Circulation pumps designation

In the marking of circulation pumps, after the brand, two numbers are usually indicated.

The first of them indicates the nominal diameter of the supply pipes in millimeters... This figure can be used to judge the connecting thread of the pump. For example, if the nominal diameter of the pump nozzles is 25, then their connecting thread is 1 inch. The correspondence of nominal diameters (D.Y) and thread sizes is indicated below:

- DN 15 - thread 1/2

- DN 20 - thread 3/4

- DN 25 - thread 1

- DN 32 - thread 1 1/4

What do the numbers 25-40, 25-60 32-80 mean in the pump brand

Pump designation Grundfos UPS 25-40 or Compass 25-40 means that the nominal diameter of its branch pipes is 25 mm, which means the connecting thread is 1 inch, this pump is capable of developing a head of up to 4 meters (40 decimeters).

Considering that there are 10 decimeters in 1 meter, conclusions can be drawn about other designations:

- 25-60 - connecting thread 1 inch head 6 meters

- 32-80 - connecting thread 1 1/4 inch head 8 meters

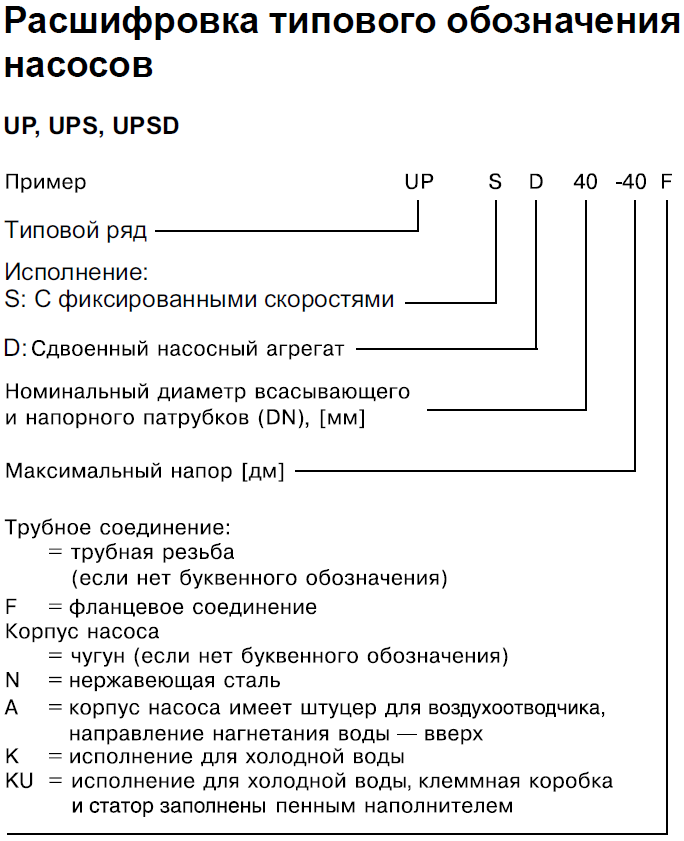

Main marking

Circulation units are usually labeled as UP ?? XX-XX ??, where instead of X there are numbers, and instead of "?" - letters (however, the latter is optional, it all depends on the purpose of the pump). Let's analyze the main marking using the example of UP S D 25-40 F:

- UP - pump type (circulation);

- S - there is a three-speed switch;

- D - paired, that is, two pumps located on opposite sides of the pipeline are simultaneously pumped along one pipe;

- 25 - the diameter of the connection of the pipelines of the system to the pump, expressed in millimeters. The series is available with diameters of 25, 32 and 40 mm.

- 40 - power, expressed in the height of the rise of the liquid column. Height is written in decimetres, that is, to convert to meters, it must be divided by 10: 40 = 4 m;

- F - flanged pipe connection to the pump. If this index is absent, then the pipes are connected using pipe threads.

The main Grundfos marking can also contain information about the material of the pump housing, its design and additional options:

- by default, if there is no letter designation, then the material of the unit is cast iron;

- N - made of stainless steel;

- B - the body is made of bronze;

- A - equipped with an air vent connection;

- K - version for cold water;

- KU - terminal box filled with foam for cold water.

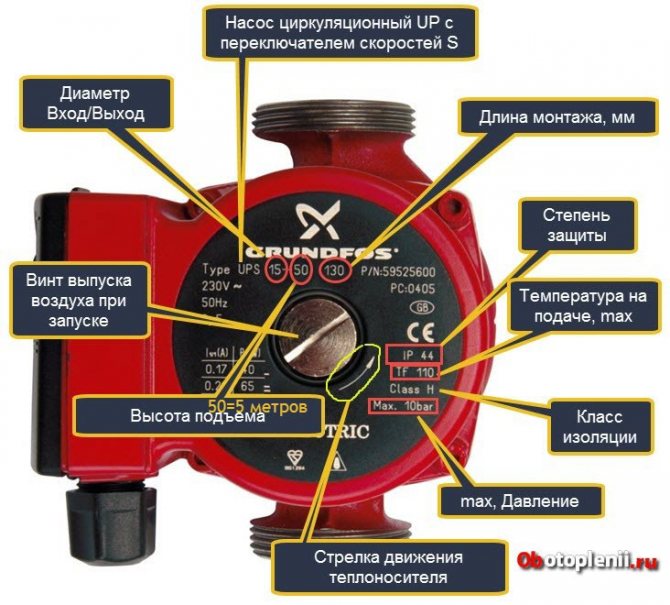

As a rule, the installation length of the circulation pump is 180 mm. However, for installation in confined and narrow spaces, there are options with a reduced installation length of 130 mm. The distance required for installation is written after the main marking.

Electrical characteristics

In addition to the purely technical characteristics of the Grundfos pump, the decoding of the marking of the circulation pumps also allows you to find out the data on the current consumption and the protective design.

At the top left, there is information on the characteristics of the current: 230 V and 50 Hz. The Danish company also manufactures its products under a network with a voltage of 110 V and a current frequency of 60 Hz.

Since the circulation pump has the ability to operate in three modes, for each of them the characteristics of the current and power are presented, summarized in the table. The left column is the amperage consumed in milliamperes, and the right is the power recorded in watts.

It can be seen that the maximum pump power corresponds to the third operating mode. Thus, the main marking indicates the pressure developed by the circulation device at exactly the third speed.

Centrifugal pump designation

In the designation of centrifugal pumps, information is often indicated about the characteristics - the flow rate and head of the pump.

What do the numbers 60/35, 70/50 mean in the pump brand

Jumbo pump designation 60/35 indicates that the nominal flow is 60 l / min and the maximum head is 35 meters.

The Jumbo 70/50 brand indicates that the nominal pump flow is 70 l / min, and the maximum head reaches 50 meters.

With the selection of a circulation pump, sometimes unnecessary questions arise. The owners of heating systems do not suspect that it is very easy to make the right choice. Next, consider which pump to choose for heating in most cases that are found in private houses.

How important is it to choose the right pump

For the heating to work, a certain volume of liquid must move through the pipes. It transfers heat energy from the boiler to the radiators. If the pumping volume is small (weak pump), the boiler will overheat and the radiators will remain cold.

But the reverse is no better. If the pump is too powerful, it will consume excess electricity, which will run up a hefty amount over the years, while the speed of water movement will be unnecessarily high and noise will arise in the radiators, disturbing the residents.

Therefore, when choosing a circulation pump for heating, it is important to get into some kind of middle - all the energy should be taken from the boiler and consumed on radiators, but there should not be too much water speed, since this is very unprofitable.

What happens in the heating system

The circulation pump pumps the heat carrier through the pipes, more often ordinary water. Its impeller creates a small pressure H (head, measured in meters of water column) and sets a certain speed of movement of the liquid. The result is a liquid flow rate through the pump Q (m3 / hour) - the volume that is pumped per unit of time.

Each pipe system has its own hydraulic resistance, which impedes the movement of fluid. If there was no such resistance, then any unit would pump unlimited volumes over an infinite distance…. But in order to push water through the pipes, the pump creates pressure and consumes electricity. Pipes resist the movement of water, as a result, a certain amount of liters per minute (cubic meters per hour) is obtained.

What is important when choosing a pump

The whole trick of choosing a pump for the home is that if the user does not want to understand the performance charts, he can not. And just read how to choose a circulator for your home below ...

For those who want to understand the problem, you can report the following. The main characteristics of this unit are the pressure N, m, created by it, at a certain flow rate Q, m3 / hour.

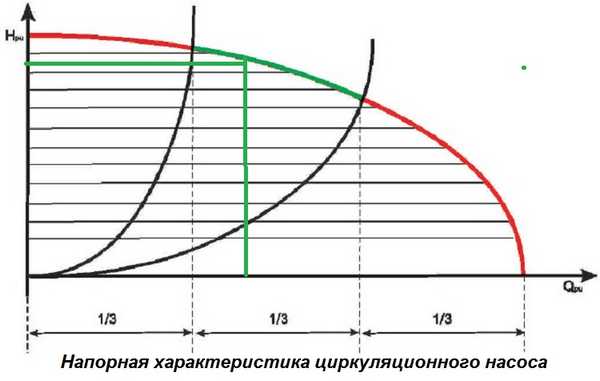

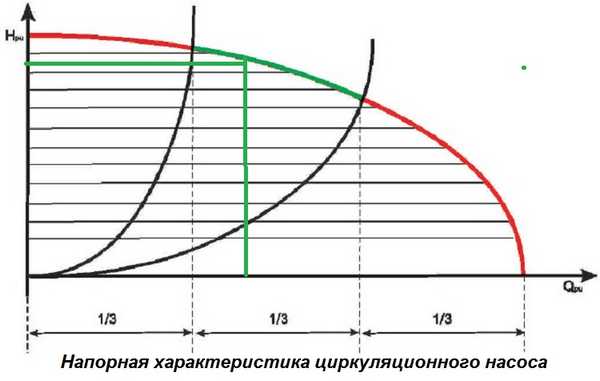

Each circulator has a performance graph. Moreover, they are different for each speed of its work.

The heating network of the house also has a dependence of the flow rate on the pressure. If this graph is superimposed on the characteristics, then they will intersect somewhere, - you get the operating point of the pump. That is how much he will drive the coolant, creating such and such a pressure.

Calculation of pump parameters

Circulation pumps are installed in heating systems. They do not create excessive pressure, but simply push the coolant at a certain speed. Since the demand for heat changes depending on weather conditions, then the speed of movement of the coolant must also change. Therefore, it is better to install variable pumps - three-speed.

Before buying, you should decide on two main parameters: productivity (flow rate) and pressure. If water is the coolant, the pump performance is calculated using the following formula:

Q = 0.86 * Pн / (tpr.t - trev.t)

- Pн - heating circuit power, kW;

- toret.t - temperature of the heating agent in the return

- tpr.t - flow temperature.

If there are several circuits, determine the flow rate for each of them and add it up. The sum of the costs of all circuits will be the required performance of the unit.

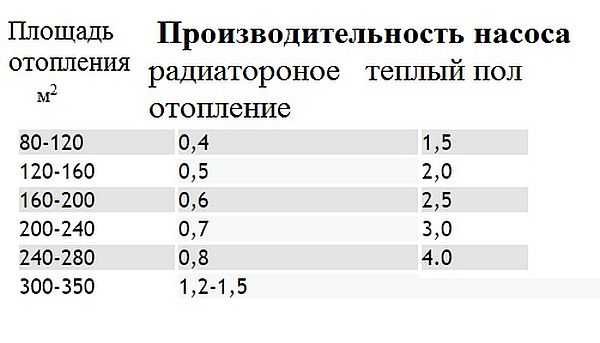

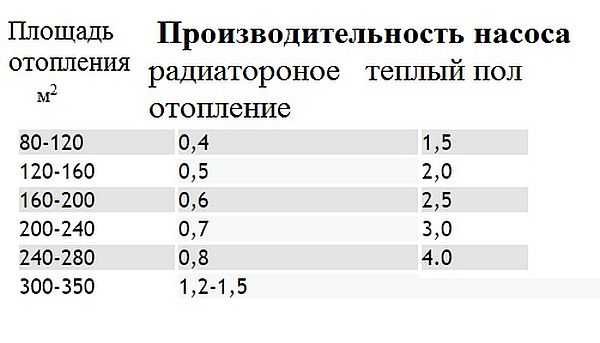

The temperature difference in hot water heating systems is usually 5 ° C, the power of the circuit most often depends on the heated area, therefore, to simplify the selection of a pump for a water underfloor heating, you can use the table. But it should be borne in mind that the calculations were based on the average figures for central Russia. Therefore, if your house does not have the best insulation, or you live much north or south of the middle lane, you will have to correct the result (or calculate it yourself). In general, this parameter is taken with a margin of 15-20% in case of abnormal cold weather.

Table for determining the pump performance depending on the heated area

The second characteristic by which the pump is selected is the pressure that it can create. The head is necessary to overcome the hydraulic resistance of pipes, fittings, and other system components. The system resistance depends on the pipe material and pipe diameter. The value of the hydraulic resistance of the pipe is available in the accompanying documents to them (you can use the averaged data). Also, the calculation takes into account the increase in resistance on the valve (1.7), on the fittings and fittings (1.2) and on the mixing unit (it is necessary when using a high-temperature boiler and the coefficient for it is 1.3).

H = (P * L + ΣK) / (1000),

- H - pump head;

- P - hydraulic resistance of a running meter of a pipe,

- Pa / m; L is the length of the pipes of the longest contour, m;

- K - power reserve factor.

To calculate the required pressure in the circuit, the passport hydraulic resistance of the meter of the pipe is multiplied by the length of the circuit. The value is obtained in kPa (kilopascals). This value is converted into atmospheres (the pump head is measured in atmospheres) 100 kPa = 0.1 atm. The found value, depending on the availability of fittings and valves, is multiplied by the appropriate coefficients. After all the operations, you have found the operating point of the pump.

Choose a model based on the graphical characteristics

But the calculation of the pump for underfloor heating is not over yet. Now you need to select a model. To do this, in the catalog of the manufacturer you like, find the characteristics of the pump. It is presented in the form of a graph. Select the model so that the found operating point is in the middle third of the characteristic. If you install the three-speed option, then select the model according to the second speed - this will ensure the optimal, and not at the limit, operating mode and your pump will serve for a long time and will provide a normal temperature even on cold days.

Advantages of devices

Thanks to the special properties of the Wilo pump, the efficiency of the heating system is significantly increased. In this case, thin pipes can be used, which, in turn, helps to reduce material and fuel costs. Also, when using a pump, the volume of carbon dioxide that is emitted into the atmosphere decreases, and the daily consumption of electrical energy is no more than 250 watts.

Of course, such a device is not cheap. You will have to pay a large amount for its purchase, but the cost will surely pay off later when used due to energy savings and durability. The device will not need repair for a long time.

Vilo pumps have many positive properties.

The most important ones are as follows:

- There is no heat loss after the water has evaporated.

- The system can be controlled automatically. The device has an LCD screen, a built-in thermostat and other elements to allow for control. You can also manually switch the speed of rotation of the working shaft.

- Compared to many circulation pumps from other brands, Wilo devices are quite compact and therefore do not take up much space.

- The motor and rotor have a multi-stage protection system that helps prevent damage due to sudden power surges.

- The motor runs silently, making it possible to install the device in residential buildings.

Wilo pumps are used in small rooms with an area of several hundred square meters. The selection is carried out according to such parameters as power, volume of circulated water, area of the room and head height. The last parameter is the most important.

How to distinguish an original pump from a fake, you can see in the following video:

Types of Wilo pumps

Pumping equipment from Wilo can significantly improve the heat supply process not only on an industrial scale, but also in local heating systems, such as a private household or an apartment.

Now many people know that installing a pump in an individual heating system with natural circulation allows not only to significantly improve the quality of heating, but also to additionally significantly save on the consumption of natural gas or another type of fuel.

Of all the pumps that the manufacturer represents, models designed to work in heating systems are especially in great demand. Let's consider in more detail their types and applications.

Pumps are produced in two types:

- with dry rotor;

- with wet.

What is the fundamental difference?

Dry rotor pumps

The first type of pumps means that the rotor of the electric motor is not in contact with water. The connection of the motor with the working part (body) is made through special sealing rings that do not allow the pumped liquid to get into the electric drive.

It can be said that such a pumping unit consists of two parts: the first part is an electric motor, the second part is a housing equipped with two nozzles - one for discharge, the other for suction, and an impeller is also located in it, which carries out pumping.

These pumps are usually used in systems with long pipe runs and large connection diameters. They are widely used in industrial and heating boiler houses. The warranty period is 3 to 5 years. It depends primarily on the brand and performance.

Equipment indicators:

- High level of efficiency - more than 80%;

- High requirements for the presence of suspended particles in the pumped medium. It is necessary to install filters to prevent foreign objects from entering the unit;

- The room where this equipment is installed should not be dusty. In the presence of dust, the O-rings quickly become unusable. Replacing rings is a labor-intensive process that requires special skills;

- Type of connection with pipelinesusually flanged.

Glandless pumps

This type is most common for household needs. The device of this type of pumps is fundamentally different from that previously considered. The electric motor and impeller are located directly in the housing, which has an inlet and an outlet. Liquid is pumped as if by the rotor itself, which, in turn, is equipped with an impeller (impeller).

Cooling and lubrication of bearings is carried out directly by the pumped liquid. This type of equipment is used in heating systems with a short length and small diameter pipelines. Most often they are connected using a threaded connection.

Equipment indicators:

- Virtually silent operation;

- Has a compact design;

- The ability to change the operating parameters, which allows you to save on electricity consumption;

- Long term of work;

- Virtually maintenance-free.

Wilo products have proven themselves primarily for their energy saving indicators, as well as their high level of quality and durability. Housings are made of gray cast iron or stainless steel, depending on the purpose of the pump. Working shafts - stainless steel only. The bearings are made of graphite.

Glandless pump models for heating systems are equipped with three-mode impeller speed control units. These blocks are controlled manually. The temperature regime in which such units can be operated is from - 20 to +130 degrees Celsius.

This type of equipment is used in heating systems with a short length and small diameter pipelines

Applications

The Wilo brand produces pumps that are designed for different purposes and therefore have different characteristics.

With the help of such a pump, you can water the beds directly from a well, well or the nearest reservoir.

Their area of application is extensive and varied:

- Wilo devices are used in heating systems in closed circuits.

- They are used in the water supply of private houses and in water production wells.

- Such pumps are also suitable for pumping groundwater when creating basements, cellars.

- They are also used on the construction site when working with polluted waters.

- The owners of private suburban areas have found good use for them, in particular, those who are engaged in the cultivation of plants on their personal plot.

The Vilo pump can operate in the most difficult conditions, and it does not matter what temperature the water circulating through the pipes will have and what the pressure will be.

You can connect the device yourself without any problems. For this, it is equipped with special spring terminals. It does not have a fan, so there is practically no noise during operation.

Varieties of circulation pumps

Wilo-branded circulators fall into two categories. Some of them may have a wet rotor, while others, respectively, dry. Those devices that are equipped with a wet rotor can be used in a heating system for a room with an area of 100 to 750 m², while the liquid circulating in the pipes can be heated up to 120 ° C.

In a cold climate, the presence of a heating system is simply necessary for a person to feel comfortable

Main technical characteristics of Wilo pumps:

- The minimum temperature that a heat transfer fluid can have is minus 10 ° C.

- The head height of such devices can be from 2 m to 12 m.

- The speed value ranges from 950 rpm to 4800 rpm. The pumps have three different operating speeds.

- The weight of the equipment also varies. The lightest devices weigh just over 2 kg, while the heaviest can weigh up to 8 kg.

- The working parts of the motor are placed in the coolant, due to which it is lubricated and its operation becomes noiseless.

In rooms with an area of more than 750 m², as well as in heating systems that serve not one, but several buildings at once, another type is used - equipped with a dry rotor. Their rotation speed does not exceed 3 thousand rpm.

Common labeling

When choosing a Wilo brand pump, you should pay attention to the letters and numbers that follow the main part of the name. Each of the letter designations indicates the type of product, and the numbers in the product labeling indicate its most important characteristics.

Drain TMW 32/11

This Wilo pump model is a vortex drainer made of various materials. The device is capable of pumping slightly contaminated water (meaning those with the diameter of pollution particles not exceeding 1 cm).

Brief technical characteristics of the circulation pump fork Drain TMW 32/11:

- The maximum depth at which it can be used is 3 m.

- This device has overheating protection. In 60 minutes of operation, it will be able to pump 15 cubic meters. meters of water.

- As the name implies, the head height of this device is 11 m, the cross section is 165 mm.

Its average cost is 10,500 rubles.