Combined gas-wood boilers are, first of all, solid fuel boilers with only a slightly modified design, into which you can install a gas burner that burns natural or liquefied gas. The burner is replaced quite quickly, on its own, according to the manufacturer's instructions, therefore combined boilers are multifunctional and, despite various opinions, retain the reliability and durability of simple solid fuel and gas models.

Despite all the advantages, we do not recommend considering combined models (with the exception of a few cases), since buying a separate gas boiler and a solid fuel boiler will be much cheaper, and the disadvantages of a dual-fuel design are often significant. Let's analyze everything in order.

What are combined gas-firewood boilers?

Mixed-type boilers operating on solid fuel and gas are always a floor-standing design, in size corresponding to conventional solid fuel models. Without using a gas burner, these are ordinary solid fuel boilers that burn not only firewood, but also coal, pellets, peat, anthracite. The piping, installation and connection of universal boilers is carried out in the same way as for single-fuel boilers.

What are they for and how they are used

As we have already said, without special conditions, the purchase of a gas-solid fuel boiler is not justified either economically or practically.

At first, the total cost of separately purchased gas and solid fuel boilers is 90% lower than the combined model. The cost of gas-firewood boilers is 19,000-35,000 rubles and a gas burner is not included in this amount: it must be purchased separately. Only in rare cases are there ready-made assemblies already with a gas burner in the kit. The cost of the burner is on average 6-12 thousand rubles.

The most economical of budget simple boilers for heating a private house

Secondly, the efficiency and functionality of individual single-fuel models are almost always higher than combined ones. The usual design of a solid fuel boiler does not show the highest efficiency (at best, up to 85%) when burning natural or liquefied (balloon) gas, when even budget gas boilers have an efficiency of 88-92%. And this is, accordingly, a lower consumption with the same heat transfer. Also, combined gas-wood boilers are devoid of any functional automation, which is found even on budget gas models.

Thirdly, a small bonus of two single-fuel boilers is that if one breaks down, the second can be used as a backup.

However, there are cases when buying a universal boiler that runs on gas and wood may be more profitable. For instance:

- with access to any type of solid fuel for a symbolic price. When the reserves of solid fuel are exhausted, stable combustion will be required without human intervention, or a previously absent gas main will be installed near the house, you can always switch to a gas burner;

- if the area of the house is rather small and allocate at least 8 sq. m. area for separate single-fuel boilers is impossible.

Device and principle of operation

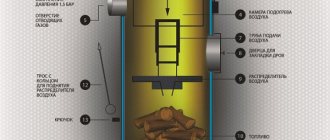

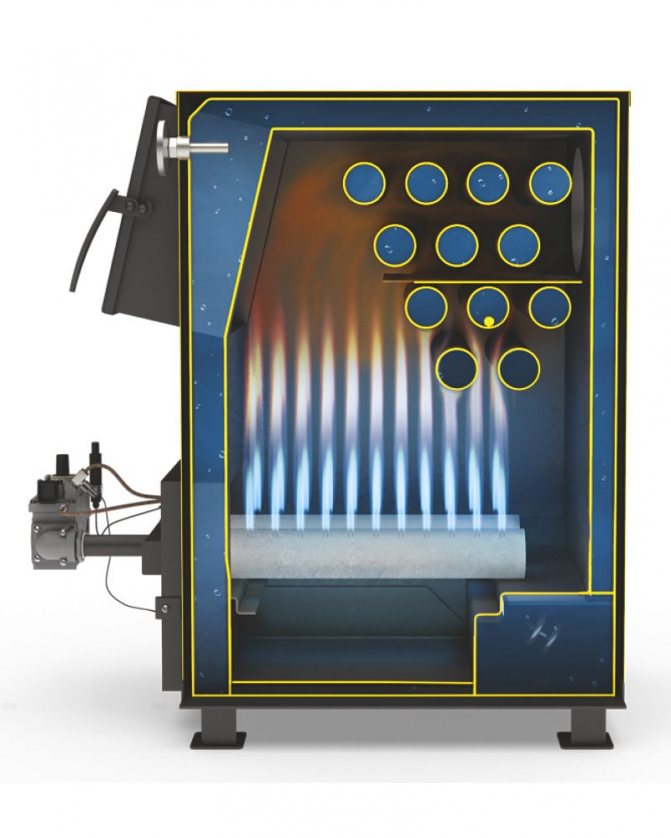

Combined model with installed gas burner. Schematic example of the Teplodar Kupper OK 15 model.

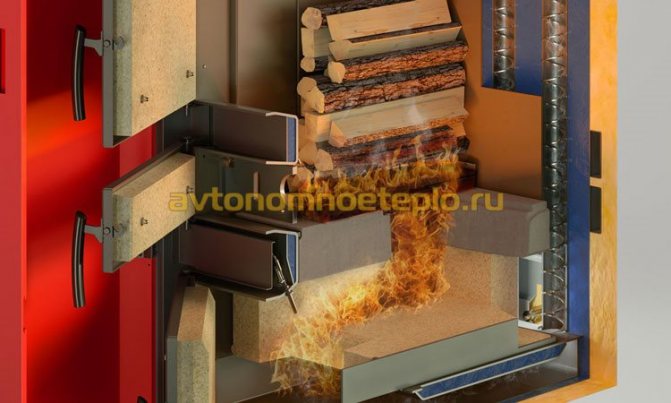

The design of such boilers is traditional: solid fuel is burned in the combustion chamber, the walls of the chamber are a heat exchanger, inside of which the coolant circulating through the system.Fuel loading takes place through the front door, ash is collected in the ash box from below.

If you need to switch to gas, a gas burner with a corresponding mount (without welding) is installed on the ash pan door or a specially designated mount. However, the design of the heat exchanger, designed for a large volume of the combustion chamber, accumulates much less thermal energy when burning gas, the efficiency remains only within 75-85%, as when burning high-quality solid fuel.

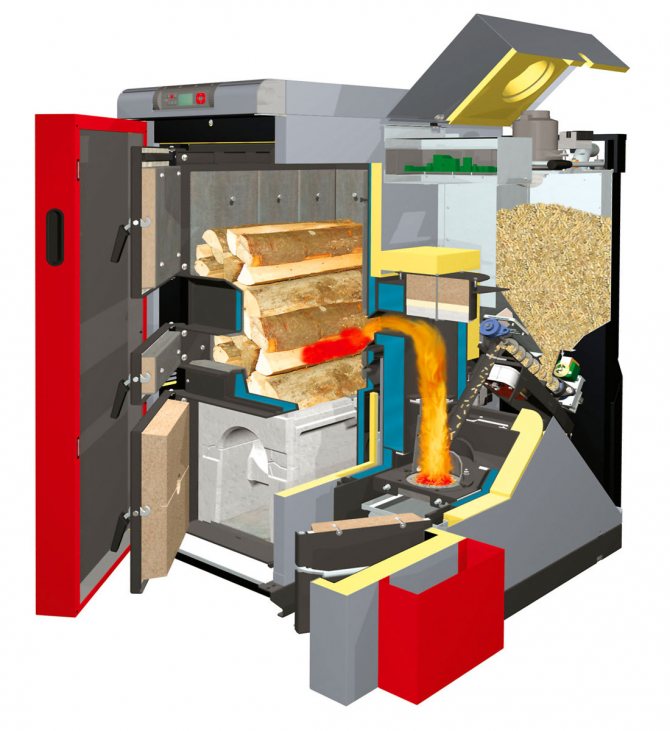

There are also high-tech hybrid models on the market with 2 furnaces, in which fuel can be burned simultaneously. In the upper combustion chamber, solid fuel is usually burned, a gas burner is installed in the lower combustion chamber, separating the combustion chambers by a compact ash box and a heat exchanger design. However, the cost of such models is in the range of 200-350 thousand rubles.

Two-fuel model.

Boilers with a burning time of one fuel tab up to 7 days

Features of gas-fired boilers for home

First of all, it is worth noting that in most cases they take the gas main for the main fuel, and switch to wood heating in case of shutdown for periods of maintenance or accidents. Of course, for a completely universal approach, it is worth installing a combined firewood-gas-electricity device, but not everyone can be satisfied with the cost of electricity.

In general, combined boilers can be fired with different solid fuels, with almost no changes in its design. So, firewood, coal, briquettes, pellets - everything is at the same level in terms of prevalence, the choice depends on the price of various species in a particular region. That is why gas-wood boilers are popular, solid fuel can be easily replaced with an analogue.

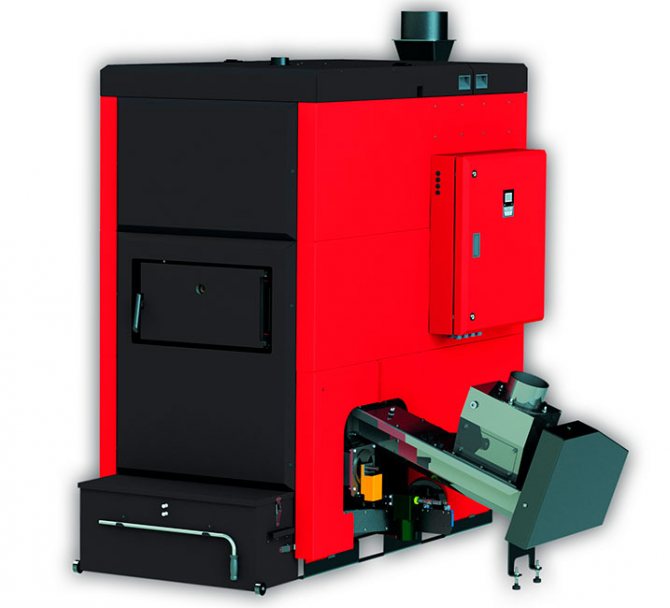

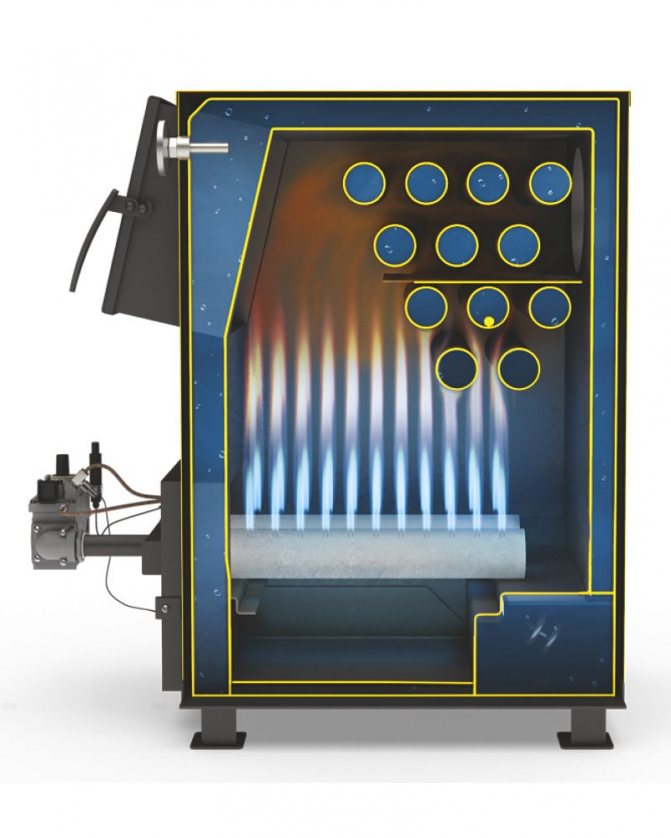

Fig. 2 External view of a gas-fired boiler

Secondly, it is important to consider that solid fuel heating boilers are made of steel and cast iron, which makes them resistant to constant high temperatures during the heating season. This is especially important if coal is used as fuel, which gives a noticeably higher temperature in the furnace.

But it also adds to the hassle. The heavy weight of the equipment in some cases requires reinforcement of the floor covering in the room in the house allocated for its installation. Cast iron boilers for heating gas-firewood are required without fail. Gas-water modifications made of light grades of metal can be mounted on a regular floor, in place of the previously occupied wood or coal stove. Firewood-gas-electricity appliances are usually lightweight.

There are two more types of combined models: single-circuit (they work only to heat the heating system) and double-circuit (the second circuit heats water for the water supply system in the house). So, the gas-wood device can be used as a boiler even in the warm season. The same applies to the wood-gas-electricity appliance.

It is also worth noting this feature. In addition to the removal of smoke through the chimney, when burning with solid fuels, there are solid combustion products that settle in the pallet and require periodic disposal.

The most interesting for heating boilers are universal gas-wood-pellets, which have the possibility of autonomous operation without human intervention for a long time. Such a heater, instead of wood or gas, is capable of working with special pellets. Such a combined option eliminates the need to stock up on firewood, because pellets are usually always available for sale. Alternatively, a combined boiler is still convenient.

Reviews of universal boilers for solid fuel and gas: advantages and disadvantages

| Benefits | disadvantages |

| Significant space savings, which is especially important for small houses with an area of 40-80 m2.The dimensions of the combined models do not differ from the single-fuel ones | Primitive automation or its complete absence (mechanical draft regulator) |

| Availability of single-circuit and double-circuit models | In more than 95% of cases, a gas burner is not sold as a set with a boiler |

| Almost all models are non-volatile (do not require connection to the mains) | Owners often note a rather high noise level of the burners, which cannot be compared with standard burners of gas boilers. |

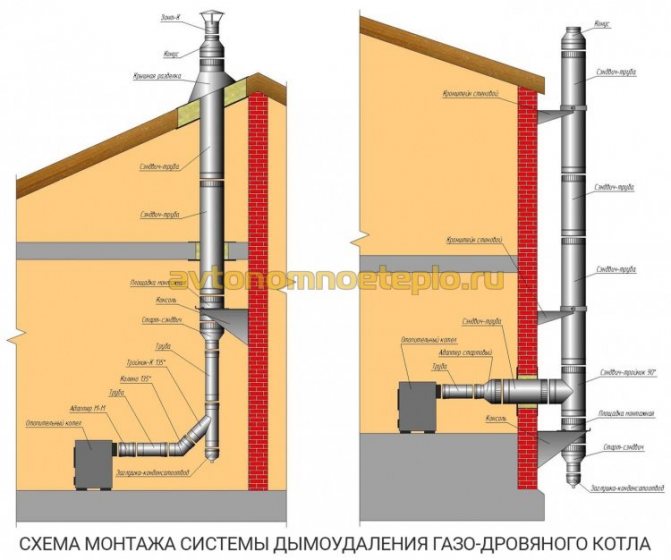

| In combined models, durable cast-iron heat exchangers are often used, when in budget solid fuel and gas almost always - steel vulnerable to corrosion | Higher requirements for chimney draft, which complicates calculations. If the design is wrong, the thrust may not be enough for full gas combustion. |

| A small selection of multi-fuel combined models, especially foreign ones |

Comparison

The main difference between natural gas and liquefied gas (if we consider both in the narrow sense) is, first of all, in the fact that the first is in a gaseous state - with a temperature approximately corresponding to that of the environment, has a minimum pressure and is methane. The second can be a very strongly cooled liquid (if it is liquefied methane), compressed to a liquid state with a gas with different chemical properties (if it is propane and butane), or a substance converted into a liquid through strong compression (if we are talking about compressed gas extracted from the bowels land). Hence the difference in the methods of gas transportation, in the methods of its storage.

Conventional natural gas, as a rule, does not require additional processing before being delivered directly to the consumer - it is enough to ensure that it enters the pipe and then distribute the fuel. Liquefied gas, before being supplied to consumers, must be regasified or removed from the cylinder, turning it from a liquid into a standard state.

Having determined what is the difference between natural and liquefied gas, we will fix the conclusions in the table.

How to choose a combined boiler unit

The selection criteria are practically the same as when choosing a TT model. Be sure to decide on:

- Number of contours... Single-circuit models are more common; they only heat the heating circuit. Dual-circuit models are also capable of heating sanitary water (it does not mix with service water from the heating circuit). Double-circuit models are 10-40% more expensive, but this is still the cheapest way to organize hot water supply in a house.

- Burned fuel... Basically, combined boilers are designed to burn both coal and charcoal, firewood, pellets, peat. Models with a cast iron heat exchanger are capable of burning anthracite. But some boilers are only designed for firewood. The types of fuel are always described in the technical characteristics or the boiler passport.

- Heat exchanger material... There are two options: steel or cast iron. Steel heat exchangers are inexpensive to manufacture, lightweight, resistant to temperature extremes and mechanical damage, but have thin walls and are not resistant to corrosion, their service life is on average 12-15 years. Cast iron heat exchangers are heavy, have thick walls, do not corrode and last more than 30 years, but are used in more expensive models.

- Working pressure... Some models are designed for a working pressure in the system not exceeding 1 bar, which means that they cannot be used in closed heating systems with forced circulation, where the working pressure is usually 1.5-2 bar.

- Efficiency... Not the most informative indicator when burning solid fuel, since it strongly depends on its quality (dryness and type of wood, ash content and calorific value of coal). However, when using a gas burner, 4-5% efficiency can recoup the higher cost in one heating season. The optimal efficiency factor is 80% or more.

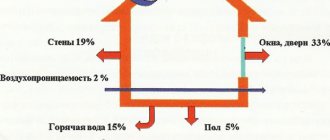

Minimum required power

For an average non-insulated or slightly insulated house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m2. We also recommend setting a power reserve of 20-30%.

For example, for the above-described average house with an area of 100 m2, the minimum required power of heating equipment is 100/10 * 1.3 (30% of the stock) = 13 kW. Boilers of this capacity are not found on the market, so we round up to the nearest higher value - 14 or 15 kW.

Also, when buying a double-circuit boiler, it is recommended to add another 10-15% to the result, since when hot water is heated, the heating circuit is not heated. Total 13 kW * 1.1 (10% stock) = 14.3 kW. If the house is located in the extreme southern or northern point of the country, it is well insulated, has high ceilings or a large glazing area, correction factors are taken into account, which change the result by 5-30% up or down.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

The answer is simple: you need to install a multi-boiler

What is combi boiler firewood electricity gas? Looking at a gas stove for cooking, it is difficult to imagine how a wood stove, a burner and a spiral heater can be placed in one burner. Indeed, it is impossible. However, it is possible to combine different heaters in the same housing.

After installing such equipment in the kitchen, the dependence on the energy carrier is reduced.

And if you have a universal boiler for home heating?

For example, you are connected to natural gas and use it to heat your house. Then, on occasion, you managed to collect a mountain of dead wood in the nearest forest (fortunately, the law on free procurement of such firewood already exists). You may well not waste gas for some time, and heat with wood from the forest (again, practically free).

Or there is an accident on the gas main for several days, and you have no firewood. If the problem occurs during severe frosts, it is a disaster. Here the ability to turn on the electric heating element will come in handy. Yes, it will be expensive, but at least you will not freeze.

That is, the advantages of a heating system capable of operating on different types of fuel are obvious. You can immediately buy a ready-made boiler with wood and electricity, and then retrofit it with a gas burner: such systems are quite common. In general, it turns out to be somewhat more expensive, but you do not need to pay immediately for additional equipment.

The best known manufacturers and models: characteristics and prices

Teplodar Kupper OK 15

The most famous domestic combined boiler, operating on coal, wood, pellets, natural gas (when installing a burner). Differs in time-tested reliability at low cost, good design of the furnace, ease of cleaning. Separately, it is worth noting the presence of 6 kW heating elements, with the help of which the coolant can be heated for a long time when solid fuel is completely burned out at night. Also, the owners note a rather pleasant stylish design and build quality.

However, there are also a sufficient number of disadvantages: a small loading opening and the firebox itself (firewood up to 35 cm), steel heat exchanger, relatively low efficiency, high soot formation.

Cost: 19,900-21,200 rubles.

Viadrus Hercules U22 D-4

One of the best combined gas-firewood boilers for heating a private house, and also one of the most purchased. The Czech model with a cast-iron heat exchanger is characterized by ease of use and a well-known durability, provided by good alloys and workmanship. The boiler has a fairly good efficiency of 80%, is absolutely omnivorous, has the optimal size of the firebox (firewood is 40-45 cm long), while it also has compact dimensions and a stylish appearance.

According to the reviews of the owners, with a strongly closed thrust valve, abundant soot formation is characteristic. The cast iron construction, depending on the power variation, weighs an average of 250 kg, therefore a reinforced floor is required for installation, and at least 3 people for transportation. Also a relative disadvantage is the price of the Czech model.

Cost: RUB 63,000-67,500

Roda Brenner Classic BCR-04

Another practically reference Czech combined boiler with a cast iron heat exchanger and a technologically advanced, efficient and practical design. The body is separated by a layer of thermal insulation, which reduces heat loss through the boiler modules, keeps the body relatively cold. Everything is also distinguished by Czech reliability, practicality during operation and cleaning, good efficiency.

According to the experience of installation and feedback from the owners, no shortcomings and malfunctions were found for more than 6 years of operation. It can only be noted that the price is still high for the average Russian buyer.

Cost: RUB 53,000-55,000

GEFEST VLOOKUP KSTGV-20

Inexpensive and compact double-circuit combined boiler of domestic production. Differs in good efficiency of 80%, achieved due to the excellent design of the heat exchanger. The primary heat exchanger is steel, but the secondary (for hot water supply) is made of copper. Almost always a BRAY-type gas burner with the well-known simple Italian SIT automatics is included in the factory configuration.

Please note that the maximum allowable working pressure is only 1 bar. It is also worth noting that the model is quite rare on the market.

Cost: RUB 23,500-26,400

Karakan 20 TEGV

Another domestic double-circuit model. It has the most simple design, is not picky about fuel, has a large loading opening and a firebox, as well as a heating element unit installed from the factory.

However, the heat exchanger is made of steel, the efficiency is only 75%, the weight is 101 kg, and the maximum allowable operating pressure is 1 bar. There were no service complaints for more than 5 years of operation.

Cost: RUB 22,500-25,000

Prices: summary table

| Manufacturer and model | Heat exchanger material | Number of contours | Efficiency,% | price, rub. |

| Teplodar Kupper OK 15 | steel | single-circuit | 78 | 19 900-21 200 |

| Viadrus Hercules U22 D-4 | cast iron | single-circuit | 80 | 63 000-67 500 |

| Roda Brenner Classic BCR-04 | cast iron | single-circuit | 80 | 53 000-55 000 |

| GEFEST VLOOKUP KSTGV-20 | steel | double-circuit | 80 | 23 500-26 400 |

| Karakan 20 TEGV | steel | double-circuit | 75 | 22 500-25 000 |

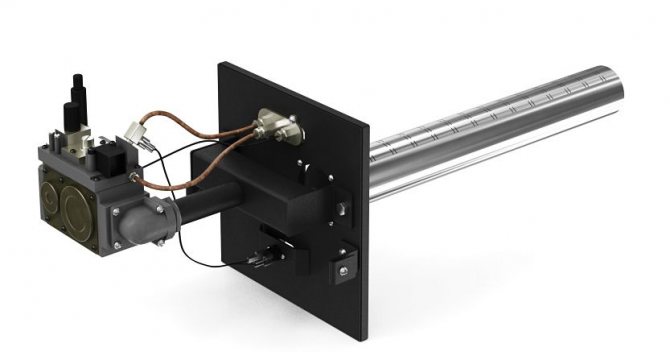

How to select a gas burner for a solid fuel boiler

Model AGG-13K

Universal gas burners for solid fuel boilers, not belonging to the factory accessories of specific models, are suitable for all boilers, since they have a fairly simple screw fastening. Exceptions are burners designed for a specific model range. Usually these are burners from the same manufacturer as the boiler. Their name or characteristics indicate, for example, "... for boilers Teplodar".