Roda Brenner Classic BCR-04

- Power, kWt:

23.3 - Number of circuits:

1 - A type:

floor

Advantages:

- thermal insulation

- fuel versatility

- the presence of a thermometer and manometer

- high efficiency

- price

Disadvantages:

- no

Choosing a heating boiler, the first item that the buyer pays attention to is the type of fuel used in the work. The reason lies not only in the significant difference between the price tag, for example, for gas and electricity, but also in the availability of this or that energy carrier.

Both problems are sometimes completely, sometimes partially solved by a combined heating boiler designed to operate with several types of fuel.

Features of heating with combined boilers

The main advantage of the combi boiler lies in its name. This device can operate with several types of fuel, which allows you to adjust energy costs directly during the operation of this equipment.

As an example, we can cite a situation when at some period it is much more profitable to heat a house with wood than with a diesel engine. This can happen with electricity and with liquefied gas.

Important! Combined heating boilers are mostly non-volatile, that is, they are able to continue normal operation during a power outage. In their design, as a rule, two combustion chambers are provided, each of which is designed to burn its own type of fuel. Some of the models are additionally equipped with heating elements that insure the equipment performance.

The obvious advantages of multi-fuel boilers include the following points:

- Independence from the presence of one energy source.

- The ability to use exactly the currently available type of fuel.

- Possibility to equip several segments of the heating network, including underfloor heating, if the boiler is equipped with several heating circuits.

- Cost savings due to the use of the most profitable fuel at the moment.

- One combi boiler with several fireboxes takes up less space than several mono-fuel units.

Some combined boilers are equipped with automation capable of independently switching equipment between types of fuel, when the supply of one of them for any reason stops. For a private house, such a solution is extremely useful, since it removes the need for the owner to participate in the operation of the heating system.

Naturally, like any heating boiler, multi-fuel equipment has a number of disadvantages, which must be taken into account when deciding whether to install it:

- The cost... It is noticeably higher compared to mono-fuel boilers.

- Need organization of storage places of the solid or liquid fuel used.

- Need organization of a separate boiler room... Although it can be said about combined boilers that they are compact, they still surpass electric or gas units in size. In addition, work on the same coal or diesel fuel is too “dirty” to place the heat generator not in a separate boiler room.

- Overall design complexity, which, in fact, has a direct impact on the cost, and also complicates maintenance.

Important! Combined boilers also include models with only one combustion chamber. To convert them to alternative fuels, the burner needs to be replaced.Considering that such devices are often also equipped with heating elements, without replacing the burner, it is possible to work on electricity.

What are the advantages of electric wood boilers?

The main fundamental disadvantage of any solid fuel boiler is that the homeowner is more or less attached to it. After all, this device, unlike its gas counterpart, has to be “fed” only manually. This problem is partially solved in boilers with an automatic fuel supply system, but they can only work with fine coal (with the size of individual parts from 5 to 25 mm), pellets or bulk fuel - shavings, chips or hulls of sunflower seeds. If the owner of the house plans to use ordinary firewood as fuel, the automatic feed system will not help him in any way.

Boiler with automatic fuel supply system

On average, you have to put firewood in the boiler every three hours. What if you can't do it on time? Of course, the coolant in the heating system will cool down, and with it the air in the rooms. You will also have to forget about good rest: you will have to get up at least twice a night to renew the supply of firewood, otherwise you will wake up in the refrigerator in the morning.

The owner of a combined boiler operating on wood and electricity can only dream of such problems in a nightmare. If the stock of firewood in the firebox is not updated in a timely manner and the temperature of the coolant begins to fall, smart automation will automatically turn on the electric heating elements and the heating system will thus be resumed.

Another advantage of boilers of this type is that they are quite simple to manufacture, and therefore relatively cheap. For those on a budget, such equipment is most suitable.

Separate boiler room

Varieties of combined boilers for heating a private house

Among the combined boilers for heating a private house, you can choose models that meet the needs of even demanding buyers, of course, within reason.

Depending on the design features, multi-fuel heat generators are divided into several types, which allows you to choose an option without overpayment for specific operating conditions.

Single and double-circuit boilers

Heating of the house can be organized by combined boilers with a different number of circuits:

- Single-circuit boilers - designed for heating only.

- Double-circuit models - with an additional circuit providing hot water supply.

Models that operate only on a heating circuit are usually more reliable due to a simplified design. Because of this, they are also cheaper. On the other hand, when an indirect heating boiler is connected, heating is combined with DHW. True, such a bundle is more expensive than the cost of two-circuit models.

Combined boilers with two heating circuits are equipped with either a coil or a storage tank. In the first case, hot water taps receive rapid heating of water for domestic needs, but with limited capacity, depending on power.

In the case of a storage tank, it provides household supply without temperature fluctuations in the case when hot water is used by more than 2 - 3 consumers.

Some models, regardless of the number of circuits, are equipped with a cooking hob. Additional fuel is not consumed to warm it up, and therefore, you can warm up breakfast, roughly speaking, for free.

Fuel types

The combined boiler for the home can be dual-fuel and triple-fuel. The first group includes models with the following main fuel bundles:

- Gas-solid fuel... An electric wood-burning boiler is a prime example here, since it is believed that firewood itself is a cheap source of energy.However, this is true if they are mined on their own. Coal and pellets can also be used as solid fuel. This design is usually poorly automated.

- Gas-electricity - relatively compact, the main fuel is cheap gas. The heating element is connected to work either for rapid heating of water, or when the main heat carrier is turned off. Among the advantages, variability should be noted. It is also necessary to pay attention to the fact that in most of such models, electricity is spent not on heating the coolant, but on maintaining its temperature.

- Solid fuel-electricity - is popular in non-gasified regions. By design, this is a classic solid fuel boiler, but equipped with a heating element, which is capable of operating simultaneously with the firebox, or even independently, maintaining the nominal operating mode of the heat generator. Heating a house with an electric wood boiler is especially beneficial in non-gasified regions with wooded areas.

Three-fuel combined units are less popular, but among all the options, you can pick up quite interesting models that are easy to use:

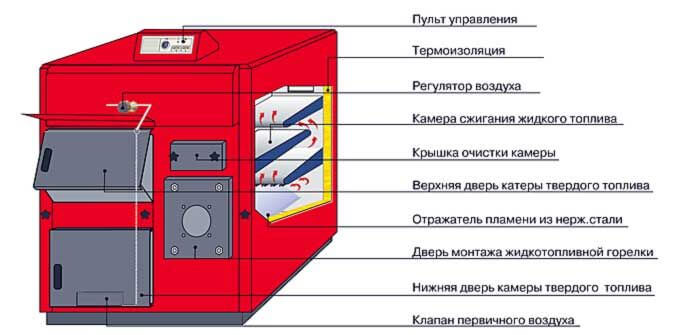

- Gas-liquid fuel-solid fuel... The best models are structurally uncomplicated and have two fireboxes. In the first, either gas or liquid fuel is burned, which depends on the installed burner (it can be changed), and in the second, only solid fuel.

- Gas-solid fuel-electricity - are considered the most versatile, since they use three completely different energy carriers in terms of availability, reliability, and cost.

It should also be noted that combined boilers can have both separate furnaces, each of which operates on its own heating circuit, and one common combustion chamber. True, the latter option is typical mainly for home-made heat generators and constantly receives rather conflicting reviews.

Boilers with open or closed combustion chamber

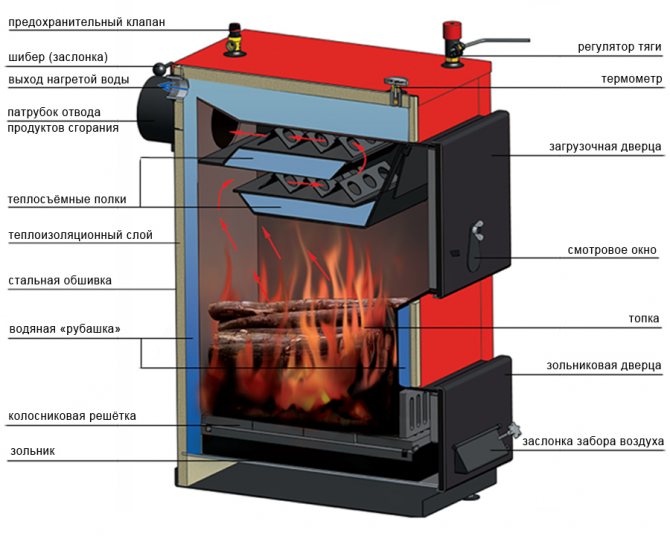

The type of combustion chamber is another criterion by which the combined boilers are divided into subspecies:

- Open chamber models... Here, combustion products are removed by natural draft in the chimney. The air for fuel combustion is also sucked in without auxiliary devices directly from the boiler room.

- Equipment with a closed combustion chamber - works exactly the opposite. Combustion products are forcibly removed, as well as air is taken in to support the combustion process. It should be noted here that the air mass is supplied from the street, that is, oxygen is not burned in the room.

The operation of a closed chamber in any case depends on the electricity that powers the fan, so in terms of autonomy, it may not be the best choice.

How to choose an electric wood boiler?

Before buying a boiler of this type, you should decide on some of its parameters:

1. Boiler power

The selection of power is carried out in the same way as for any other boiler. It is best to order a heat calculation and a heating system design from a specialized company. If this is not possible, you can use the average value of the specific power of heating systems, which is 130 W / per sq. m for houses with an area of 100 - 150 sq. m and 85 W / sq. m for houses with an area of 400 - 500 sq. m. Multiplying the specific power by the heated area, it is possible to determine the required power of the boiler. For example, for heating a house with an area of 125 sq. m you will need a unit with a capacity of 125x130 = 16 250 W or 16.25 kW.

Do not forget that an electric wood boiler has special requirements for home wiring. Make sure that she will be able to "pull" the unit you like.

2. Weight

Devices of this type, especially powerful ones, are quite massive.Before purchasing a boiler, evaluate the load-bearing capacity of the floor and the possibility of strengthening its structure in the room where the boiler room will be built.

3. Material and construction of the grate

In the case of a predominance of wood fuel, you should choose a boiler with a cast iron grate. If you plan on using bulk fuel frequently, choose a model with a honeycomb-type grate, which is made of ceramic and steel.

4. The presence of a second heat exchanger

Today, a combined firewood-electricity boiler with the ability to connect to a DHW circuit is a fairly popular product, but it is not suitable for everyone. The fact is that at the moment of using hot water, all the attention of the boiler switches to it. In this case, the heated coolant ceases to flow into the heating system, since it is it that is used to heat water in the second heat exchanger. If for some needs you have to open the hot water tap for a long time, the installation of a double-circuit boiler does not make sense. In this case, you will simply be left without heating.

5. Heat exchanger material

Cast iron heat exchangers are considered the most preferred. They are not susceptible to corrosion, due to their high heat capacity, they can smooth out short-term drops in boiler power and do not have weak points in the form of welding seams, since they are prefabricated. The steel heat exchanger is a welded structure, it is less durable and is afraid of rust, but, unlike cast iron, it does not collapse during sudden temperature changes.

Recommendations when choosing a boiler

Studying any rating of combined boilers for a private house, you will notice that each model has its own characteristics, both in terms of operation and in physical dimensions and design. In fact, on sale you can find units operating with four, and even with five types of fuel. It is from the availability and cost of the energy carrier that one should build on when buying.

Important! Combined boilers, designed for unequal use of energy resources, when switching from the main type of fuel to the reserve one, can therefore have a serious spread in efficiency. Also, when choosing, the planned costs for the season are taken into account. When gas is available, questions usually do not arise, since it remains the cheapest. It is enough to purchase a model of the gas-electricity type, thereby ensuring uninterrupted and efficient heating.

Based on the costs of the heating season, the list from the cheapest energy source to the most expensive is as follows:

- Natural gas.

- Pellets.

- Firewood.

- Coal.

- Liquefied gas.

- Diesel.

- Electricity.

The location of the items in the list may vary depending on the actual cost of the energy carrier in a particular region.

Reviews of universal solid fuel boilers with built-in heating elements: advantages and disadvantages

| Benefits | disadvantages |

| Only 10-15% higher cost, which makes the purchase of the combined model more profitable from a financial point of view | Quite simple functionality, lack of advanced automation |

| Partial elimination of the main drawback of TT boilers - the need for constant additional loading. According to the owners of even rather large houses with an area of 150-200 m 2, the power of heating elements is sufficient to keep the temperature of 17-19 ° C until the morning. | In universal boilers for wood and electricity, only steel, corrosion-prone heat exchangers are used. There are no cast iron models today. |

| Saving space in the boiler room | Lower efficiency of heating elements |

| The ability to use two sources of thermal energy at any time | Usually smaller firebox volume |

| Availability of double-circuit models | Limited choice of models, there are almost no foreign manufacturers on the market |

| The ability to use electricity for heating only at night at reduced rates (you need an electric meter that differentiates consumption by time zones) | The heating element unit has a low power and, despite the fact that it can work autonomously, it is intended only for maintaining the temperature, and not for full heating. |

Combined boiler capacity calculation

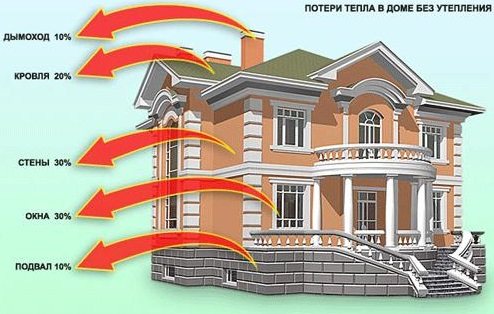

In theory for heating 10 sq.m. area, you need to spend 1 kW of thermal energy. However, such a calculation is highly simplified and conditional, it is adjusted based on the following factors:

- The degree of insulation of the building as a whole... Here, not only the material of the walls is taken into account, but the number of openings, which doors and windows are installed.

- Climatic features of the region... If winter is characterized by severe frosts, the difference between the ambient temperature and the mark to be achieved increases. This means that the equipment should be more powerful.

- Number of floors and ceiling heights... In fact, it will not be necessary to heat the area of the house, but the volume of the contained air.

Thus, the power surcharge for a multi-circuit combi boiler can be 25 - 30%. Detailed calculations are carried out by specialists.

disadvantages

The main disadvantage of this type of equipment continues to be its high cost. This model will have to spend approximately 1.5-2 times more funds than boilers operating exclusively on one type of raw material.

Among the minuses, one can also note the limited power of the electric heating element, the maximum performance is no more than 25 kW.

This power is quite enough for heating a residential building and small industrial buildings, but the difficulty lies in the fact that during the operation of heating wood boilers, electricity in the water heating mode, the performance may not be enough to heat the room to the required temperature.

Is it profitable to heat the house with a combined boiler

Variability is the main trump card of the combined boiler. With the correct selection of a heat generator for specific operating conditions, heating costs are reduced. In addition, if there is a shortage of one of the types of fuel, you can always switch to another. It all depends on the price tag for the energy carrier and its availability.

In non-gasified coal-mining regions, it makes sense to install combined boilers, in which coal is the main fuel. Usually the price tag for this energy carrier in such an area is below average. If there is access to gas, the situation becomes even more simplified, and solid fuel goes into the reserve category.

In the case of installing a multi-tariff meter, at night, when the cost of electricity is noticeably lower, it makes sense to use electricity to maintain the temperature in the rooms. The above options for operating a multi-fuel boiler are nothing more than examples of situational savings.

Combined boiler TT-electricity

A combined firewood-electricity boiler will be more expensive than a conventional TT heater, but not by much. For example, a domestic 14 kW Topol-M unit will cost 30 thousand rubles. The design of such models is standard:

TT boiler with pellet hopper.

- firebox;

- heat exchanger;

- heat exchanger tank;

- insulated body;

- automation system.

The electric heating element is built into the storage tank of the boiler. The heating element is easy to change if it burns out. To do this, it is enough to unscrew the faulty heating element and screw in a new one. The heating element can work independently, or it can simultaneously burn solid fuel. This approach is useful when you need to quickly warm up the system or to extend the periods between bootups.

As you know, in conventional TT boilers, firewood must be thrown every 4 hours, in pyrolysis heaters this time is increased from 6 to 8 hours, but no more. If there is no storage tank in the circuit, but temperature drops are inevitable. The heating element helps to smooth out the drops. You can install a thermostat and connect it to the heating element. This will keep the temperature at the same level.

Before making a warm floor in a bath, you need to calculate the optimal pipe pitch.

At a minimum, the height of the underfloor heating screed should be 7 cm.

In addition, the electric heating element can keep the water temperature in the system at the minimum acceptable level when you are away. Naturally, it is simply pointless to fully heat the house when you are not at home for several days.

Installation Requirements

Almost all combi boilers are floor standing and require a separately equipped boiler room. In addition, when installing them, it is imperative to comply with a number of fire and electrical safety requirements, as well as compliance with SNiPs. Below are the main features of the installation.

Premises

- The presence of a reinforced individual foundation for the installation of boiler equipment.

- Compliance with fire safety standards.

- Dryness in the boiler room, protection against moisture penetration.

- Non-combustible wall material.

- The minimum distance between the boiler and any wall is 300 mm.

Chimney

- Tightness of joints.

- No cracks or other mechanical damage.

- Thermal insulation that prevents the formation of condensation and ice, which can lead to blockage of the chimney duct.

- The head is at least 500 mm high.

Electricity grid

Here it is important to eliminate the likelihood of contact with water of any current-carrying elements, if any. Also a mandatory requirement is the correct selection of the cross-section of the supply wiring, which is calculated on the basis of the total power of the supplied equipment, the strength of the current consumed.

Top manufacturers

Combined heating boiler ratings can include dozens of models from a wide variety of manufacturers. Among them there are those that are especially popular with buyers and are rightfully considered one of the best.

Protherm

This European manufacturer of heating boilers is distinguished by a wide range of products with more than 90 products, including heat generators of almost any kind, including innovative condensing models. Products are delivered to more than 25 countries from Europe, Asia and Africa, where they have earned the trust of consumers.

Protherm boilers are certified according to ISO 9001, have an affordable price for a wide range of buyers and a rich model range. In addition, the manufacturer provides professional service both through its own services and through partner companies, whose employees must undergo special training.

Roda

The products of the German manufacturer Røda are represented on the domestic market by electric, gas, solid fuel and, of course, combined boilers. Roda is a climatic equipment of European quality with service throughout the Russian Federation and a wide network of dealers.

Roda solid fuel boilers all have natural draft, and the combustion intensity is regulated by means of a thermomechanical regulator. On the other hand, the heat generator can be retrofitted with automation. It is also possible to install a control unit and a forced air intake fan.

ZOTA

The domestic manufacturer ZOTA offers customers, among other things, combined heating boilers for wood and coal with the ability to connect heating elements as an option.

They differ in an affordable price tag, there are models with a burner.Some solid fuel heat generators fully provide long-term combustion, which, depending on the type of energy carrier, is 8 - 12 hours.

Teplodar

Another domestic manufacturer that offers customers not only boilers, but also stoves, and even fireplaces. Teplodar has been working in the field of heating for 20 years and has more than 50 patents for unique developments.

High-quality materials are used in the production, and the reliability of the products is confirmed by various certificates. The model range includes horizontal heat generators of the Uyut series with a spacious firebox designed for firewood up to 50 cm long.

© 2020 All rights reserved

What are the combined boilers "wood-electricity"

Mixed-type boilers operating on solid fuel and electricity are always a floor-standing design, corresponding in size to conventional solid fuel models. Without the use of heating elements (tubular electric heaters), these are ordinary solid fuel boilers that burn not only firewood, but also coal, pellets, peat, coke, anthracite. The piping, installation and connection of universal boilers is carried out in the same way as for single-fuel boilers.

Model Kupper Practitioner.

What are they for and how they are used

Heating with electricity is the most expensive. However, if you use it as a backup heat source in a solid fuel boiler, you can get more benefits than it might seem at first glance:

- maintaining a comfortable temperature level after burning solid fuel for a longer period, for example, until the morning, if the load is burnt out at midnight;

- smoothing the cyclicity of solid fuel boilers, when excessive heating capacity is reached at the peak of combustion, and between charges it is greatly reduced. As a consequence, it is difficult to maintain a constant comfortable temperature level in the house;

- the possibility of faster heating of the coolant while using firewood and electricity at the same time;

- serious savings in boiler room space, since the installation of two separate single-fuel boilers requires at least 6 m 2 of free space.

Unlike gas-wood models, boilers for solid fuel and electricity are more justified, practically do not differ in cost from conventional solid fuel counterparts.

However, if there are financial possibilities, and space in the boiler room is not limited, we recommend installing two separate boilers, which can be connected in parallel (if the system is with natural circulation) or in series (if a closed heating system with forced circulation of the coolant is planned). There are several reasons for this:

- the functionality of a separate electric boiler is much higher, especially when using a room thermostat;

- the heating element unit reduces the volume of the combustion chamber by an average of 5-15 liters, which affects the duration of combustion of one load;

- The efficiency of heating elements during operation after burning out the load is reduced by several percent (from the standard 99%) due to the presence of constant draft in the firebox. In addition, the water jacket in which the tubular electric heaters are placed is usually not separated by a layer of thermal insulation, which adds heat loss through the heat exchanger (when the heating unit of even budget electric boilers has a layer of thermal insulation).

Boilers with a burning time of one fuel tab up to 7 days

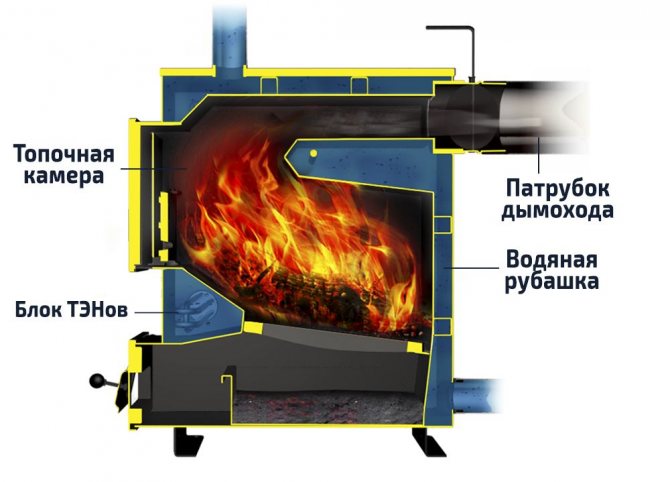

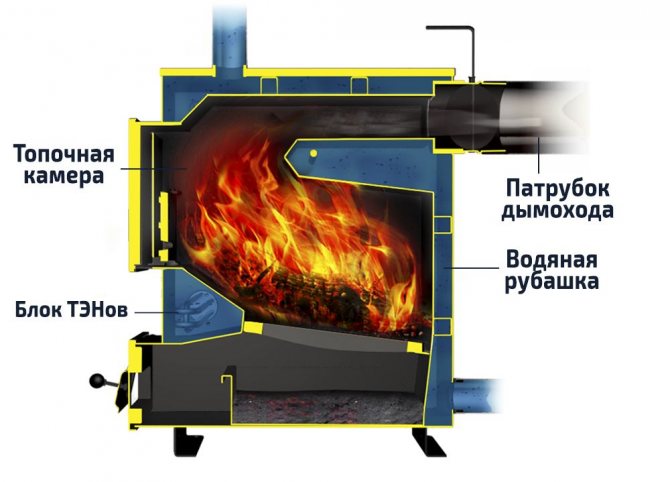

Device and principle of operation

Boilers with built-in heating elements have absolutely the same design as classic solid-fuel counterparts, with the exception of the space reserved for the heating element block in the water jacket, often this implies a decrease in the volume of the combustion chamber. The block of tubular electric heaters is removable, the heating part is placed directly into the heat exchanger, and the contacts are brought out through a hole in the wall of the boiler body.

Even 6 kW units work from a single-phase power network, they are controlled from the boiler, automatically or using a separate control panel, as in the Zota and Teplodar Kupper models.

The work algorithm is simple:

- When fired with wood or coal, the boiler works like any other solid fuel. The level of draft and temperature is maintained by a mechanical thermostat.

- After the combustion of the fuel load, the temperature of the coolant drops and, when the critical point is reached, the temperature sensor sends a signal to the heating element unit.

- If, during heating by heating elements, a new portion of solid fuel is loaded, the temperature of the coolant will rise and the heating elements will turn off.

This is how a ready-made replacement kit (PU, heating element and wiring) looks for Zota boilers.