The corrugation for the hood is in great demand. It has unique advantages in mounting and installation. In some cases, you can only install it, for example, in hard-to-reach places.

Corrugated pipe for exhaust

An air duct is required to connect the hood to the ventilation duct. There are different types of these structures, one of the most popular is corrugated. It is classified into the following types:

- Aluminum;

- Plastic.

The plastic air duct has smooth walls, and therefore, during operation, it does not create unnecessary noise. However, the aluminum construction is more popular. Its demand is due to the following advantages:

- Increased strength;

- Fire resistance, fire safety;

- Excellent aerodynamic properties;

- Large operating temperature range: from -30 to +250 degrees.

The aluminum pipe is suitable for use in both public buildings and apartments.

In order to choose the right corrugated duct, it is also important to correctly calculate the required diameter. In the instructions for the hood, you can find out what diameter will be optimal for the operation of the device. If you purchase an air duct with a diameter less than the minimum, the system will work in an enhanced mode, which can lead to breakdowns and a decrease in service life. The corrugated pipe has standard diameters: 10 cm, 12 cm, 12.5 cm, 15 cm.

Corrugation for hood

The corrugation for the hood can be of very different lengths. This parameter depends on the distance between the hood and the ventilation hole in a particular apartment. There are no length restrictions. However, it is worth remembering that the more bends at an angle of more than 90 degrees and the longer the length, the less performance the corrugated pipe will have. If the duct is very long, a higher capacity hood is required.

What is corrugation, and why is it needed for exhaust devices

In kitchen exhaust systems, corrugated pipes are used as air ducts through which the products of combustion and evaporation resulting from cooking are evacuated into the ventilation shaft. Devices differ in diameter, length and material from which they are made. Corrugation is made of galvanized and stainless steel, aluminum, as well as various polymers. Products for the removal of exhaust gases have a round or square cross section. It is selected taking into account the shape and size of the hood neck, as well as the ventilation duct itself. Corrugated pipes are also used to remove burnt gases in columns and hinged boilers.

Forced exhaust systems prevent the spread of unpleasant odors that are generated in the kitchen when organic compounds are burned. In addition, there is no need to open windows to check the kitchen, and fat evaporation does not settle on the cladding, furniture and ceiling, so the room is always neat and tidy.

Installation recommendations

You can easily run the corrugated air duct from the hood in the kitchen yourself. The corrugation is flexible and easily bypasses any corners.

Read the following guidelines before installing:

• Before installation, stretch the material as much as possible - this will reduce the noise level during the operation of the exhaust system;

• use special clamps as fasteners;

• put a grill with a non-return valve in the ventilation duct - this will ensure the supply of fresh air to the room;

• the device is not attached completely at first (it is finally fixed after the installation of the structure);

• if necessary, the shape and size of the corrugation are deformed to fit the hole;

• the transition sleeve is softened (heated with a construction hairdryer) and stretched over the junction;

• mounting tape is used for fastening the coupling;

• the corrugated pipe is fixed to the ventilation duct with a clamp, to the grille - with a flange.

The main rule when installing the air duct is to provide a minimum of turns for the efficient and quiet operation of the exhaust device. You can reduce the noise from vibration of the corrugation by gluing it with metal tape on three sides.

Corrugated pipe for exhaust: the advantages and disadvantages of the device

Consider the advantages and disadvantages of corrugated air ducts for hoods. First of all, it should be noted the ease of installation and the ability to bend the structure at a certain angle. In addition, several sections can be connected at the same time using clamps.

The air duct stretches freely and can return to its original state. The flexibility of the design provides some reduction in the noise level during operation of the hood. Due to these properties, corrugated channels are used in rooms with a non-standard layout and in conditions of limited space for arranging ventilation systems.

Please note that the aluminum corrugated duct can be easily divided into sections of the desired length using scissors. In comparison with plastic and metal counterparts, the price of the device is much lower. It should also be noted that the corrugation is resistant to high temperatures. The air duct made of aluminum can withstand up to + 300 ° С, so its ignition is completely excluded.

Table 1. Disadvantages of aluminum ducts

| Lack of device | Description |

| Complexity of cleaning | Since the corrugation has a relief surface, carbon deposits and fat deposits accumulate on it (in comparison with smooth types of air ducts) faster. This makes it difficult to clean the device. |

| High noise level | Compared to exhaust ducts (smooth-walled) made of plastic or steel, the noise level of the aluminum corrugation during operation is significantly higher. |

| Unattractive appearance | Corrugated air ducts, in comparison with plastic ducts, have a less attractive appearance. For this reason, some difficulties arise when decorating the kitchen interior (you need to figure out how to close the corrugation). |

Types of pipes for exhaust

For the installation of exhaust equipment, the following types of pipes are mainly used:

- smooth plastic (can have a round or rectangular cross-section);

- corrugated aluminum or plastic.

Properties of smooth plastic exhaust pipes

The plastic exhaust pipe is not corrosive. This is of great practical importance in conditions of constant formation of condensation in the ventilation system: no internal cleaning is required and the service life of the product is increased.

The smooth inner surface allows for maximum airflow with minimum noise.

Most often, PVC products are used for kitchen hoods. Their significant advantages are:

- tightness of the structure;

- light weight;

- ease of installation and transportation;

- high strength and durability;

- low cost.

The ventilation plastic pipe has insufficient fire safety. It is not recommended for use with air temperatures exceeding 50 ° C.

Round plastic pipes have less resistance than rectangular ones, so their efficiency is higher. However, the flat rectangular exhaust pipe fits better into the kitchen interior.It can be easily positioned along the wall above furniture cabinets and under the ceiling.

Description of corrugated ventilation pipes

The main advantage of using corrugated ventilation pipes is the ease of their installation, which does not require additional connecting elements.

If the stove is located at a considerable distance from the outlet of the ventilation shaft, the use of a flexible pipe for the hood is most preferable.

It should be remembered that the corrugation for the hood has a lower throughput and creates a higher noise level compared to a smooth pipe, since the unevenness of the inner surface contributes to the formation of vortex flows.

But there are also advantages of using corrugated pipes made of aluminum:

- flexibility, which allows them to be used in rooms of complex configuration;

- lightness and compactness - the three-meter section when folded is one meter;

- operation at temperatures from -30 to +120 ° C;

- lower price compared to plastic construction.

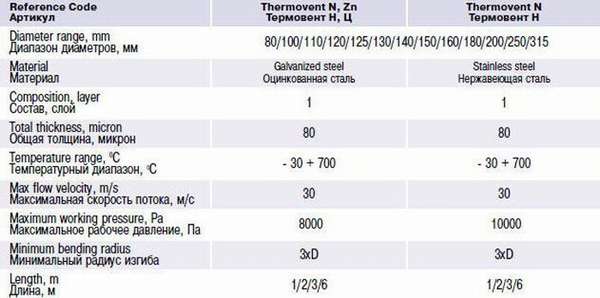

Technical characteristics of corrugated pipe for ventilation

Before purchasing a corrugated pipe for extraction, you should carefully study their technical characteristics and properties. Air ducts for domestic use are flexible and semi-rigid (semi-flexible). The first type of devices withstands bending and tensile deformations well with the possibility of restoring the original state. Using a flexible pipe, you can build an air duct of any configuration and a large number of corners.

The basis of flexible corrugation is a spiral-type wire frame, on which aluminum foil, polymers, or combinations of these materials are stretched.

The main characteristics include:

- device diameter - 100-500 mm,

- resistance to temperatures up to + 100 ° С,

- a bend amount equal to half the diameter.

Flexible air ducts are available with or without thermal insulation. The filler (glass wool, mineral fibers) is used to suppress the noise level in the house during the operation of the hood.

Table 2. Technical characteristics of semi-rigid corrugated pipes

| Device parameter | Picture | Description |

| Material |

| For the manufacture of semi-rigid air ducts, galvanized or stainless steel, as well as aluminum, are used. |

| Permissible bending value of the product |

| This indicator directly depends on the diameter of the duct. It indicates the degree of bending of the product (for example, the bending radius must be at least 0.6 of the corrugation diameter). |

| Internal dimensions of the corrugation (diameter) |

| Air ducts for domestic and industrial use with a diameter of 50-400 mm are widely available on sale. |

| Temperature indicators |

| When choosing corrugated pipes, the temperature indicators of the products should be taken into account. So, stainless steel devices can withstand thermal stress up to + 800 ° C, with a galvanized surface up to 700 mm, aluminum - 250-300 mm. |

How to connect the hood

There are two operating modes of the hoods: recirculation mode and air extraction mode. In the first mode kitchen hood connection no need for an exhaust duct. Here the air passes through special filters, is cleaned and goes back into the room. This mode has to be used when the hood cannot be connected to the air duct of the ventilation shaft. If it is possible to connect the hood in the kitchen to the ventilation duct, then it is better, of course, to use the air extraction mode.

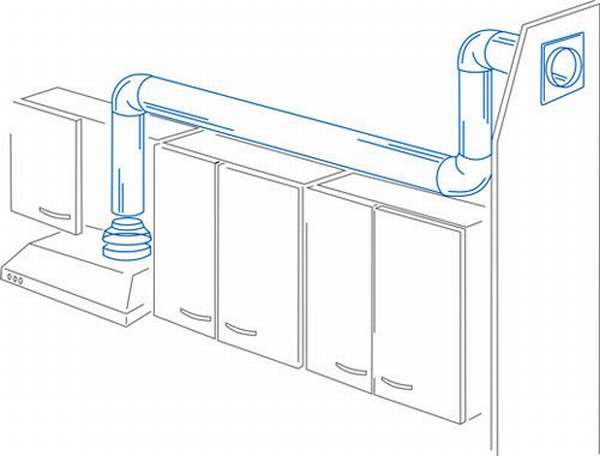

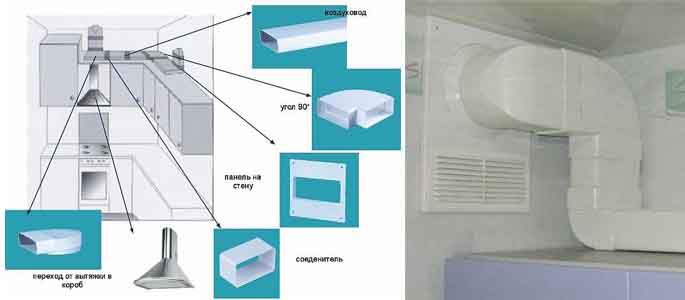

Connect the cooker hood ventilation can be done using a corrugated pipe made of aluminum or plastic, or using a structure made of special plastic ducts.

To the disadvantages kitchen hood connections corrugation can be attributed to noise during the operation of the hood. Due to the corrugated folds, such an air duct is difficult to clean.Also, the corrugation creates a not very attractive overall appearance of the kitchen, unless you are going to hide the corrugation behind a decorative element or behind a drywall box. Plus hood connections in the kitchen, using an aluminum corrugation can be considered a quick and easy installation. And also due to the high elasticity of the corrugated pipe, no adapters and connecting elements are needed, it can be easily bent at the desired angle.

hood connection in the kitchen

Advice: Do not bend the duct more than 90 degrees. This configuration can overload the cooker hood due to improper air outflow. In general, the fewer bends, the better the traction. Each turn reduces the extraction power by up to 10%.

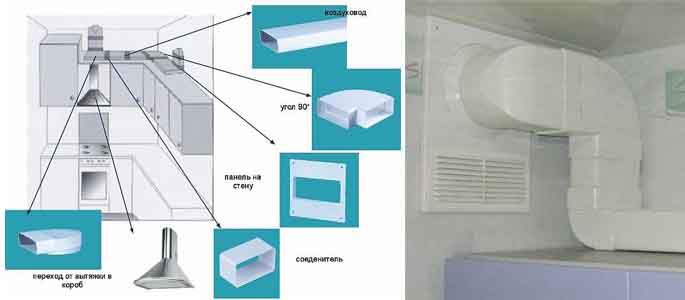

In turn, air ducts made of plastic structures are light, durable and practically silent, since the smooth surface creates almost no resistance to air. PVC air ducts can be in the form of rigid rigid ducts or elastic pipes. Such boxes lie on top of wall cabinets or pass under the ceiling and do not attract much attention.

A small adapter can be used to connect the cooker hood to the ventilation hole, if this hole is located directly above the stove.

kitchen hood connection

How to connect a hood using a corrugation

It is necessary to determine the diameter of the corrugated pipe based on the size of the exhaust outlet. Before installing the corrugation directly, stretch it as much as possible, this will reduce the noise during operation of the hood. The corrugation is fixed on the adapter flange of the kitchen hood with a clamp, it is not included in the kit, so you need to purchase it in advance. The corrugation is connected to the ventilation hole using a special grid. It is advisable to grease the joints of the corrugation with the exhaust pipe and the grill well with silicone sealant so that the performance and power of the air cleaner are not lost.

corrugated hood connection

How to connect a hood in the kitchen with a PVC air duct

Hood connection on the kitchen to a ventilation shaft using a plastic duct is similar to connecting a kitchen hood with an aluminum corrugation. In order not to be mistaken, draw in advance on paper the path of the duct from the hood to the ventilation hole and calculate how many corners and connectors are needed. An adapter from the kitchen hood to the box and panel to the wall is also required. All connections need to be coated with sealant, but in order not to be mistaken, first try to assemble the entire structure from the hood to the ventilation hole without sealant. If the plastic duct is sized and assembled correctly, disassemble and reassemble with sealant.

hood connection plastic duct

The hood is installed and connected to the ventilation duct, only connect the hood in the kitchen to the power supply through a separate socket or it will be a permanent connection through a safety circuit breaker. To prevent electric shock during operation of the hood, it must be grounded.

Used types of corrugation for household hoods

Aluminum corrugated pipe

Kitchen air ducts made of aluminum are the most widespread, since their price is low, and they are universal in use. Most often, users purchase a corrugation for a hood of 120 mm and 100 mm (less often - 150 mm). It is quite simple to choose such products, for which it is necessary to take into account the diameter of the inlet channel of the ventilation shaft and the exhaust gas outlet at the hood.

Advice! Corrugated pipe stretches well. So, 0.5 m of the duct can be stretched up to 3 meters in length without losing the properties of rigidity and resistance to high temperatures.This should be taken into account before buying an air duct for the kitchen.

Aluminum products have a long service life and excellent anti-corrosion properties. These devices are fire resistant, so they can be safely used as air ducts passing in furniture sections, decorative boxes, without fear of fire.

Plastic corrugation for ventilation

The purpose of the plastic corrugation for ventilation is the same as that of an aluminum installation - the removal of waste products of combustion and various vapors generated during cooking. Products have a round or square section, and due to their attractive appearance, the air ducts fit perfectly into almost any kitchen interior.

Plastic ducts have excellent throughput, besides, gases are discharged through them into the ventilation shaft almost silently. The smooth surface of the air ducts is effortlessly cleaned, maintaining a beautiful appearance for a long time. The products have one significant drawback - in comparison with their metal counterparts, they cannot withstand high thermal loads. For this reason, before buying a plastic duct, you should ask what the maximum temperature the product can withstand.

Other types of air ducts

There are a large number of types of air ducts that are used as outlet ducts for various communication systems. PVC corrugated pipes are most often used for ventilation in homes and industrial facilities. Most often, products with mineral fillers are used, which provide excellent sound insulation.

Galvanized boxes are also used for the installation of ventilation and exhaust systems of complex design. Such material is resistant to chemical reagents, does not corrode and has a long service life. The same applies to analogs made of stainless steel and copper, however, due to the high price for air ducts, it is impractical to manufacture large structures. At home, such products are ideal for arranging hoods, heating systems using solid fuel and gas boilers, requiring the installation of channels that are resistant to high temperatures.

Ceramic air ducts for kitchen hoods are available in round and square sections. These products have the highest thermal stability, since they can freely withstand loads over + 1000 ° C. Ceramic duct manufacturers give their products a 30-year warranty.

Installation rules and nuances

The corrugated exhaust pipe is ideal when the product is hidden in a closet. No adapters are required during installation, which saves money. The corrugated structure is flexible, it perfectly bends around corners, which allows you not to use additional fittings.

Before installing such an air duct, it is required to stretch the corrugation. Otherwise, creases will increase the noise level. The air duct is attached to the exhaust pipe. In this case, a clamp is used. It is also required to fix the corrugation on the ventilation hole. For proper installation, you should heed the following recommendations:

- In the event that the ventilation outlet is located in the opposite corner from the hood, the corrugated pipe can be run under the ceiling. This option is suitable if you have false ceilings. In this case, the bend will not be sharp, which means that the performance of the system will not decrease;

- It is also important to pay attention to the diameter. The narrower the duct, the more resistance will be provided to the air flow. A narrow stroke will negatively affect system performance. For this reason, it is not recommended to use a rectangular type air duct for a round type hood.The adapters that have to be used in this installation will significantly reduce performance. Therefore, the best choice is an aluminum corrugated structure;

Installing the corrugation for the hood

- It is imperative to purchase a grill with a non-return valve for the ventilation hole. It is needed so that the duct does not completely close the passage, and the flow of fresh air into the house is preserved. In such a grill there are holes for natural ventilation of the kitchen and for the outlet of the hood. A corrugated pipe is mounted in the second hole;

- The system performance should be equal to 3 kitchen volumes. However, this parameter is rather difficult to determine. For this, an anemometer is used. It is installed in the duct and then dismantled;

- You can understand if there is a reverse thrust by leaning a sheet of paper against the ventilation grill. The sheet should hang and float without the aid of a hand. If there is a reverse draft, it is almost pointless to install an air duct, because it will have a low performance. This simple experiment will help you determine the effectiveness of the system even before it is installed;

- One of the basic rules is that a corrugated pipe should have a minimum of turns exceeding an angle of 90 degrees. Otherwise, with each turn, the power of the system will drop by 10%.

The air duct is usually selected after the hood has been selected. The reason for this is that the aluminum pipe must have a certain diameter, which is determined depending on the hole in the hood.

Kits are on sale in which the duct and corrugation have matching parameters and a harmonious design.

However, it is not necessary to purchase a kit. If you make all the calculations in a timely manner, look at the instructions for the device, you will be able to choose the right corrugation that will ensure efficient operation of the equipment.

How to choose the right corrugation for the hood - our editorial team's recommendations

When choosing air ducts, first of all, you should take into account the dimensions of the corrugation for the hood. The diameter of the product should be 1–2 cm larger than the dimensions of the outlet socket (hole) of the unit. This is necessary in order to reduce the load on the electric motor and the noise level.

For AOGV, it is recommended to develop the design of the exhaust ducts in such a way as to minimize the number of bends. If it is necessary to connect the air duct hoses or turn the duct in a certain direction, use the appropriate fittings. To prevent air from entering the channels, valves of the membrane type or axial analogs with a polymer disc are installed. As for the cross-section of products, it is better to install round pipes, since they provide the most efficient gas outlet.

As for the structures for the kitchen hood, it is worth considering the properties of the materials from which they are made. Flexible metal air ducts are compressed or stretched during installation and can be easily mounted at any angle. They are safe for humans, unlike plastic counterparts, which release toxic substances over time when heated.

Advantages and disadvantages of corrugated pipes for ventilation

The technology of installing ventilation ducts from the hood to a stationary duct in the wall of a building until recently was reduced to the installation of rigid structures made of metal or plastic.

Sheet metal was cut according to part templates and assembled into a general structure after processing each segment. This technology had many drawbacks - only an experienced tinsmith could assemble the box.

And the assembly of standard metal elements did not allow making the duct an attractive shape.

Plastic boxes also did not solve the problem - the design was far from perfect, with the same angular bends and profiles that could not be bent.

Corrugation for ventilation solved several problems at once:

- the need to involve a tinsmith to work has disappeared, today you can do the installation yourself;

- unlike sheet metal pipes, metal corrugation turned out to be much more durable;

- a corrugated hood is more efficient and reliable compared to composite structures - there are not a lot of joints, which means that the air exhaust hose is more sealed;

- today such pipes are presented in a large assortment in any hardware store, while the price is quite democratic and affordable;

- the convenience of installing such air ducts is obvious - the segment can be given almost any shape and direction of bending;

- simplifies the installation of the corrugation and the fact that reliable tension clamps are used for fastening, standard adapters are used to connect several segments, which are very accurately sized to the sleeves;

- the sleeve has a low weight, which allows it to be used when laying in a plasterboard structure and above a stretch ceiling made of PVC film;

- metal sleeves can withstand temperatures up to 600 degrees;

- aluminum, stainless steel and plastic allow you to use household chemicals for cleaning to remove grease and soot from the surface of the air duct.

But as for the negative aspects, it is worth mentioning here that ventilation from the corrugation must be laid carefully. Shocks, unnecessary forces and pipe fall should not be allowed.

The second disadvantage is the need to use a whole arsenal of materials and devices during cleaning, from a spray gun to a medium-bristled brush, to effectively remove fat deposits.

True, it is worth noting that it is quite rare to remove this plaque with an efficiently working hood.

Features of the installation of a corrugated air duct for the hood

Materials and tools used during installation

We will analyze what tools and materials are required to install ventilation corrugated pipes. The first step is to choose the correct air duct itself to connect to the hood. To connect the corrugation to the ventilation duct, you need to purchase a casing with a flange. To fasten it, you will need self-tapping screws and a set of screwdrivers.

To connect the hose sleeve to the grill, you need to purchase metal clamps of the appropriate diameter. In some cases, an external ventilation grill equipped with a non-return valve may be required. To exclude the penetration of air into the channels from the outside, use a silicone sealant. For metal corrugation, aluminum tape may be required.

Advice! Quite often it happens that the air duct openings in different parts of the system can have different sections or diameters. This issue is quite simple to solve, for which you need to buy the appropriate adapters.

Scissors are used to cut the aluminum corrugation for ventilation. Plastic counterparts can be shortened with a hacksaw, choosing the right blade.

Installing the corrugation on the hood: step by step instructions

In this section, we will consider how to install a corrugation on the hood in the kitchen with a detailed description of all stages of installation work. Below is a table with step-by-step instructions and illustrations.

Table 3. Step-by-step installation instructions for corrugated duct

| Stage of work | Picture | Description |

| Development of an exhaust system installation scheme |

| Taking into account the peculiarities of the kitchen, furniture sections and the location of the ventilation shaft, design a plan for the installation of the air duct. This will allow you to calculate the exact number of pipes, fittings, grids, clamps, fasteners. |

| Checking the length of the duct components |

| According to the scheme, prepare the sleeves of the required length for installation. If necessary, shorten the corrugation with scissors, a hacksaw. |

| Installation of a universal reducer on the exhaust outlet |

| Install a universal reducer on the exhaust outlet of the hood. This device will help you to mount corrugated air ducts of various diameters. |

| Corrugation connection with hood |

| Seal the edges of the gearbox with sealant. Install the sleeve, fix the clamp with the screw and screwdriver. |

| Fixing the channel to the wall |

| Fix the plastic (metal) duct to the wall using brackets with clamps. Mount the fasteners at a distance of 1 m from each other along the entire length of the structure. |

| Ventilation grill installation |

| Place the grating on the opening of the ventilation duct. Fix with self-tapping screws. |

| Duct to grille connection |

| Apply sealant to the flare of the grille and put on the neck of the air duct. Secure with a hose clamp. |

| Connecting the hood to the mains |

| Connect the hood to the mains. Check the operation of the exhaust system. |

Video "Features of connecting the hood and air duct":

Types of air ducts

The connection between the fume cupboard and the ventilation duct is an air duct. This flexible lightweight hose is available in the following materials:

- aluminum strip twisted into a round movable frame, corrugation;

- plastic thin-walled pipe;

- pipe made of other metals - galvanized, copper.

Corrugation is the most common duct. There are several reasons for this. Easy installation a relatively cheap product and its ability to withstand large temperature differences make the material suitable. In addition, the aluminum duct is durable and does not react with aggressive vapors.

The pipe is wound from a solid strip of aluminum, has no joints and is very flexible. In its original form, a half-meter pipe stretches up to three meters, which makes it easy to fit it to any distance. The requirement for creating thrust will be the compliance of the pipe conditional passage with the declared hole in the hood's passport. The longer the suction pipe, the more powerful the exhaust system must be.

The corrugation is available in various diameters from 10 to 15 centimeters. When buying it, you should immediately stock up on clamps for fastening and a suitable ventilation grill.

The existing plastic and metal air ducts have smooth inner surfaces and, in comparison with the corrugation for the hood, are less noisy, since they have less resistance.

How to connect the corrugation to each other

The simplest and at the same time reliable way to connect several corrugated sleeves to each other is to use aluminum tape. To obtain a one-piece channel, it is necessary to join the edges of the air ducts, and then fix them with tape.

This material will reliably hold the constituent parts of the duct and prevent depressurization. Also, for connection, adapters are used, on which the sleeves are fixed with clamps (with preliminary application of sealant).

How to connect the corrugation?

Hello dear visitors of the site elektrik-l.ru. Today I would like to talk about how to connect corrugation?

A corrugated pipe (or as they usually say - corrugation) is very widely used when installing electrical wiring in an apartment or a private house. Corrugation is intended for:

· Protection of electrical wires and cables from mechanical stress;

· Prevents moisture ingress;

· Gives additional strength to the cables when the building shrinks.

When installing electrical wiring indoors, PVC corrugation is used, since it is non-combustible. Before laying electrical wiring, you must first pull the cable inside the corrugation. For this, it is supplied with a special thin wire (broach). Sometimes the length of the lines can be very long, and reach several tens (and hundreds) of meters. Then stretching a long cable in a corrugation is a very serious problem. In such cases, you have to use several pieces of corrugation. And then the question arises: "How to connect the corrugation to each other?"

Usually, all installers and electricians proceed as follows: they join the pieces of corrugation to each other and wrap the joint with electrical tape. I myself sometimes do this)). I believe that this method can be used as a temporary connection of the corrugation.

Corrugation connection with electrical tape

Recently, I have been trying to use a different method of connecting the corrugations (albeit if the client is willing to pay for it).

In fact, there is a more reliable and aesthetic way to connect corrugated pipes - the use of special couplings. The sleeve is a small plastic tube into which the ends of the corrugated pipes to be connected are inserted. These couplings can be of various types - straight, angled (for making turns) and triple (tee for connecting three pipes).

The connection of the corrugation with the help of couplings is very simple, for this you do not need to perform any complex manipulations: just insert the ends of the corrugation into the tube and that's it.

Corrugation and coupling

We insert one end of the corrugation into the sleeve

Corrugation connection is ready

Angrily! But a little expensive ((. Compared to using electrical tape. True, electrical tape sometimes goes a lot for these corrugation joints.

Here are a few more photos of the corrugation connection, only this time on the cable.

We put a sleeve on the cable

We insert a tube into the corrugation

We drag the cable into the second corrugation

Corrugation connection is ready

That's all I wanted to tell you about the corrugation connection.

How to hide the corrugation from the hood in the kitchen

Consider how you can hide the chimney in the kitchen. The photo shows one of the options for masking the duct. For these purposes, drywall or plastic boxes are used. In the first case, you need to make a frame from profiles, and then sheathe it with GKL sheets. The plastic structure can be purchased at a hardware store.

Also, the duct can be hidden inside the hinged sections of kitchen cabinets, having previously made holes for the corrugation of the corresponding diameter. If there is sufficient space between the ceiling and the curtain wall to fit the pipe, it can be routed from above.

How to hide a pipe from a hood in the kitchen: masking options

A ventilation pipe for a kitchen hood is not able to organically fit into most interiors. For this reason, you will have to take care of her disguise. And there are several options here.

Option number 1 - installation of a decorative box in which you can hide not only the air duct, but also the hood itself. To begin with, make a frame from metal profiles. It is securely fixed on the wall, and, if necessary, fixed on the ceiling. Angles and self-tapping screws are used as fasteners.

The finished frame is sheathed with sheets of moisture-resistant drywall. The advantage of this solution is that you have the opportunity to design this box so that it becomes an aesthetic and appropriate item in the interior of the kitchen. Painting or plastering to match the walls, wallpapering, decorative overhead elements - there are a lot of options.

Decorative box for hood and air duct

Option number 2 - masking the duct behind plastic panels. All work is carried out according to the scheme discussed above, but plastic panels are used instead of drywall sheets. This solution is relevant in cases where the ceiling is sheathed with them.

Note! On sale you can find ready-made boxes for that part of the pipe that goes directly from the exhaust pipe. They are distinguished by their lightness, variety of solutions and aesthetics.

Hood with a decorative box (casing) in the same style

Option number 3 - painting the ventilation pipe. This option is only appropriate when installing a plastic structure.

Option number 4 - installation of a furniture visor. If you have not yet purchased kitchen furniture, then think about having a so-called visor in the upper part. The pipe laid between it and the ceilings will be almost invisible.

However, if desired, a similar visor can be ordered for a ready-made furniture set.

The plastic pipe is practically hidden by the backlit furniture visor

Option number 5 - masking the air duct in the protruding part of the false ceiling. Effective, but if you need to get to the pipe, you will have to disassemble and reinstall the ceiling. Not without the help of specialists who will need to pay.

Masking a ventilation pipe in a suspended structure

Option number 6 - laying a pipe from the hood inside a wall cabinet. In this case, it must have a great height.

Plastic duct in a kitchen cabinet

Option number 7 - non-standard solution:

As you can see, the selection and installation of the ventilation pipe for the hood can be done independently. The main thing is an attentive and responsible approach. But if you are not confident in your abilities, invite masters with experience in the relevant work. Indeed, what you breathe in the kitchen depends on the quality of the installation of the air duct.

Air duct maintenance rules. The need to replace the corrugated pipe for the hood

Smooth-walled plastic pipes are easy to clean, especially if the duct structure consists of several sections of small length and a corrugation diameter of 100 mm (so that a hand can freely pass inside). The sections are disassembled, cleaned of dirt, and then installed in their original place. The situation is more complicated with an aluminum corrugation with a relief surface. Grease, soot, carbon deposits and dirt accumulate in the folds of the structure for a long time. They are very difficult to remove, so it is easier to purchase and install a new corrugated ventilation duct. How to do this, we discussed in detail in the article.

Installing a kitchen hood

If this is a wall-mounted hood, so that the structure looks beautiful and the corrugation is not conspicuous, we close the part of it that is located directly above the hood using a special metal box. Everything is ready! By the way - instead of corrugation, you can use plastic pipes. They look much prettier and don't spoil the look of your kitchen. Where to install the outlet for the hood

Ideally, the socket should be at the same level with the drafting device or slightly higher to avoid rapid wear of the cable. But if you run the cable along the wall and fix it, then the socket can be located, in principle, anywhere (taking into account electrical safety requirements, of course). I would like to remind you that all electrical appliances used in the kitchen must be grounded.

How to connect the hood to ventilation

Separately, I would like to say a few words about connecting the hood to the ventilation window, because this is one of the most important points of work. In order for the whole structure to work effectively and not spoil the appearance of the kitchen, the first thing to do is to purchase a ventilation shield with a hole for the corrugation (or for a plastic duct). At the stage of connecting the corrugation to the ventilation, the first thing we must do is to seal the edges of the corrugation with the flap. For this, you can even use some kind of sealing agent, although, in some cases, the corrugation sits quite tightly without it. If you are using a plastic air duct, then you will not need a sealant at all. After you have connected the air duct, the shield can be planted on the ventilation window. We will fix it there with dowels. If you decide to remove the corrugation from the hood to the window, fixing it there is done according to the same principle, only you need a shield of a different type. However, we would not recommend using a window for an extractor hood, because this may be due to certain inconveniences during the cold season. And it won't look pretty at all. Well, the hood installation is complete. At the end of the work, you need to check how it works.Plug in the plug, press the power button - the motor should start working. Take a piece of paper and bring it to the chimney. If the hood is working properly, the sheet should be sucked into the pipe by the air draft. So, now you also know how to properly install the hood and its elements.

You just have to go to the store and buy a hood

and clamps from that

whichever you like best and whose products meet your expectations of beauty and quality.

Comparison of rigid duct and flexible corrugation for ventilation

Plastic and aluminum corrugations are very popular with users. Polymer air ducts are more expensive than their metal counterparts, but they look prettier in the kitchen. You should know that plastic does not change its shape, like an aluminum corrugation, therefore, before installation, you need to know the exact dimensions of the future structure. Plastic air ducts are more difficult to install, however, they provide a low noise level of the hood operation. In addition, you can choose a corrugation of almost any color that will perfectly match the overall design concept of the kitchen and furniture wall.

Features of the selection and installation of corrugations under the hood

When buying a hood, we purchase an air pipe.

It can be in the form:

- an aluminum corrugated sleeve that can be simply shaped to the desired shape due to its flexibility; the disadvantages of corrugation include noise during operation and inconvenience during washing and cleaning due to the ribbed surface;

- a plastic round duct consisting of convenient polymer pipes; works "quietly", it is easy to clean, but difficult to install;

- a square duct made of plastic - PVC, which differs from a round one only in cross-section.

According to the outlet on the hood, it is determined which pipes, with which section, are suitable. During installation, if necessary, an adapter can be supplied.

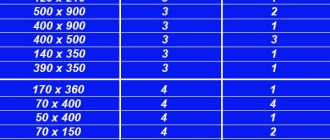

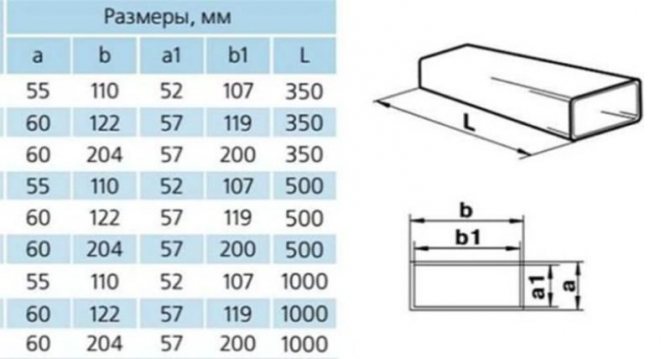

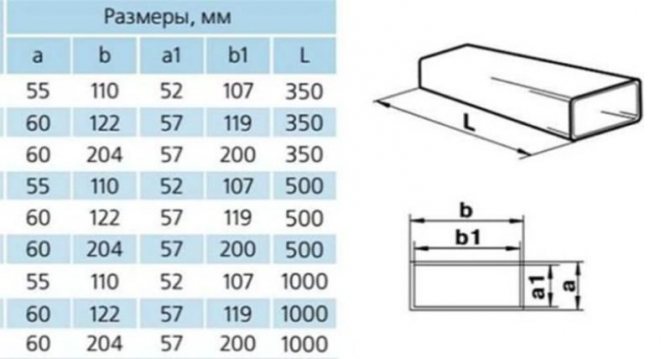

Diameter of round air ducts, including corrugated ones: 150mm, 125mm and 100mm. Flat pipes have different sizes, which can be found in the figure.

PVC flat pipe size chart.

The diameter of the round pipe or corrugation used for the hood is selected according to the size of its outlet. They must match.

It is not advisable to install an adapter on the outlet for attaching a smaller air duct, because of this, the air is not cleaned sufficiently, at a low speed.

Plastic and corrugated air ducts differ in price, corrugation is cheaper.