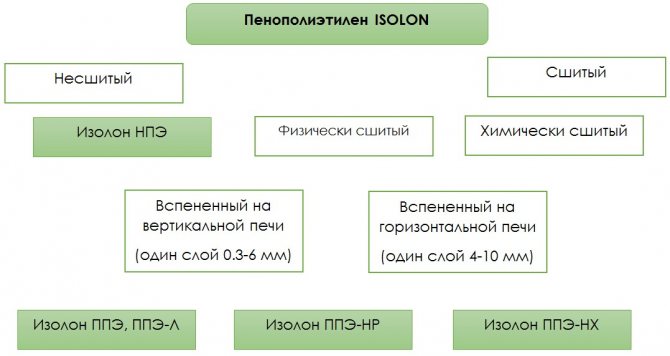

Depending on the manufacturing technology, there are main types of isolon and its varieties.

Insulation can be of two types: stitched and unstitched

... A stitched heat insulator is designated as NPE, an uncrosslinked one is designated as PPE.

Based on the structural features of the filler, the insulation is divided for the following brands:

- PPE-500 and 500L. The basis is polyethylene, cross-linked in a vertical oven

in a physical way. The finished sample has a cross-linked structure. - PPE-500NR. A similar heat insulator, but made in a horizontal oven.

- PPE-500-300. It is produced in a horizontal furnace by foaming the polymer mass with the addition of chemical components.

- 100 and 100L (old name - NPE). Manufactured from extruded polyester.

Depending on the mounting option

, heat insulators are divided into the following types:

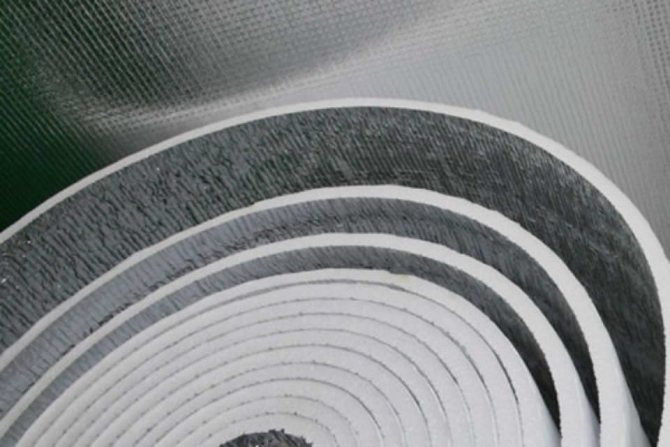

- Rolled. It is produced in rolls, from 50 to 200 meters long, from 0.8 to 1.5 meters wide. The height ranges from 0.2 to 1.0 centimeters.

- Sheet. Produced in slabs. The dimensions of the slabs can be of two types: 1.0x2.0 meters or 1.4x2.0 meters. Isolon is characterized by its thickness, which ranges from 1.5 to 10.0 centimeters.

- Foiled. It can be produced in slabs and rolls. Foiled Izolon can have one or two foil side

... The letter L in the marking means that the foil sides are connected to the insulation by lamination. Available in rolls. Has dimensions: length from 80 to 300 meters, width 1.2 meters. Insulation thickness from 1.0 to 10.0 centimeters. - Tape. An adhesive composition is applied to the surface, protected from drying with a special sticker. Before gluing the insulation, the sticker must be removed and the strip must be pressed in the right place. The adhesive composition can be on one or on both sides of the heat insulator. Available in rolls, 10, 20 or 30 meters long, 1.0 meters wide.

For gluing boards and rolls butt to each other, available special glue.

It can be Quick-Bond, Contact Acrol or Neoprene spray.

Before you start gluing Isolon, you need to familiarize yourself with the recommendations that are indicated on the package with the glue.

Popular isolon manufacturers are Pereslavl-Zalessky "Lit Plant" and Izhevsk Plastics Plant.

Depending on the type and size, its price fluctuates. So, rolled insulation costs from 110 to 500 rubles per square meter. A heat insulator in slabs will cost from 315 to 1015 rubles per square meter.

Installation features

When installing isolon, it is necessary to take into account that when joining the sheets, they must be sealed. When repairing, some people use regular tape, but this is a mistake. To get a solid coating without cold bridges, it is better to use a special tape. Self-adhesive PPE or IzolonTape is similar in its properties to the base material; it also has high elasticity, good ductility, and also has excellent strength, but it has an adhesive layer, which ensures easy installation.

It should be noted that this insulation is a safe and environmentally friendly material. It is safe for human skin, as well as contact with products. There is a peculiarity in some types of isolone - they have a very specific, not very pleasant aroma. But this problem will disappear by itself over time, when the material is ventilated. This moment is connected with the process of creating this building material.Izolon has become widespread due to its low cost, as well as due to its fairly easy installation. The price will depend on the manufacturer, on the thickness and on the type of coating.

Characteristics

Depending on the type of heat insulator, its specifications

may vary slightly. But they remain within the limits of the indicators indicated in the table.

| Parameter | unit of measurement | The quantity |

| Density of the sheet | kg / cubic meter | 25-40 |

| Water absorption | % | Up to 1 |

| Compression strength | MPa | 0.2-0.3 |

| Operating temperature | ° C | -70 to +90 |

| Heat reflection | % | 98 |

| Thermal conductivity | W / mS | 0,031-0,037 |

| Vapor permeability | mg / mhPa | 0,001 |

| Sound attenuation | % | 50-70 |

| Heat capacity | kj | 1.90-1.95 |

| Flammability group | G2, G3, G4 | |

| Toxicity group | T3 |

TRADING SPECIFICATION

Range of products

The table below gives an overview of the existing grades of IZOLONA.

Test work may be necessary depending on the required foam thickness.

| Brand | 05 | 07 | 10 | 15 | 20 | 25 | 30 | 35 |

| Seeming density, kg / m3 | 200 | 140 | 100 | 66 | 50 | 40 | 33 | 29 |

| PPE | X | — | X | X | X | X | X | X |

| PPE FR | — | — | — | — | X | X | X | X |

| PPE NR | X | X | X | X | X | X | X | X |

| PPE NH | X | X | X | X | X | X | X | X |

ISOLON is supplied in rolls and sheets. Linear parameters are shown in the table:

| Brand | Nominal thickness, mm | Thickness tolerance, mm | Width after trimming the edge, mm | Optimal length, m | Tolerance for length,% |

| PPE | |||||

| 0501 | 1,0 | ± 0,10 | 600-1040 | 500 | +5 |

| 0502 | 2,0 | ± 0,20 | 600-1040 | 230 | +5 |

| 0503 | 3,0 | ± 0,30 | 600-1040 | 160 | +5 |

| 1001 | 1,0 | ± 0,10 | 800-1300 | 500 | +5 |

| 1002 | 2,0 | ± 0,20 | 800-1500 | 230 | +5 |

| 1003 | 3,0 | ± 0,30 | 800-1500 | 160 | +5 |

| 1004 | 4,0 | ± 0,40 | 800-1500 | 120 | +5 |

| 1501 | 1,0 | ± 0,10 | 900-1500 | 500 | +5 |

| 1502 | 2,0 | ± 0,20 | 900-1500 | 230 | +5 |

| 1503 | 3,0 | ± 0,30 | 900-1500 | 160 | +5 |

| 1504 | 4,0 | ± 0,40 | 900-1500 | 120 | +5 |

| 2001 | 1,0 | ± 0,10 | 1000-1500 | 500 | +5 |

| 2002 | 2,0 | ± 0,20 | 1000-1500 | 230 | +5 |

| 2003 | 3,0 | ± 0,30 | 1000-1500 | 160 | +5 |

| 2004 | 4,0 | ± 0,40 | 1000-1500 | 120 | +5 |

| 2005 | 5,0 | ± 0,50 | 1000-1500 | 100 | +5 |

| 2502 | 2,0 | ± 0,20 | 1000-1500 | 230 | +5 |

| 2503 | 3,0 | ± 0,30 | 1000-1500 | 160 | +5 |

| 2504 | 4,0 | ± 0,40 | 1000-1500 | 120 | +5 |

| 2505 | 5,0 | ± 0,50 | 1000-1500 | 100 | +5 |

| 3002 | 2,0 | ± 0,20 | 1000-1500 | 230 | +5 |

| 3003 | 3,0 | ± 0,30 | 1000-1500 | 160 | +5 |

| 3004 | 4,0 | ± 0,40 | 1000-1500 | 120 | +5 |

| 3005 | 5,0 | ± 0,50 | 1000-1500 | 100 | +5 |

| 3502 | 2,0 | ± 0,20 | 1000-1500 | 230 | +5 |

| 3503 | 3,0 | ± 0,30 | 1000-1500 | 160 | +5 |

| 3504 | 4,0 | ± 0,40 | 1000-1500 | 120 | +5 |

| 3505 | 5,0 | ± 0,50 | 1000-1500 | 100 | +5 |

| 3506 | 6,0 | ± 0,60 | 1000-1500 | 80 | +5 |

| Brand | Nominal thickness, mm | Thickness tolerance, mm | Cutting width after edge, mm | Optimal length, m | Tolerance for length,% |

| PPE - L | |||||

| 1506 | 6,0 | ± 0,60 | 1000-1500 | 80 | +5 |

| 1508 | 8,0 | ± 0,80 | 1000-1500 | 60 | +5 |

| 1510 | 10,0 | ± 1,00 | 1000-1500 | 50 | +5 |

| 1512 | 12,0 | ± 1,20 | 1000-1500 | 40 | +5 |

| 1515 | 15.0 | ± 1,50 | 1400 | 2 | +5 |

| 1520 | 20.0 | ± 2.00 | 1400 | 2 | +5 |

| 1530 | 30.0 | ± 3.00 | 1400 | 2 | +5 |

| 1540 | 40.0 | ± 4.00 | 1400 | 2 | +5 |

| 1550 | 50.0 | ± 5.00 | 1400 | 2 | +5 |

| 2006 | 6,0 | ± 0,60 | 1000-1500 | 80 | +5 |

| 2008 | 8,0 | ± 0,80 | 1000-1500 -.-, | 60 | +5 |

| 2010 | 10,0 | ±1.00 | 1000-1500 | 50 | +5 |

| 2012 | 12,0 | ± 1,20 | 1000-1500 | 40 | +5 |

| 2015 | 15.0 | ± 1,50 | 1400 | 2 | +5 |

| 2020 | 20,0 | ± 2.00 | 1400 | 2 | +5 |

| 2030 | 30.0 | ± 3.00 | 1400 | 2 | +5 |

| 2040 | 40.0 | ± 4.00 | 1400 | 2 | +5 |

| 2050 | 50.0 | ± 5.00 | 1400 | 2 | +5 |

| 2506 | 6,0 | ± 0,60 | 1000-1500 | 80 | +5 |

| 2508 | 8,0 | ± 0,80 | 1000-1500 | 60 | +5 |

| 2510 | 10,0 | ± 1,00 | 1000-1500 | 5O | +5 |

| 2512 | 12,0 | ± 1,20 | 1000-1500 | 40 | +5 |

| 3006 | 6,0 | ± 0,60 | 1000-1500 | 80 | +5 |

| 3008 | 8,0 | ± 0,80 | 1000-1500 | 60 | +5 |

| 3010 | 10,0 | ± 1,00 | 1000-1500 | 50 | +5 |

| 3012 | 12,0 | ± 1,20 | 1000-1500 | 40 | +5 |

| 3015 | 15,0 | ± 1,50 | 1000-1500 | 2 | +5 |

| 3020 | 20,0 | ± 2,00 | 1000-1500 | 2 | +5 |

| 3030 | 30.0 | ± 3.00 | 1000-1500 | 2 | +5 |

| 3040 | 40,0 | ± 4.00 | 1000-1450 | 2 | +5 |

| 3050 | 50.0 | ± 5.00 | 1000-1450 | 2 | +5 |

| 3506 | 6,0 | ± 0,60 | 1000-1500 | 80 | +5 |

| 3508 | 8,0 | ± 0,80 | 1000-1500 | 60 | +5 |

| 3510 | 10,0 | ± 1,00 | 1000-1500 | 50 | +5 |

The optimal roll length is calculated taking into account the optimal roll diameter for loading vehicles. At the request of the customer, the length of the roll can be longer than the optimal one.

As a standard, ISOLON is supplied without trimming. On request, we can produce trimmed material.

Width tolerances:

Without trimming - ± 50 mm;

With trimming - ± 5 mm.

Other lengths, widths and thicknesses can be agreed with the customer (fixed in a separate specification).

ISOLON is supplied in rolls (up to 12 mm thick) or in sheets (12 to 50 mm thick).

IZOLON rolls are wound on cardboard spools with a diameter of 78 or 152 mm.

Due to the continuous foaming process, there may be joints in the roll. The number of joints depends on the length of the roll. The minimum distance between two joints or the end / beginning of the roll and the joint is 10 m.

| Isolone length, m | Number of joints | |

| Single layer isolon | Multilayer isolon | |

| Up to 50 inclusive | 0 | 1 |

| Over 50 to 100 | 1 | 2 |

| - 100 to 150 | 2 | 4 |

| - 150 to 200 | 3 | 6 |

| Standard color | White gray |

| Coloring (extra charge) | Silver gray |

| Dark grey | |

| The black | |

| Yellow | |

| Red | |

| Blue | |

| Green | |

| Purple | |

| Orange | |

| Khaki | |

| Other colors | By agreement with the customer, it is possible to manufacture ISOLON of various colors (this may require experimental work) |

Slight color differences are allowed within a roll, as well as between batches. Prolonged exposure of the product to ultraviolet radiation may cause discoloration. In production, only cadmium-free dyes are used, as well as dyes approved for contact with food.

Below are the density indicators of ISOLON PPE, PPE NR, PPE NKh and PSEV with tolerances:

| Brand | 05 | 07 | 10 | 15 | 20 | 25 | 30 | 35 |

| A type | ||||||||

| PPE (kg / m3) | 200±20 | 150±15 | 100±10 | 66±6 | 50+5 | 40+4 | 33±3.3 | 29±2.9 |

| PPE NR (kg / m3) | 200±30 | 150±15 | 100+10 | 66±8 | 50+8 | 40+6 | 33±5 | 28+4 |

| PPE НХ (kg / m3) | 200±30 | 150±15 | 100±10 | 66±8 | 50±8 | 40+6 | 33±5 | 28+4 |

Please be aware that this specification is indicative only. Batch tolerances are negotiated in a separate specification for each order.

In the process of foaming on the surface of ISOLON, the formation of cavities and bubbles with a diameter of not more than 2.5 mm and a depth within the thickness tolerance is allowed, in an amount of not more than 3 pieces per 1 dm2. If the indicators are critical, ask for control samples.

IZOLON possesses remarkable stability of parameters at elevated temperatures. However, ISOLON is a thermoplastic material, as a result of which linear shrinkage of dimensions appears.

The upper working temperature at no load is the temperature at which the linear shrinkage along the length and width (x, y - direction) after storage in a ventilated oven for 24 hours does not exceed 5% (preliminary foam temperature 23 ° C).

For various types of IZOLON, this temperature is:

Type Temperature ° C

PPE, PPE NR, PPE NH 100

PSEV 80

IPE 80

Under short-term high-temperature loads (for example, during thermoforming), the specified linear shrinkage can be greater.

Izolon with an index of FR or Cl. 1 is produced with the addition of fire retardants and is classified as a low-combustible material. The concentration of fire-extinguishing additives can be different in accordance with the customer's requirements for the flammability of ISOLON.

| without the addition of a flame retardant | with the addition of a flame retardant | |

| thickness, mm | 1-15 20-50 | 1-15 20-50 |

| flammability group according to GOST 30244 | G2 G4 | G2 G2 |

| flammability group according to GOST 30402 | B2 B2 | B2 B2 |

| smoke generating capacity group GOST 21.1.044 | DZ DZ | DZ DZ |

ISOLON can be supplied with a corona discharge surface treatment when the customer requires increased surface wettability for subsequent processing (for example, for printing, adhesive coating, etc.). In this case, the maximum thickness of the processed sheet is 4 mm.

The type of processing (one- or two-sided) is indicated on the label of each roll. In the case of one-sided processing, the roll is wound inward with the treated surface.

Advantages and disadvantages

The thermal insulation properties of a thermal insulator are complemented by many of its advantages. The main ones are:

- Low thermal conductivity. With a high level of heat retention, it is not recommended to use ordinary isolon as an independent insulation. With high efficiency you can use Isolon foil

. - Good sound absorption. Its sound-reducing characteristics allow it to be used as a sound insulator capable of damping a sound wave.

- Resistant to chemical and antiseptic agents. Izolon has a composition that resists corrosion and decay.

It is not affected by mold and fungal diseases. Withstands contact with antiseptics and many chemical compounds. - High fire resistance. The heat insulator belongs to the class of moderately flammable and moderately flammable materials. The insulation burns strongly or not depends on the strength of the fire effect. But the material ignites very badly and cannot be a source of fire. In case of fire, it emits a lot poisonous smoke.

- Environmental Safety. The heat insulator is made of environmentally friendly materials. Does not emit substances harmful to humans and the environment.

- Considerable strength. The heat insulator can break under mechanical stress or puncture, but has good compressive strength. To avoid accidental rupture of the surface, it is sufficient to install decorative cladding.

- Low vapor permeability. The heat insulator has technical characteristics that do not allow air to pass through. If it is necessary to equip a room with high humidity with material, it is necessary to consider the installation of a ventilation system.

Lack of hygroscopicity. Due to its water-repellent properties, the material will be used as a waterproofing agent. When installing a roof, the material may protrude insulation and waterproofing

at the same time.- Ease of use. The material is flexible and elastic, has a low weight. It can be easily cut with a construction knife or scissors and installed by yourself.

- Long period of operation. After installation, the material can serve about 90 years old.

- Reusable. The heat insulator can be dismantled and installed in a different place. At the same time, the isolon retains its properties and characteristics, and the material restores its shape after the termination of mechanical efforts.

- Significant savings. When using the material for thermal insulation of the room, saving on heat loss is 35-40%

.

Along with numerous positive qualities, there are some cons

... They are as follows:

- Do not apply wallpaper or plaster to the insulation.

- The aluminum coating can easily break with minor mechanical stress.

- The heat insulator has high cost

.

Izolon PPE: properties, advantages and scope of the material

Insulation is made in the form of sheets, which are rolled into a roll. The material is lightweight, while being an excellent sound insulator. Izolon has almost no drawbacks, which determines its wide popularity among consumers. Such features make it possible to use the material for making interfloor ceilings, for isolating walls from shocks and sounds. Once again, it is worth mentioning the complete hygienic safety of the material. With the help of izolon, you can almost completely get rid of heat leakage.

Folgoizol is used in many areas of human activity, including medicine, utilities and agriculture, construction, trade, automobile and shipbuilding. Insulating the surfaces of walls, floors, roofs in buildings, structures, devices, units with a polymer reflective material makes it possible to create a shock-absorbing substrate, reduce dynamic loads, and protect against negative environmental factors.

Please note: the correct use of foil-insol makes it possible to eliminate shallow defects on the floor surface. Foil isolon is excellent for sealing ceilings, joints, seams, and places of passage of communication networks through walls. Warming of premises using a polymer canvas is characterized by minimal costs. Thermal insulation with foil insulation 10 mm thick makes it possible to obtain a heat saving effect similar to the results from a 5 cm layer of wood or brickwork 15 cm wide.

This property of the material determines its widespread use for insulating baths, saunas, swimming pools and other buildings with high humidity. Laying a reflective polymer sheet with an adhesive base on the floors and during the installation of underfloor heating allows you to increase heat transfer, which in turn reduces energy consumption for heating, which cannot be said about PP-film. Folgoizol is also needed for the production of elements of tourist and sports equipment, rugs, life jackets, cameras to create a stable temperature regime.

The active use of heat-insulating material in many areas of modern man's activity confirms its indispensability. The use of foil-insol is considered a rational, cost-effective solution that allows you to combine the excellent performance characteristics of a porous polymer sheet covered with aluminum foil, with the cost of the effect of heat saving and the time spent on its installation.

The first is a sewn insulation with closed cells, the second is an unstitched gas-filled analogue. There is no big difference in terms of thermal insulation capabilities between the materials. NPE is suitable for organizing refrigeration equipment and other structures exposed to low temperatures.

PPE is denser and thicker, thickness from 1 to 50 mm, moisture resistant material. NPE is thinner and more flexible 1-16 mm, but slightly inferior in terms of moisture absorption. Material release form - washed and rolls.

The thickness of the material varies from 3.5 to 20 mm. The length of the rolls ranges from 10 to 30 m with a width of 0.6–1.2 m. Depending on the length and width of the roll, it can hold from 6 to 36 m2 of material. The standard sizes of mats are 1x1 m, 1x2 m and 2x1.4 m. No modern material is widely used if it does not have the necessary number of positive aspects of use - at least it should be better than its predecessors or fellows for the intended purpose.

This turned out to be a foil isolon, among the advantages of which the following factors can be noted. This is a relatively inexpensive insulation - not polystyrene with its cheapness, but also not mineral wool, with all its auxiliary materials in the form of vapor barriers, frames, and so on.

Naturally, the isolon is not without its drawbacks - among the few disadvantages of this type of insulation, one can note the abundance of smoke when this material burns. In principle, in itself, it is a hardly flammable insulation and starts the combustion process only at high temperatures. This nuance can not be taken into account at all. Also, despite its vapor permeability, which in fact only polyethylene foam possesses, this material, if installed incorrectly, can create the effect of a thermos - some people do not like this.

By the way, this quality of the material is used in the process of manufacturing thermal bags, containers for transporting medicines and other things, where it is important to maintain a stable temperature for a long time.

And finally, a few words about how to choose a foil isolon, and in particular, how to determine the required thickness of the material. It is important to take into account not only the required degree of thermal insulation, but also the specifics of the material itself, there are some limitations. For example, it is more expedient to lay an isolon under the screed with a thickness of 5 to 30 mm.

Using the material as a substrate under the laminate, you should not use an isolon thicker than 4mm. Foil insulation with a thickness of 10 mm or more is used for thermal insulation. Well, if we are talking only about noise reduction, then it makes no sense to use foil isolon thicker than 10 mm.

These are the features of this insulation, and it takes quite a long time to be introduced into the details, explaining why it is this way and not otherwise - partly the density of the foamed polyethylene and partly its physicochemical qualities are to blame.

In conclusion, the topic about foil-clad isolon, I will add only one thing - when purchasing this material for the needs of sound insulation insulation, keep in mind that a special foil tape is used to connect it. Naturally, no one will forbid you to use ordinary adhesive tape, but in the case of it, the effectiveness of insulation is slightly reduced. If we talk about the construction industry, then this thermal insulation material is optimal for finishing balconies, roofs, external and internal walls of the roof.

It is suitable for any surfaces, including for thermal insulation of a wooden house, as it provides vapor permeability of the walls, which prevents wood from rotting. At the next stage of work, you need to lay the first layer of thermal insulation. To do this, the isolon is cut to size and placed over the thermal insulation. In this case, there should be no gaps between the pieces of material. At the joints, glue the pieces of material with tape.

If you decide to do with one layer of thermal insulation, then in the future you need to lay another layer of waterproofing on top of the isolon and start installing the finished floor.

If the floor must have several layers of thermal insulation, then after the first installation, beams must be installed. To do this, the timber previously treated with antiseptic impregnation is cut into the required number of elements for work and placed above the insulation.

Place the lags along the edges near the walls themselves. During installation, constantly check the evenness of the position of the lags with a level. Having eliminated the differences, fix the elements with self-tapping screws or dowels. Each lag must be fixed by at least 4 identical fasteners. After that, a heater is placed in the space between the pieces of the beams, and an isolon is placed on top of it. In this case, the insulator should be installed with the foil down so that it completely covers the space between the lags.

At this stage, also lay the material as tightly as possible, without the slightest gaps. At the end of the work, the finishing floor will remain on top of the second layer of insulator.

Izolon is a foamed polyethylene backed up with various materials with aluminum foil, polymer film, and fabric. The thickness of the coating itself can be from 3 to 10 mm, it is used in various insulating technologies. Depending on the production method, two brands can be distinguished - Izolon PPE polyethylene foam, which is physically sewn and foamed using a special technology, as a result of which it does not contain freon and Izolon NPE is gas-filled material, foamed with butane, produced by extrusion.

The first brand significantly surpasses the second in terms of durability and ease of use, the surface is smooth, the elements are precisely adjusted. In both cases, Izolon is foil-clad, this is its most commonly used option in construction. Izolon's installation methods may differ depending on which part of the building is being insulated, but the installation process itself is relatively simple.

At the same time, wall insulation with Izolon will be more effective if an air gap is created between the insulator and the wall. Alternatively, small slats can be stuffed onto the wall, onto which the material is then attached. Since the insulator is supplied in rolls, it is better to calculate all the required dimensions in advance. Izolon's price depends quite strongly on the type of material. The average price of a self-adhesive Izolon is from rubles. The price of Izolon 10 mm thick of the same variety will be already rubles.

The price of self-adhesive foil isolon starts from rubles. Buy Izolon 10 mm maximum thickness is also available in a self-adhesive version. Reviews of Izolon as a building insulation are generally positive, if all the technologies for laying other materials were followed in full.

Foil isolon effectively resists heat radiation from the walls, creating a barrier to warm air. The material consists of air bubbles that do not retain heat. Izolon is an environmentally friendly and safe material. Izolon material is used wherever it is necessary to insulate, insulate, reduce the noise level, level the surface of the walls or floor, insulate from moisture. Foil isolon is used in various industries. The material is used for the inner lining of cars, which prevents heat loss and creates sound insulation.

In construction, the material is used for thermal and noise protection. The material is widely used for packaging to protect fragile materials. Due to its universal characteristics, izolon is used in domestic conditions. You can make a multi-layer structure. To do this, it is necessary to attach the initial isolon layer to the wall so that the foil is outside.

The second layer is fox foam or cotton wool. The third layer must be fixed so that the foil is also outside. On top of the three layers, you can attach slats to which drywall sheets are screwed. This heat-insulating product is made of foamed polyethylene laminated on one or several sides with a metallized polypropylene film. The material can also consist of polyethylene laminated with polished aluminum foil.

Scope of use

The heat insulator has found application in many industries and agriculture. It is mainly used in the construction of buildings and structures. It is applied to perform following works:

- Thermal insulation of concrete and cement floors, walls, roofs, floors.

- Equipment for foundations, basements and underground premises.

- Thermal insulation of secondary, ancillary, residential and non-residential

premises. - Equipment for trunk and communication pipelines.

- Compensating, shock-resistant lining of sports equipment and surfaces.

- Soundproof lining on all types of buildings and structures.

- Steam and thermal protection of buildings with high air humidity.

- Insulation of ventilation shafts, gas and water pipelines, other engineering systems.

- Protection of household appliances and refrigeration equipment, vehicles of all types.

- Heat, steam and moisture protection of commercial and warehouse buildings.

- Manufacturing of special clothes and shoes.

Examples of using isolon in construction:

| Application area. | Description. |

| Thermal insulation of wall partitions and external walls of buildings. | Insulating layer of isolon between and internal panels of private houses, outbuildings, garages, basements, balconies, etc. |

| Impact sound insulation of floors (floating floors) | Isolon sheets are used as acoustic and thermal insulation partitions between concrete floors and the floor. |

| Substrate under parquet, laminate board and various floor coverings. | Izolon sheets to provide shock-sound and thermal insulation and as a barrier when water vapor rises (Izolon NPE brand is recommended) |

| Litter for artificial turf. | Isolon sheets as shock-absorbing underlays for artificial turf. |

| Sealant for slate, tiles. | Isolon profile used as a seal for slate or other corrugated surface for thermal insulation, protection against dust penetration, prevention of moisture condensation and noise reduction. |

| Compensation pillows. | Isolon mats used to compensate for linear elongations during underground laying of hot and cold water pipelines without a channel. |

| Insulation of tunnels. | Isolon sheets for thermal insulation, as well as to prevent the penetration of groundwater with the subsequent formation of ice layers. |

| Sheets for curing concrete. | Sheets preventing heat loss during hydration during concrete laying at low temperatures. |

| Pipe insulation. | Isolon strips for thermal insulation (reflective insulation) of pipes for hot and cold water supply. |

| Insulation of ventilation pipes. | Isolon sheets or flooring for thermal and sound insulation of air conditioning units. |

| Concrete pavement joints. | Sheets or decking between concrete blocks to reduce stress and prevent cracking. |

| "Floating" stairs. | Sheets for impact insulation from the floor and side walls. |

| Sealing tapes. | Sealing joints of prefabricated elements of buildings and structures. Primary seal for expanding joints or non-bonding backing for cold air seals. |

| Slip diaphragm | Isolone strip as a partition between lightweight concrete structures. |

| Window insulation tape. | Isolon tape as a sealing joint between glass and frame. |

| Tape for plasterboard profiles | Isolon tape with a self-adhesive layer forms a sound-insulating sealing layer between the building structures and the guide profiles of the plasterboard partitions. |

The given list of fields of application of IZOLON is incomplete and serves only as a basis for new ideas.

Insulation tools and materials

Carrying out work on the insulation of the building requires a certain material and tools.

The list of materials includes:

- Izolon.

- Mineral wool.

- Plywood sheets.

- Drywall sheets.

- Flooring.

- Metallized tape and glue.

- Wooden bars.

- Ceiling suspensions.

From tools

to complete the work you will need:

- Hammer.

- Screwdriver or screwdrivers.

- Construction knife.

- Construction stapler.

- Galvanized nails and screws.

- Measuring tool.

What is Isolon?

Izolon is a polyethylene foam, the structure of which consists of closed cells. This insulation has a high elasticity and has excellent thermal insulation properties.At the moment, it is one of the most effective materials for insulating various premises.

It has become widespread in areas such as mechanical engineering and the automotive industry. It is also used in the shoe industry, the production of refrigeration and climatic equipment.

Insulation of the floor with isolon

Floor insulation can be done in two ways. Let's consider both options. The first method involves the presence of a second insulation and waterproofing agent. It is of higher quality, but the cost of such a floor will be somewhat more expensive. The first option provides performance of the following works:

- The sub floor must be cleaned of dust and dirt, covered with a waterproofing film. The strips of the film are laid overlapping with the overlap of one strip over another by 8-10 cm. The joining place of the strips is closed construction tape.

- Using corners and dowels, it is necessary to install the bars on the floor. It is recommended to make the bars with a height equal to the thickness of the mineral wool slab. The distance between the blocks should be 3-5 cm less than the width of the mineral wool slab. In this case, the mineral wool slab will fit snugly against the walls of the bar and cover the entire laying area.

- On top of the blocks with mineral wool, it is necessary to lay insulation isolon. The seams of the heat insulator are glued with metallized tape. Laying should be done with the foil side inside the room.

The heat from the room will be reflected from the foil and the thermal conductivity of the laid isolon will be minimal. It is recommended to fasten the insulation to the rails with galvanized nails. - A row of rails must be installed on top, perpendicular to the bottom row. The slats should be between 3-5 cm in height. This will create the necessary ventilation space under the floor. The installation spacing of the slats is recommended from 40 to 60 cm, depending on the width of the floorboard.

- Plywood sheets are laid on the slats. Fastening is carried out to the rails using galvanized nails or screws.

- The floor covering is laid on top of the plywood. It can be a board, laminate, parquet.

The second method does not require a second insulation and waterproofing agent. It includes the following works:

- Wooden floor covering is necessary clean from dust and dirt

. - Lay the material in one layer over the entire floor area. The seams of the heat insulator are glued with metallized tape. Laying should be done with the foil side inside the room.

- Lay plywood sheets on the insulation. Fastening of sheets is carried out through the insulation to the floor using galvanized nails or self-tapping screws.

- The floor covering is laid on top of the plywood.

Insulation of walls with isolon

Thermal insulation of walls is carried out according to the same options and according to the same principle as floor insulation.

So that the sheets of material do not fall and do not create discomfort at work, they are laid on the bottom-up principle. For fastening mineral wool, on the rails are installed ceiling hangers

... They are sold in a hardware store and hold the mineral filler well. If desired, you can use special glue. Isolon pre-fastening can be carried out using

construction stapler.

Note!

For finishing and decorative work, plywood sheets can be replaced with drywall sheets.

Dignity

Izolon is a versatile material with a wide range of applications. It has a number of advantages:

- Excellent insulating properties. Due to its low coefficient of thermal conductivity, it is widely used as insulation for rooms. As a result, it is possible to maintain the required temperature in buildings, which is important in winter. The texture of the izolon PPE is a closed, physically stitched cell, this allows you to achieve the effect of hydro and noise insulation. The material is unable to absorb moisture and interact with other substances.It largely protects surfaces from steam and moisture, and also retains its properties when exposed to oil, gas and other fuels and lubricants. Significantly reduces the noise level, which is very convenient when decorating living quarters and individual elements of car interiors;

- Durability. Long service life, good elasticity are also the undoubted advantages of this material;

- Easy installation. Working with isolon is quite simple, for this it is not at all necessary to have special skills;

- Hypoallergenic and environmentally friendly. It does not cause allergic reactions when it comes into contact with the skin. Izolon does not emit toxic substances and is not capable of causing harm to the environment, human health and his pets. The decomposition products of combustion are carbon dioxide and steam.