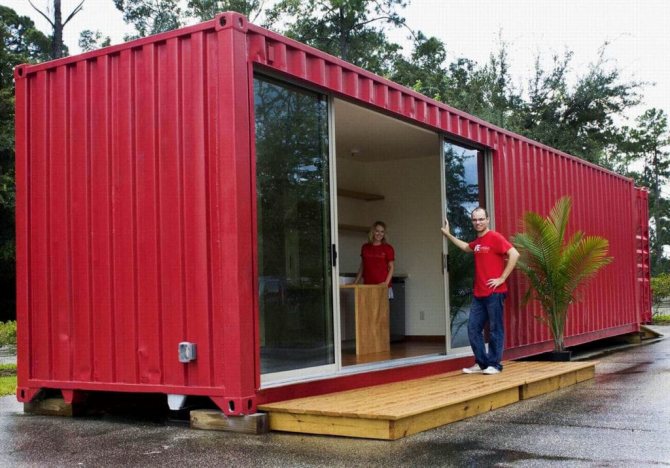

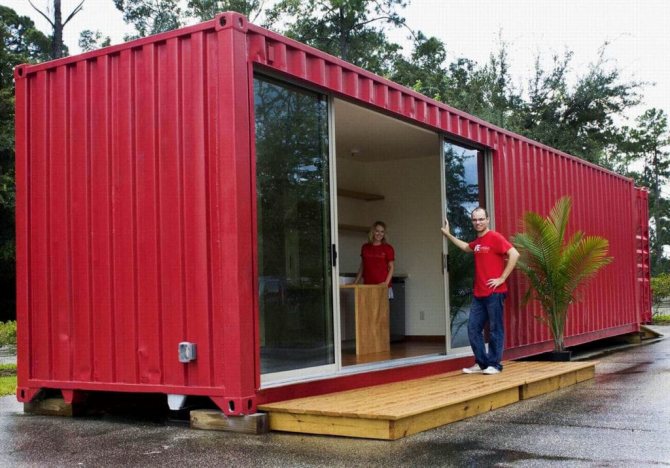

Many people call the insulated container the home of the future. The idea of using all-welded metal structures was adopted due to their ease of transportation over long distances and the possibility of quick installation. Due to their convenient size, they are well suited for a garage, basement, summer cottage, and even for the construction of a residential building.

You can stack modules together, stack on top of each other, connect. To build a home from shipping containers with your own hands on a tight budget, you need to know how you can do it and where you can save money to get the best results. The main job is to insulate the containers inside and outside.

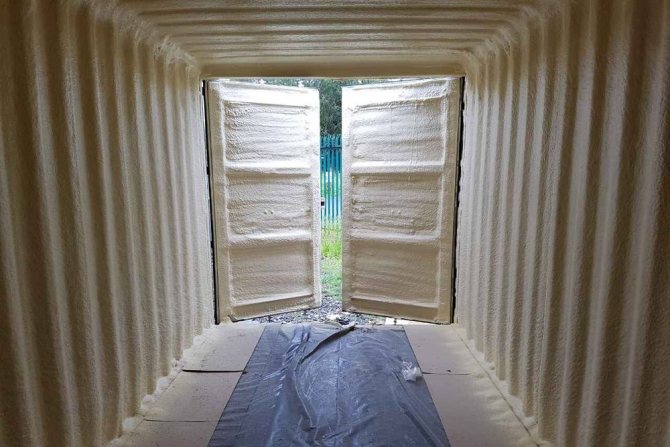

View of a non-insulated container inside

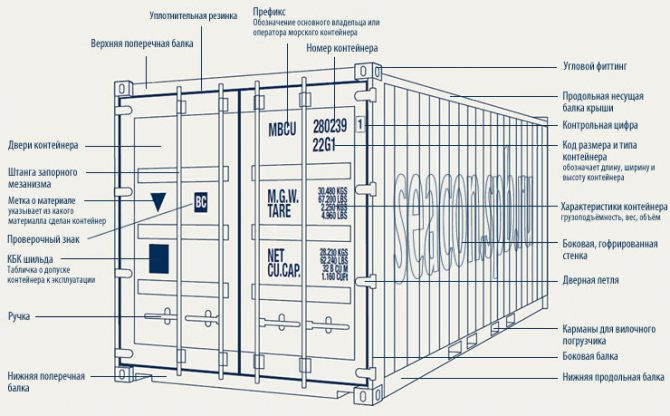

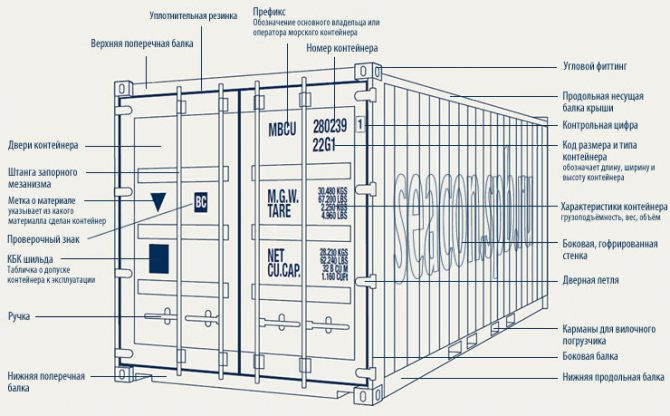

The device of the sea container

Universal large-capacity containers are designed for the transport of goods. Their base consists of a strong and rigid metal frame. The metal thickness ranges from 1.5 - 2.0 mm. On the inside, the metal structure is sheathed with steel anti-corrosion sheets with a corrugated profile, which gives it strength and good rigidity. Such modules can withstand various external influences.

How the sea container works

The container is equipped with hermetically sealed swing doors with handles that open with locking mechanisms. On the outside doors are marked with symbols: weight, volume, carrying capacity and others. If the labels are missing, the container has been repainted. There may be rust underneath the paint.

The weight of a 20-foot container is 2.1 tons, a 40-ton container weighs 3.6 tons.

The containers are not meant to be sheltered. Bare metal conducts heat well, so in order to live in such an iron box, you first need to insulate a sea container for housing, equip ventilation, make windows and doors, sort out floors, and erect a roof. Architects transform ordinary iron boxes into amazing homes and offices. They create custom designs and continually come up with new and improved ideas.

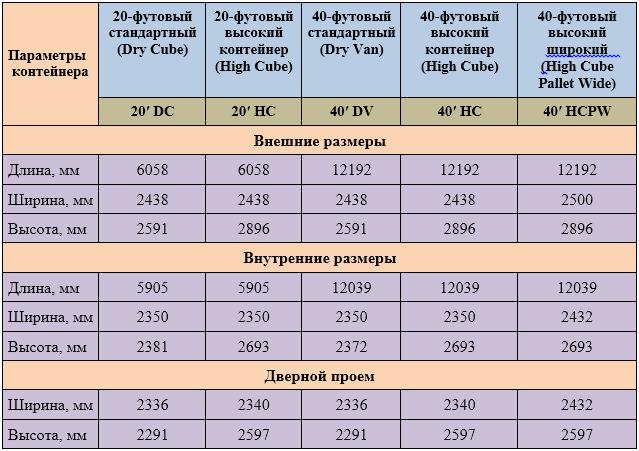

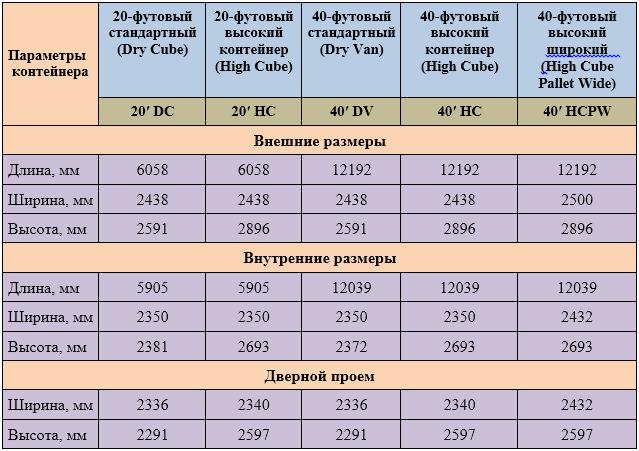

Shipping container size chart

Pros and cons of container houses

The advantages of a house from a container for housing determine the justification for its insulation:

- affordable cost. The price for forty-foot models, on the basis of which you can equip a room with an area of up to 28 sq. m, varies in the region of 68-75 thousand rubles. In Western countries, such used transport containers are used to build hostels, self-sufficient residential buildings with all conveniences;

- installation and re-equipment does not require fabulous investments, often the foundation is not even needed, the main thing is to take care of communications;

- the container does not create any difficulties in transportation, it is easy to deliver it by long-length;

- a universal structure is formed, which, depending on needs, can be adapted for seasonal or permanent residence;

- if you wish, you can implement a mobile project.

The final cost of insulating a sea container depends on the specifics of the materials used for insulation and decoration. When compared with the construction of a house made of sandwich panels or bricks, the cost of arranging the workpiece in question will be 8-10 times lower. Such a budget option can be useful even in a domestic climate, especially if there are restrictions on the timing of the construction of the structure.

The main disadvantage of such projects is the impossibility of building buildings exceeding 3 floors.Someone is confused by the urbanistic look of the building, but such a rectangular shape is easy to beat in fashionable modern styles.

Marine packaging attracts with the breadth of possible applications - from capital housing to sheds for tools. In Europe, you can find everywhere public transport stops from containers, cheap hotels, street eateries. They are also irreplaceable as the basis for residential and administrative wagons, cabins. The reason is that the corrugated steel in the base is not afraid of atmospheric phenomena, is strong and has a long service life.

Containers can be used to make shelter or shed

As cellars, these structures are advisable in conditions of light sandy loam and sandy soils, if you take care of weighting so that the container is not squeezed out to the surface. The lateral pressure of heavy loam is capable of deforming the walls; such a cellar will have insufficient thermal insulation.

How to equip a container for housing

If you purchased a container and decided to make a garage, cellar, living quarters out of it, conduct a thorough inspection before insulating it. If you find any damage, repair it.

The sequence of works on insulation:

- clean rust with sandpaper or grinder;

- weld the holes;

- prime and paint the walls;

- make a crate from a wooden bar 5 cm thick or a metal profile;

- fix it around the perimeter of the walls and ceiling using fasteners for the drywall profile and self-tapping screws;

- Insulate the sea container from the inside by placing the insulation in the grooves between the bars;

- stretch the vapor barrier.

Before insulation, preparatory work is carried out

Do not forget about the support of the house. The container is placed on a timber frame.

Required materials and tools

To insulate a sea container for living, you need to prepare the following materials:

- insulation,

- polyurethane foam,

- paint,

- penofol,

- chipboard or fiberboard sheets,

- sealant,

- wooden beam with a cross section of 5 cm,

- foil tape,

- primer,

- drywall sheets,

- dense plastic wrap.

Some of the tools that may come in handy:

- grinder with petal circles,

- electric drill,

- screwdrivers,

- dowels,

- yardstick,

- screwdriver,

- gun for applying sealant and polyurethane foam,

- brush,

- a hammer,

- self-tapping screws 6.5 cm long,

- sharp knife

- building level,

- a pencil or felt-tip pen for marking.

To insulate the container, you will need a grinder with petal circles

You need to get personal protective equipment - gloves, goggles, a respirator.

How and how to insulate walls and ceilings

If the container is not insulated, it will be stuffy in the house in the heat, and very cold in the cold. In addition, condensation forms on the steel walls, leading to other problems such as corrosion or mold. When deciding which side to insulate, preference is often given to internal thermal insulation, since the appearance of corrugated steel walls in the interior of the house does not look at all.

Retrofitting the containers inside allows for a more traditional interior. When it comes to what type of insulation to use, the following materials are commonly chosen:

- polyurethane foam (PPU);

- mineral wool;

- expanded polystyrene.

The type of insulation and thickness are selected based on the climatic zone and the purpose of the building. How to insulate a container for housing?

Polyurethane foam

PPU spraying protects the metal from corrosion and external noise. For work, cylinders with polyurethane foam are used. There is a cheaper option - two-component foam spraying using special equipment. This material costs less, but the equipment to work with it is very expensive.Therefore, it is better to use the services of builders or rent a tool.

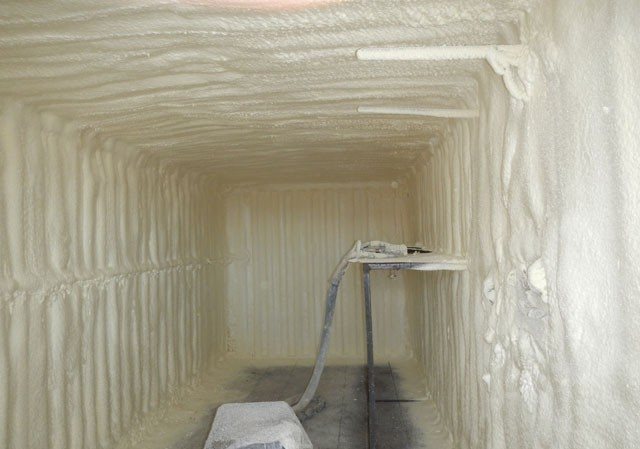

Insulation with polyurethane foam.

Insulation works using PPU are carried out in the following sequence:

- clean the walls and ceiling from dust;

- moisten the surface;

- shake the foam canister for at least one minute;

- turn the can over and spray the foam in a thin layer as it expands after being applied to the surface.

After spraying, a finely porous structure is created, which perfectly insulates the walls and ceiling. Cylinder foam is almost impossible to apply to the ceiling and tops of the walls. Therefore, for their finishing it is better to spray a two-component foam. It provides very high strength and hardens quickly and evenly.

Expanded polystyrene

Expanded polystyrene in slabs is a new generation of foam. It has a higher structure density. Two layers of this material create a seamless vapor barrier, which in turn prevents condensation from forming on the metal walls.

Warming with modern foam

How to insulate a container house with expanded polystyrene plates? For this, during the construction of the lathing, cells are made equal to the width of the foam plate, which is laid in the cells.

Mineral wool

The "cake" of mineral wool insulation is durable and fireproof. Cotton wool has biological and chemical resistance. Metal elements in contact with mineral wool do not corrode. When installing thermal insulation inside the room, a mineral wool insulation is covered with a membrane film.

Mineral wool insulation

This insulation has a low vapor permeability, so all condensate will concentrate in the layers of mineral wool. The film is attached using a construction stapler or expansion anchors.

Advice! If you buy foil mineral wool, you can do without a vapor barrier film.

If you have no experience in insulating living quarters, be sure to watch the video on how to properly insulate a container before starting work. After insulation, the house is ready for sheathing with plasterboard or other materials.

Table of characteristics of materials for thermal insulation of metal containers.

| Name | Properties | Features of insulation |

| Mineral wool | Fungus and mold are not formed in the fibers. | You can hide the wiring in mineral wool. The laying of these materials begins from the walls, and only then the ceiling is insulated. It is imperative to make holes for the condensate outlet. |

| Expanded polystyrene | Has a low thermal conductivity. Has the best ratio: price - quality. | |

| Sprayed polyurethane foam | Durable and resistant to wear and tear; | The insulation layer should be solid. |

Performance

In most cases, expanded polystyrene or mineral wool is used as wall insulation from the inside.

The process of insulating a container with your own hands is as follows:

- The selected insulation is attached to the pre-made frame. It is best to use self-tapping screws for this. In the lower and upper edges of the walls, it is important not to forget to make holes for the condensate to escape.

- After the main work on thermal insulation has been carried out, it is necessary to lay a vapor barrier layer. A reinforcing film is perfect for this.

- After the walls are insulated, it is worth moving on to the ceiling and floor. For this, you can use basalt wool with high density and heat capacity.

Standard technology

Standard technologies are used for any type of container used for cargo transportation. They are also used for heating wagons.

Due to this, it is possible to maintain the required temperature in the room and reduce its sudden changes. You can also increase the protection against mechanical stress.

The standard process for wall cladding with foam from the inside is as follows:

- Walls, ceiling and floor are finished with thick sheets of polystyrene using liquid nails.

- The slots are sealed with polyurethane foam.

- A polyethylene film is stretched over the foam.

- Wall cladding is made with foam sheets.

- New foam sheets are covered with foil again.

How to insulate a floor for a living space

Before insulating the floor, a thick film for vapor barrier is first laid in the container. After its arrangement, logs are installed with a step of at least 0.9 m.Then foam or other high-quality insulating material from the above is laid. If there are gaps, they are filled with polyurethane foam so as not to leave cold bridges. Then the floor is covered with moisture resistant material. It can be plywood, chipboard or fiberboard.

Note! Do not choose cheap mineral wool of dubious quality and from an unverified manufacturer. Usually the reason for the reduction in price is a deviation from the manufacturing technology. Therefore, such a material can quickly lose its thermal insulation properties.

The next stage of floor insulation is the laying of decorative flooring. After that, along the perimeter of the container, the floor is insulated with a sealant or polyurethane foam. At the end of the work, plinths are installed.

How metal wagons and containers are insulated using polyurethane foam

For obvious reasons, such a transport container is insulated only from the inside. Polyurethane foam adheres well to almost any surface, without requiring the use of additional agents - primers, hydro and vapor barrier films.

Insulation is applied directly to the inner surface of the container or car, forming a flat surface without joints, perfectly retaining heat and not creating cold bridges. The material has a low thermal conductivity of 0.020-0.035 W / (m * K), therefore it will not let heat or cold inside.

Is a sea container suitable for arranging a cellar

Many people believe that a metal cellar is unprofitable, it will take a lot of costs to install it, and still iron, even strong, will soon begin to deteriorate due to moisture in the ground. Usually, the conversion of containers into a cellar is common in the southern regions of the country, where there is little rainfall.

For the equipment of the cellar, a pit is first dug out of the sea container. The bottom is covered with a 15 cm layer of gravel or a concrete cushion is created to prevent moisture increase. The insulation of the cellar is done in the same way as for the house. Leave a gap in the upper part and install ventilation.

The optimal result is guaranteed by a combination of external and internal insulation. A well-insulated container inside and out will serve you for a long time. In principle, such a modular building is no different from an ordinary house.

In addition, when insulating with polyurethane foam:

- there is no gap between the surface of the container and the layer of insulation, therefore, rust and mold do not form on the iron;

- a layer is formed that has both steam, hydro and wind insulation properties. This significantly reduces the cost of work and shortens the time it takes

- even a small team will be able to insulate any wagon or several containers in one day;

- an environmentally friendly coating is formed that does not emit an unpleasant odor. No harmful substances and vapors are released from the surface of the polymer layer. This allows the use of insulated wagons and containers for the transport of food products;

- a sealed non-flammable layer is formed, which protects food and goods in the event of an external fire. If a fire source occurs in a neighboring carriage or container, the PPU will not let the fire inside;

- The shipping container becomes stronger, less deformed and lasts longer. A container or carriage with a layer of insulation applied inside will last 30 years or more;

- smoothing of temperature fluctuations with a layer of insulation prevents condensation from falling on the inner surface of the metal;

- low thermal conductivity of the material allows it to be applied in a layer of only 10-15 cm, which makes it possible to maximize the volume of a container or carriage;

- With the help of polyurethane foam, you can insulate a surface of any shape, so there will be no problems with fastening the insulation to the semicircular wagon roof and to the ribs of the container.

Insulation from the inside - possible problems

So, insulation from the inside is possible and sometimes even recommended, especially if we insulate the container. Are there any problems with this method of insulation? The answer is yes! Can they be foreseen, avoided? The answer is yes!

If we talk about possible problems, then there are only two of them:

- When insulating the container from the inside, it is extremely important to make the heat-insulating layer continuous, excluding any, even minor contact of the iron outer walls of the container with the air of the inner volume! The easiest way to realize such a continuous thermal insulation layer is by spraying a layer of polyurethane foam.

- It is necessary to EXCLUDE any cold bridges in the form of materials with high thermal conductivity, connecting the external metal walls with the internal volume of the room through the thermal insulation layer. For example, if you are going to make a metal partition wall inside the container, in no case should it be welded from the inside to the outer walls of the container. The fastening of such elements must be done through a material with a high resistance to heat transfer! For example, in the example described, attach wooden bars to the outer walls, and attach a metal partition to these bars.

Insulation of containers for the carriage of goods

The industry produces initially insulated 40 and 20 feet containers for the transportation of perishable goods. A reusable container without climatic equipment with a foam layer is called an isothermal container.

It looks like a step-by-step instruction for making an isothermal container from a conventional one as follows:

- installation of the battens directly on the enclosing structures;

- cutting expanded polystyrene to the size of the crate cells;

- laying insulation in cells with glue.

Fig. 18 Thermal insulation of the shipping container

For reusable containers, the presence of cold bridges is not critical, it is much more important to save the volume of the working space inside. To increase the service life of the container, foam plastic with a polyethylene film is used.