Characteristics of asbestos cement pipes

Anti-advertising to asbestos has done its job. Building materials made on the basis of asbestos components began to leave the market, but this did not affect asbestos-cement pipes.

Because these products have a fairly wide list of advantages, besides, they are also made of white asbestos - chrysotile, which, as scientists have proven, is not dangerous to human health.

The raw material for the production of asbestos-cement pipes is fiber cement mortar, which contains asbestos fibers in the amount of 15-20% of the volume of used Portland cement.

The production of pipes is not very difficult, which affects the cost of production. Therefore, the price for asbestos-cement pipes is several times less than for metal ones.

Installation rules

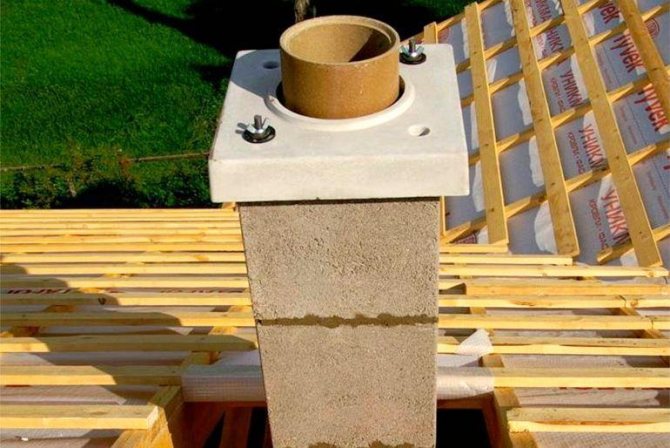

Installation of an asbestos chimney is a relatively simple task, quite doable independently. But during installation work, you should be guided by some rules and tips.

The most important ones are:

- According to the regulations, horizontal sections of the chimney, in the case of using asbestos material, must be completely excluded. With a lateral pipe outlet, a slope must be made in the direction of the boiler at least 3 degrees.

- The higher the chimney is, the more wind load falls on it. Therefore, when installing a pipe on a roof that rises more than two meters above the ridge, roof braces must be used.

- When working through the roof and through the floor slabs, brackets based on asbestos cement should be used. A free distance of at least 10 centimeters must be kept between flammable materials and combustible coatings.

- In buildings made of aerated concrete blocks, it is categorically not recommended to install separately located chimneys. Due to such a misfire, a wall with a chimney fixed on it can simply collapse due to wind load.

Pipe selection

Immediately before installation, the diameter and height of the asbestos-cement chimney should be calculated. You should be guided by the rule that the higher the chimney is located, the more the wind load ultimately affects it.

The calculation of the height is carried out with an orientation to the remoteness of the chimney from the ridge of the building. The diameter is calculated according to the parameter of the volume of the combustion chamber. In most cases, it is recommended to focus on a cross section of at least 120 millimeters.

For domestic and industrial needs, asbestos pipes with dimensions (in diameter) of 100, 150, 200 and 500 millimeters are mass-produced.

Installation and connection to the boiler

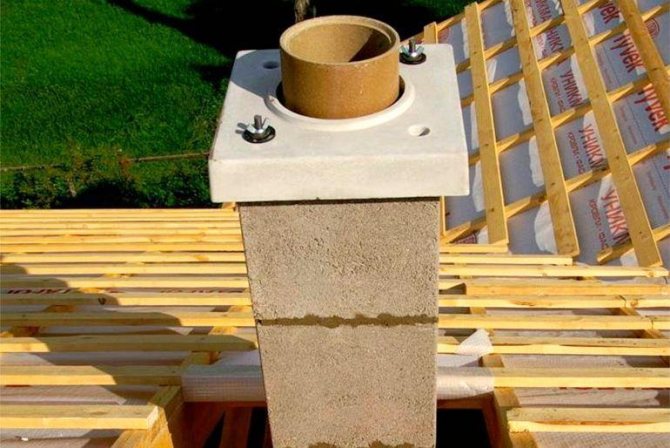

The installation of the flue gas pipeline is carried out in a vertical position, and immediately before installation, make sure that the pipe is free of cracks and defects. The support should be either brick or concrete.

The connection of the pipe to the boiler is carried out using a piece of stainless steel pipe or using an adapter. In the outlet segment of the outlet branch pipe of a furnace or boiler, asbestos material is not used, since there the temperature can jump up to +500 degrees.

When laying an asbestos-cement pipe through ceilings, special penetrations should be used. This is one of the conditions for fire safety. The space between the chimney and the casing is filled with any non-flammable insulation.

Warming: how and how is it done?

It is quite easy to insulate an asbestos chimney. Any material that has a low liquid absorption coefficient can be used as insulation.Basalt wool is best used in most cases.

Warming begins with fixing the heat-insulating material. They should wrap the pipe and then secure with clamps. Knitting wires can be used instead of clamps.

Installation of an asbestos chimney

Next, a protective layer is made, for which a foil-clad heat-insulating material is applied over the primary insulation material. An additional layer of insulation protects the basalt or other material from the ingress of liquid and additionally provides protection against fire.

Next, the installation of a metal frame is carried out to protect the insulated chimney or its outer part, which passes through the roof. Also, instead of a frame, sandwich systems can be used, equipping the outer layer of stainless steel, and the inner layer of asbestos material.

The consequences of asbestos pipes in the chimney (video)

Use as a liner

Although this option is possible, it is categorically not recommended and is practically not used. It is much easier and more profitable to use stainless steel pipes for such purposes. It is even more effective to use polymer liners, but they are too expensive in terms of cost.

If you stop choosing, nevertheless, installation on asbestos pipes should be done from top to bottom. After the rehabilitation procedure, it is necessary to make the facing of the outer parts of the pipes with bricks. In general, an asbestos-cement pipe with a brick lining as a sleeve is a very bad and unsafe option.

Advantages and disadvantages of asbestos-cement pipes

Sufficiently stringent standards are applied to any pipe material, which determine the quality of the product. Therefore, the advantages of asbestos-cement pipes include:

- Long-term operation, where manufacturers give a guaranteed service life of 25 years.

- They perfectly cope with low temperatures, so their laying in the ground at a shallow depth does not reduce their technical and operational characteristics.

- It can withstand temperatures above +115 C.

- Smooth inner surface that does not allow sludge to settle on it, similar to plastic pipes.

- The hydraulic resistance is very low.

- Corrosion resistant.

- Loyalty to almost all chemically active substances is absolute inertness.

- Simplicity of the installation process, where an asbestos-cement coupling is used to connect individual pipes and sections.

- A small specific weight of products, therefore, when laying pipes of small diameter, there is no need to use special equipment, the installation can be done by hand.

- Wide range of sizes.

- Acceptable price.

Of the shortcomings, only one point can be distinguished. According to the established standards, it is impossible to use asbestos-cement pipes for laying water pipes in residential buildings, hospitals, children's institutions.

They can only be used for water supply with industrial water. It should be noted that today in Europe, asbestos-cement pipes are used for laying gas pipelines. This type of pipe found its main application in the laying of cable products as a protective tunnel that ensures the safe operation of cables and wires.

Features of the operation of chimneys from an asbestos-cement pipe

One of the main difficulties in using asbestos-cement pipes is the need for timely soot removal. Due to the fact that only one inspection hole is installed in such a chimney, it is difficult to clean the pipes, therefore, first of all, it is worth doing prevention.

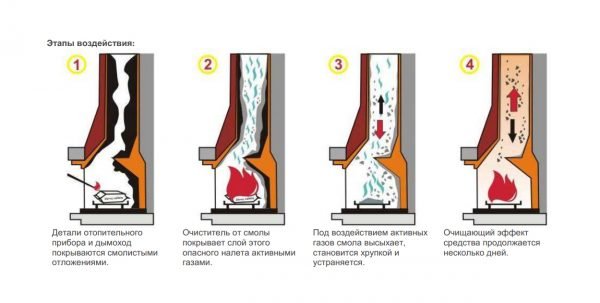

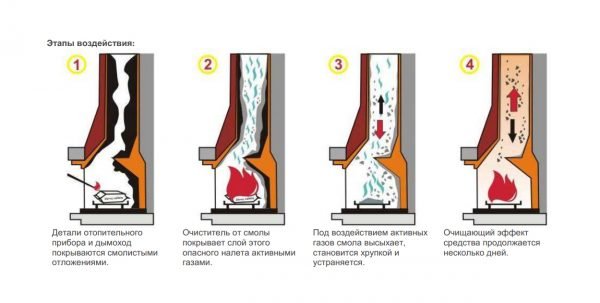

Chimney chemical cleaning

Under the brands Hansa (Lithuania), Spalsadz (Poland), "Chimney sweep" (Russia) produce cleaning agents in the form of a powder (a mixture of copper chloride, phosphates, ammonium salts, etc.). When 1-2 measured spoons of the composition are poured onto burning wood, the chemicals react with slag and soot on the walls of the chimney.The catalyst converts pollutants into flammable gases and solids. The gaseous component leaves the chimney with smoke, the rest of the particles fall into the furnace and are cleaned out together with the ash. Manufacturers recommend using the product every 4-5 lights to keep the pipes clean. The effect of the drug is easy to notice by the emitted whitish smoke. A product with the same effect is also available in the form of a log soaked in the necessary chemicals.

The action of the chemical chimney cleaner is very simple.

Users confirm that this method of cleaning and prevention is very effective and greatly simplifies life in the absence of inspection hatches in the chimney.

But given that asbestos-cement pipes are sensitive to temperature rise, the use of anti-soot powder should be used with caution. If the manufacturer does not indicate the dosage for such a chimney, it is better to start with half of the standard portion.

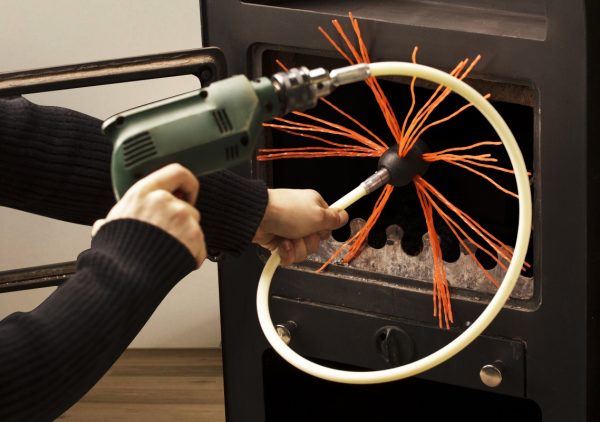

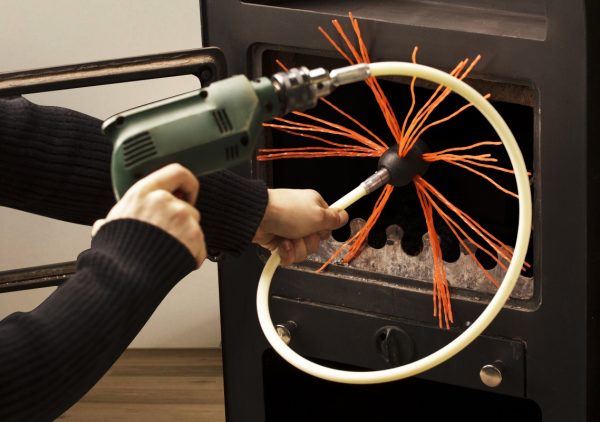

Mechanical chimney cleaning

Manual soot removal is carried out using round brushes and long-handled scrapers. It is best to select them with a diameter slightly larger than that of the pipe, and with a pile of metal wires. Since the inner surface of asbestos-cement chimneys is initially rough, and soot can sink deeply, cleaning with plastic brushes will not bring the desired result.

If the roof of the building is very high, there is a reason to entrust the cleaning to professionals.

Brushes can be placed on rods or rods, but even the longest handles do not allow you to clean a 5-meter chimney efficiently. Therefore, they can only be used for partial cleaning of the pipe in the accessible area. But if a convenient inspection hatch is equipped, you can scrape out the chimney first from the bottom and then from the top.

A wire rope with a brush and weights can also be used to clean long pipes. Its end with a cleaning tip is lowered from above and, under the influence of gravity, sinks to the very foundation of the chimney. Since chimney ducts made of asbestos-cement pipes are always mounted strictly vertically, almost all the dirt can be removed in 1-2 passes.

Rotary chimney cleaning method

The rotary method is a type of mechanical cleaning. It is based on the same scraper brush on a long flexible rod, only the holder itself can be connected to a drill or a powerful screwdriver. The mechanism will provide such high brush revolutions that cannot be provided manually. Therefore, cleaning is performed much faster and better. Rotary cleaning kits like TORNADO are easy to find on sale, but some craftsmen make similar devices on their own.

For rotary cleaning, you can make the device yourself

If cleaning the chimney is not difficult for you, the rest of the asbestos-cement pipes will not bring much trouble.

Scope of asbestos-cement pipes

Some areas where you can use asbestos-cement works have already been said, but this is just a small part. They are used by:

- Drainage sewerage. Manufacturers currently offer asbestos-cement perforated products, with the help of which subsoil water and precipitation are collected and removed from suburban areas.

- Sewerage systems: pressure and non-pressure. This is especially true of the pressure sewage system, because asbestos-cement pipes can withstand pressures up to 15 atm. Therefore, there is no need to install cast iron or steel pipes, which are several times more expensive than asbestos-cement pipes.

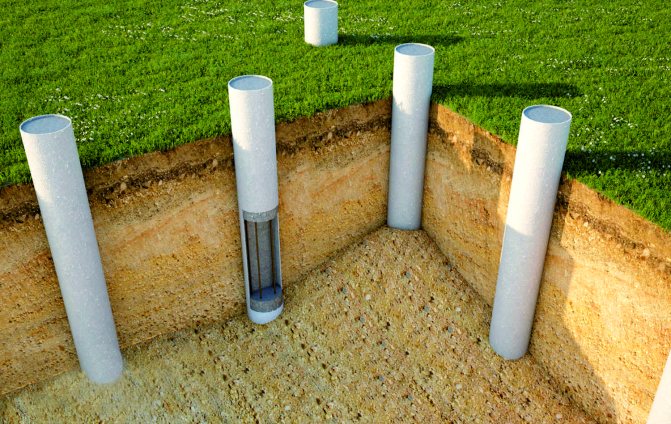

- Casing construction when drilling wells and finishing wells.

- The regulations allow the construction of garbage chutes in apartment buildings. This reduces building construction costs.

- Low thermal conductivity and large thickness of asbestos pipes make it possible to use them in chimney structures.At the same time, fire safety requirements are met one hundred percent.

- They are used for the construction of fences and various protective structures as pillars.

- Permanent formwork is made of them for pouring columnar foundations and supporting pillars for floors.

- Designers also pay attention to asbestos-cement pipes. They make flowerpots, flower beds, decorative racks and so on. Fortunately, these products are easy to process, and this is another plus of them.

Nuances when installing an asbestos pipe for a chimney

It is possible to smooth out the shortcomings of asbestos-cement pipes if they are installed correctly.

It is necessary to pay attention to many parameters: the properties of the heat carrier, the distance from the heater to the pipe, the diameter and its length, the properties of the insulating materials.

Wood or coal cannot be used as a heat carrier with such a chimney. Sometimes such a chimney is built in baths, but an adapter must be installed. The greater the distance from the heating structure to the pipe, the lower the temperature inside.

Therefore, the more heat the coolant gives off, the longer the adapter is needed. It is recommended to install a chimney made of several materials, with asbestos cement being the farthest from the boiler.

Another parameter is reliable insulation and insulation. They protect the chimney and the surrounding materials from condensation. The fact is that asbestos itself has a good waterproofing ability, but the condensate does not consist of pure water. Such a pipe really does not let water through. Condensate, on the other hand, has impurities of salts, acids and metals, which easily penetrate into the pores of the pipe and spread to other parts of the chimney.

In addition to internal condensation, it is necessary to protect the pipe from external moisture. For this, in addition to insulation and insulation, special umbrellas are used, which are attached to the head of the pipe.

Classification of asbestos-cement pipes

The production of asbestos products is regulated by GOST 539-80 (pressure) and GOST 1839-80 (non-pressure), in which it is determined that asbestos-cement pipes can be produced with a diameter of 100 mm to 500 mm, and their length has 2 standard sizes: 3.95 and 5 m.

Pressure

Asbestos-cement pressure pipes are classified according to the pressure acting on them passing through the medium. They are divided into 4 classes:

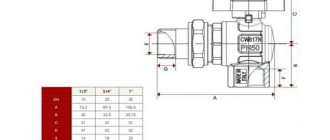

- VT6 - withstand pressure up to 6 kgf / cm², this is practically 6 atm. To connect such products, a CAM6 coupling is used.

- VT9 - they hold a pressure of 9 atm, a coupling of the CAM9 brand is used.

- VT12 - 12 atm, CAM12 coupling.

- VT15 - 15 atm, CAM15 coupling.

The indicated pressure is the maximum provided that there is no external pressure on the pipeline.

Asbestos-cement pressure pipes are divided into 3 more types, which are based on the inner diameter and length of the product. We will not analyze all the proposed options, we will consider only one with a nominal bore of 200 mm, which will show the difference.

First type:

| Asbestos-cement pipe brand | Inner diameter, mm | Wall thickness, mm | Length, m |

| VT6 | 196 | 14 | 3,95 |

| VT9 | 189 | 17,5 | 3,95 |

| VT12 | 181 | 21,5 | 3,95 |

| VT15 | – | – | – |

Second type:

| Asbestos-cement pipe brand | Inner diameter, mm | Wall thickness, mm | Length, m |

| VT6 | 200 | 12 | 5,0 |

| VT9 | 196 | 14 | 5,0 |

| VT12 | 188 | 18 | 5,0 |

| VT15 | 180 | 22 | 5,0 |

Third type:

| Asbestos-cement pipe brand | Inner diameter, mm | Wall thickness, mm | Length, m |

| VT6 | 196 | 14 | 5,95 |

| VT9 | 189 | 17,5 | 5,95 |

| VT12 | 181 | 21,5 | 5,95 |

| VT15 | 176 | 24 | 5,95 |

It should be noted that the pressure options have a turned chamfer to fit into the coupling. It is smaller in outer diameter. The length of the chamfer should not be less than 20 cm.

Free-flow

This type of pipe does not have a landing chamfer, i.e. they are purely straight. As in the previous case, asbestos products are divided by size. However, the range is not that large.

- Conditional passage: 100; 150; 200; 300 and 400 mm.

- Wall thickness, respectively: 9; ten; eleven; 14 and 17 mm.

- Length: the first two diameters have two indicators: 2.95 and 3.95 m, the last three have only 3.95 m.

How to fasten asbestos pipes

Hello! We bought a house outside the city and encountered strong condensation from the chimneys of a gas boiler. The boiler is low-temperature. The same story is with asbestos ventilation pipes. It turned out that the former owner had grown these pipes with galvanized pipes. From a distance (3-storey building), they looked like completely asbestos-cement. During the replacement of the roof, this was revealed. Now we want to supply asbestos-cement instead of galvanized pipes, but on the basis of slate, we were told that the industry does not produce either clamps or couplings for non-pressure pipes, and those that are produced for pressure pipes are not suitable, because they have rubber gaskets inside, which are not suitable for chimneys. And without gaskets, the couplings will be too loose and there will be no good connection. Tell me, some way out: how to properly connect two asbestos free-flow pipes? And where can you get it? Asbestos pipe shells?

Elena, Voronezh.

Hello Elena from Voronezh!

On the Internet, find the phones of the sales department of the Bryansk plant of asbestos-cement products (located in the city of Fokino, Bryansk region). Call and specify the range of asbestos-cement couplings produced by him of the required diameter.

If they don't tell you anything comforting, then there are possible options for using asbestos-cement pipes in which one of the ends has an extension into which the usual end of the asbestos-cement pipe is inserted. Since there will still be a small backlash between the inner surface of a pipe with expansion and the outer surface of a pipe with a conventional end, it is usually filled with corded asbestos, an asbestos-cement fabric. Or they are sealed with an ordinary mortar (cement-sand with a proportion of 1 part of cement - three parts of sand).

Another option is that two asbestos-cement pipes are joined together. On one of the pipes, a shell is preliminarily put on, which has a significantly larger inner diameter than the outer diameter of the asbestos-cement pipe, a plaster or masonry mesh is inserted into the gap (rigidity and the size of the cells of the average parameters).

To prevent the mesh from slipping down, it is fixed in any possible way (usually with a soft wire). The pipes and shell are centered (create their alignment). Then they are carefully filled with the same cement mortar mentioned above. From below, make a temporary miniature formwork from boards, plywood, and other materials. The task of the formwork is to prevent the mortar from falling down.

As a shell, you can then take the most suitable coupling for pressure asbestos-cement pipes, remove the rubber gaskets and perform the indicated manipulations.

Hard? No, not really, it is quite within the power of an ordinary person to do it.

Semyonich (author of materials)

Installation of asbestos-cement pipes

The main criterion for the strength of an asbestos-cement pipe is the asbestos fibers that are distributed along the pipe structure. This peculiar reinforcing frame creates a strong and reliable material structure.

That is why shaped products (fittings) are not made of asbestos cement, except for the coupling, which repeats the shape of the pipe. In fact, this is a pipe segment. The thing is that asbestos fibers will be located chaotically in the fittings, and this is a decrease in strength several times.

Therefore, when assembling pipelines in a straight circuit, it is the connecting sleeve that is used. If it becomes necessary to branch the pipeline at different angles or to connect an additional line, then in this case, fittings made of metals are used.

So, a coupling made of asbestos cement is a pipe segment in which grooves are made from the inside on each side. A rubber seal is placed in them.The cross-section of the seal is not round, but complex, which makes it possible to carry out the maximum sealing of the butt joints. Therefore, seals are often referred to as cuffs.

Installation of the pipe into the coupling is not difficult. It is necessary to insert the coupling into the pipe with little effort or vice versa. In this case, it is recommended to leave a small radial gap of 3 °, which will ensure the bending of the connected pipe during elastic deformations.

For example, when the ground moves. By the way, this technology of the installation process with the installation of a gap makes it possible to do without the use of temperature compensators. If large-diameter pipes are connected to each other, then the coupling is installed using special devices.

How to do it right:

- A sleeve is placed in a trench near the first pipe.

- Rubber cuffs are inserted into it.

- The coupling is put on the pipe and, with the help of levers and jacks, is pulled onto the latter until it stops.

- The second pipe is laid next to it so that its end is pressed against the end of the coupling.

- Now the sleeve is moved back to the end of the second pipe using the same tools and devices. It is important not to overdo it here, therefore, accurately determine the possibility of movement, so as not to weaken the tightness of the structure.

It is very important that the connected elements are on the same axis, this is a guarantee of the quality of the final result. Be sure to keep an eye on the cuffs so that they do not twist or shift.

There is another option for connecting asbestos-cement pipes, where a polyethylene coupling is used. The latter is heated before installation, put on one of the pipes until it stops, which is located inside the connecting element.

Then a second pipe is inserted from the other side. If the coupling has cooled down before installing the second element of the pipeline, then part of it can be reheated. When it cools, the polyethylene shrinks, the coupling decreases in size, which leads to its tight fit on the outer surfaces of the connected parts of the pipeline.

Non-pressure asbestos-cement pipes, which are used as protection for cable networks laid in wet soils, are connected in a different way.

- For this, holes with a diameter of 2 cm are drilled in the coupling on both sides. In this case, there should be two holes on each side, located on opposite sides of the diameter.

- A tarred rag or tape is wound around the pipes.

- The coupling is pulled over one pipe.

- Then the second is installed next to it, onto which the connecting element is shifted in reverse order.

- The resinous materials are compacted.

- Now it is necessary to pour liquid hot bitumen into the drilled holes, while it is poured into the upper hole, and the lower one is controlled. As soon as bitumen flows out of it, it means that the cavity between the coupling and the pipe is completely filled.

Insulation of asbestos-cement pipes for the chimney

Since asbestos is a porous material, soot deposits quickly accumulate on the inner walls of the chimney. Temperature changes lead to the appearance of condensation, which, together with soot, leads to the destruction of the chimney.

Thermal insulation of pipes helps to prevent such consequences. The easiest and most inexpensive way is to use roll materials.

It is important to provide waterproofing. For this purpose, the most suitable would be the use of foamed polyethylene, which is fixed with wire or metal staples.

Heat-resistant heaters are installed outside. Additional brickwork helps to increase the effectiveness of thermal insulation. A metal cover can be installed. It is put on an asbestos-cement pipe, which is insulated with mineral wool. This requires:

- from stainless steel (approx. 2 mm thick) make an outer thermowell with a diameter 10 cm larger than the pipe;

- place an insulating material between the channel and the sleeve;

- ensure good insulation of the joints.

Foil materials are used for thermal insulation of the chimney.

Thermal insulation is also arranged with special cinder blocks. A box is made of them around the channel at a distance of 5-10 cm. The resulting space can be filled with slag, mineral wool or expanded clay.

Repair of asbestos-cement pipes

In principle, their technology is exactly the same as that of their cast iron counterparts. The easiest option is to apply a rubber band, which is secured with wire or clamps. You can also use a bandage soaked in a cement mixture for this. True, you will have to wait until the pad dries out.

If the place of the defect is responsible or material moves under pressure inside the pipeline, then the best option is to dismantle part of the pipeline and install a new section. Fortunately, asbestos-cement pipes are easy to process. You can cut them, for example, with an ordinary hacksaw for metal.

As you can see, asbestos-cement pipes have not yet surrendered their positions. This is especially true in areas where it is necessary to take into account stringent fire safety requirements. We add that these products are by far the cheapest option with decent technical characteristics.

Spheres of application of asbestos-cement pipes, new items with high performance characteristics. Video:

Source: otrubah.com

Types of pipes

Asbestos-cement pipes are used in a wide variety of construction areas, performing different tasks. Two main types of products are distinguished in accordance with the ability to withstand large loads of water - the liquid can flow by gravity or under pressure, which suggests completely different parameters. In accordance with this factor, free-flow and pressure pipes are distinguished, they can also be ventilation pipes used for the construction of fences, chimneys, etc.

Free-flow

They are widely used in modern construction. They have a low specific gravity, corrosion resistance, inability to withstand high and low temperatures for a long time. They can accumulate various substances in contact with their surface, they are not afraid of stray currents.

Installation requires a minimum of time and effort, there is no need to lay additional thermal insulation. Pipelines are resistant to fire, shock waves, and when exposed to water, they can increase the level of strength.

Pressure

The pressure type is used where there is a large water pressure. Usually, sewers, water pipes, heating mains are installed from them. They are also relevant for the implementation of ventilation systems and collectors; you can make a chimney for a stove out of them.

Requirements for pressure pipes:

- Tapering ends

- Passing studies to determine the ability to withstand a certain pressure, water permeability

- The presence of appropriate couplings, thanks to which it is possible to create a quick-release and durable connection

Subtypes of asbestos-cement products

Asbestos-cement pipes can be of other types, in accordance with their purpose. So, chimney systems are often made from brands that are resistant to high temperatures. There are asbestos-cement products for arranging garbage chutes, drains, foundations, ventilation, cable installation, etc.

Pipes for fences have a long service life, are used as boundary columns, to which any lattice material is attached with clamps. Asbestos-cement pipes can be used as casing pipes - for casing wells or in the process of erecting pile foundations.

When choosing, it is imperative to take into account the requirements and features of operation, since elements made of asbestos cement do not imply versatility and those that are used for installing sewage systems are not suitable for a chimney, for example.

Free-flow asbestos pipe

The product is manufactured using a special technology, taking into account standard sizes. The fields of application of free-flow asbestos pipes are different. They are widely used in carrying out gravity sewage without the possibility of building a pressure sewage system.

At the same time, the cost of the construction is much reduced. For manholes, cut asbestos rings are an excellent option.

They are also used as a waste chute. It is important to note that asbestos pipes do not pollute the environment, because the material is resistant to microorganisms. If the pipeline is turned off for a long time and the effluent stagnates, there is no possibility that the soil can be infected through the pipes.

Non-pressure asbestos pipes are widely used as a mine when carrying out various types of communications - telephone lines, electric cables, because they do not conduct electricity. For the same reason, they are not subject to electrochemical corrosion caused by stray currents.

Polyethylene couplings designed for connecting pipelines are easy to install, providing strength and reliability of fastening. Some varieties are used to create heating mains in various systems.

They are an economical way to transport heat, as they have very low thermal conductivity, thereby minimizing heat losses. In such a system, inexpensive hydrophobized gravel is used as a heat insulator, with which the pipes are filled, and additionally covered with a polymeric material in the form of a film.

Non-pressure asbestos pipes are excellent for the installation of heating, plumbing, ventilation, chimneys, storm sewers, where large-diameter pipes are used as a water collector, and smaller pipes are used as drainage drains.

The use of free-flow asbestos pipes in the arrangement of the drainage system

Non-pressure asbestos pipes are used to create a closed drainage system. Installation is carried out taking into account the following aspects:

- Pipes intended for drainage must have openings for free penetration of water.

- As a rule, drainage pipelines are located at a slope towards the water flow.

- To install the system, you need to dig a trench manually or with the help of special equipment.

- In the drainage system, pipes with a diameter of 1-2 cm are usually installed, but in cases where high performance is needed, it is allowed to install products with a diameter of 3-4 cm.

- The products are also installed as wells serving the drainage system. The pipeline can be installed quite deep underground, as its walls withstand the effects of the environment and do not require regular maintenance.

The service life of asbestos-cement pipes is about 30 years.

Options for insulation of asbestos pipes

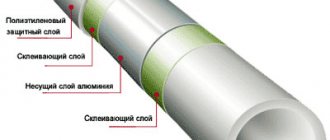

Insulation or insulation is a collection of those materials that are located between the asbestos pipe and the brick. This layer protects the pipe from adverse environmental factors, and the materials surrounding the pipe from condensation. There are several options for insulation:

- With the help of basalt wool and foil. It's simple: cotton wool is wrapped around and secured with clamps. Then the cotton wool is insulated with foil-clad polyethylene. The latter protects the entire structure from water. This option is simple, but less reliable.

- This option is also called "sandwich". For its construction, a steel pipe is required, with a diameter of 10 cm larger than the asbestos-cement one. The steel pipe is placed outside the asbestos pipe, and the space between them is filled with basalt wool or other non-combustible insulation. In the area of the pipe head, the structure is insulated with cement.

We recommend that you familiarize yourself with: What is polyurethane foam (polyurethane foam) pipes and where are they used?

Then the pipe with insulation is attached to the brick structure for the chimney.It is important that the asbestos-cement pipe protrude several centimeters from the brick structure. The more pipe is left outside, the less time the chimney will last.

Asbestos pressure pipe

The pressurized version has a straight, clearly cylindrical or bell-shaped shape. The product is produced in standard formats. The production of such products is carried out strictly in accordance with established standards.

The process takes place in stages and with the obligatory holding of products in special steaming chambers in order to increase their strength by 70-75% in comparison with the original properties. Asbestos pressure pipes have a high degree of strength and durability. They also have low hydraulic resistance.

They are used in the construction of a gas pipeline, pressure water supply, sewage, pressure irrigation and other similar systems. In addition, they are used to create wells, wells, agricultural feeders, overlapping structures, and even as decor in household use.

Asbestos pressure pipes are fixed to each other with heat-resistant couplings and rubber seals. Due to the self-sealing ability of the coupling under the influence of pressure in the pipeline, absolute tightness of the joints is ensured. The absence of weak welded joints is another plus of these products.

Connection of asbestos pipes by means of a cast-iron coupling "Zibo"

Couplings "Gibot" (or "Jabot"), made of gray cast iron, are rather complex devices consisting of two flanges, tightening bolts, a mounting sleeve and two sealing rubber rings.

This type of couplings for joining asbestos-cement pipes does not imply high processing accuracy of their end sections, which is a significant plus. This advantage is especially noticeable in those situations when it is necessary to cut the asbestos pipe into separate sections for installation or repair purposes.

The connection of asbestos-cement pipes by means of Zibo couplings is carried out as follows:

- The pipes are laid on the bottom of the trench dug for this.

- One of the flanges, a mounting sleeve and one of the sealing rubber rings are put on the end section of the first pipe.

- Similarly, another flange and a rubber O-ring are put on the second pipe.

- The pipes are centered, placing them along the same axis.

- The flanges are tightened and fastened with bolts.

The advantages of this method were mentioned above, but if we talk about its disadvantages, then the most significant of them is the susceptibility of tie bolts to the corrosion process, which may lead to their destruction in the future with violation of the integrity of the structure.

Advantages and Disadvantages of Asbestos Pipes

Asbestos-cement pipes have several advantages. They are quite easy to install, reliable and sturdy, are not exposed to aggressive environmental influences and can be located deep underground without the need for replacement.

In addition to these properties, they have a relatively long service life than metal pipes. For example, metal products that do not have resistance to corrosion have already been in need of repair measures for 5-10 years, because formations arise under the influence of corrosion and the inner diameter narrows, which causes a decrease in the pressure of the water circulating through the pipes, and also reduce the rate of heat.

Periodic cleaning does not solve the problem, because the rust accumulated on the walls inside the pipes is not removed and after a while again affects the throughput of the system, reducing the water pressure.

Asbestos modification does a very good job of dealing with this problem. Over time, it becomes stronger and stronger. This is due to the ability of asbestos not to corrode in the aquatic environment and to become stronger due to the hydration of Portland cement.

In addition, the inner surface of asbestos pipes is not subject to overgrowth under the influence of water flow, therefore the initial water pressure is maintained for many years.

So, asbestos pipes have the following advantages:

- absolute inertness to the adverse effects of corrosion, including corrosion as a result of stray currents, since asbestos is a dielectric;

- a wide range of all kinds of sizes and a relatively low cost;

- high temperature resistance - products can withstand temperatures up to 2000C;

- slight linear expansion when heated;

- incombustibility, asbestos pipes are fireproof;

- frost resistance, when the water passing through the pipes freezes, the products are not damaged;

- simple machining and easy assembly with couplings;

- insignificant hydraulic resistance due to the smoothness of the inner walls;

- lack of overgrowth, due to which asbestos pipes retain the throughput of the system throughout the entire operation.

However, in addition to all the advantages of asbestos pipes, there are also some disadvantages:

- their use is not allowed in systems where there is a temperature above 3000C, under the influence of such a high temperature, pipes may crack;

- when using asbestos pipes as a chimney that removes combustion products, they become covered with soot from the inside and absorb condensate;

- as a result of the low thermal conductivity of asbestos, a low chimney draft is formed;

- asbestos products are quite fragile, so you should be extremely careful when transporting them, as well as during installation. In addition, measures should be taken to provide additional protection against soil subsidence, which can lead to unwanted fractures;

- asbestos products have low sand resistance. In this case, plastic pipes are an excellent option in comparison with asbestos and ceramic products.

Therefore, if the presence of sand prevails in the ground, the use of asbestos pipes is not recommended.

Subtleties and features of installation

A sufficiently large number of operational drawbacks and installation requirements limit the possibility of using asbestos-cement pipes for chimneys. Whether it is possible to eliminate shortcomings in work and reduce the risk of fire depends on the methods for designing flue systems and the use of modern auxiliary materials.

Asbestos chimney pipes burst at high temperatures. For this reason, they are not used in the initial sections of the gas outlet, where the temperature is maximum. It is unacceptable to install pipes in a mine that removes the combustion products of devices operating on solid fuels.

Note! The combustion temperature of coal and wood is much higher than that of natural gas, therefore, it is forbidden to equip coal-fired units with chimneys from asbestos-cement pipes.

Asbestos flues are porous and absorb condensation. This quickly leads to their destruction. Therefore, such pipes should be well insulated when exiting through the attic and the roof.

To prevent the formation of condensation, the asbestos-cement chimney should be insulated

Installation process of asbestos pipes

Installation of systems from asbestos-cement pipes is not difficult, but at the same time provides maximum reliability. The connection is made using couplings with rubber rings, which ensure a tight fit and strong joints.

Couplings and rubber rings have a unique self-sealing ability due to the pressure of water passing through the pipes. During the installation of thermal systems, a channelless laying method is used, compensators are not used.

For the installation of tees, bends, valves on the heating system, metal pipes are used, which are connected to the asbestos pipe using a coupling, and the length and diameter of the flowing part of the coupling must strictly coincide with the same parameters for the asbestos pipe. Thanks to the laying of asbestos pipes, it is possible to ensure the complete tightness of the system.

Installation of asbestos pipes is carried out in the following stages:

- First, the parts to be connected are lubricated with a special substance based on glycerin and graphite - this facilitates the installation of the coupling.

- Ditching is carried out in advance according to the specified parameters manually or with the help of special equipment.

- The parameters of the ditch (length and depth) are determined in advance at the design stage of the system.

- Couplings are installed on the pipes, after which it is lowered into the ditch.

- After that, another product is lowered into the ditch without a coupling.

- Next, the coupling is installed on the third pipe and lowered into the ditch, and so on.

As you can see, asbestos pipes have both positive and negative qualities, however, according to scientific studies, it is better not to use products for transporting drinking water, because it has not yet been precisely proven whether asbestos fibers penetrate into drinking water and their negative effects on the human body. ...

Source: oborudovanie1.ru

Layout of pipes along the trench before installation is carried out at a distance of at least 1 m from its edge. Pipes with a diameter of up to 150 mm are allowed to be laid out on the track in stacks up to 1 m high, spaced from each other at a distance of no more than 100 m. Couplings are also laid out in stacks. Pipes of large diameters are delivered directly to the place of laying and laid out on the trench berm in such a way that during pipe-laying work there is no need for additional movements along the trench.

Installation of pressure pipelines for a working pressure of up to 0.6 MPa is carried out using double-edged asbestos-cement couplings with their sealing with rubber O-rings, and for a pressure of up to 0.9 MPa using the same couplings and rubber rings or cast-iron flange couplings with rubber rings. When installing asbestos-cement pressure pipelines for a pressure of up to 1.2 MPa, the pipes are connected only on cast-iron flange couplings with rubber rings.

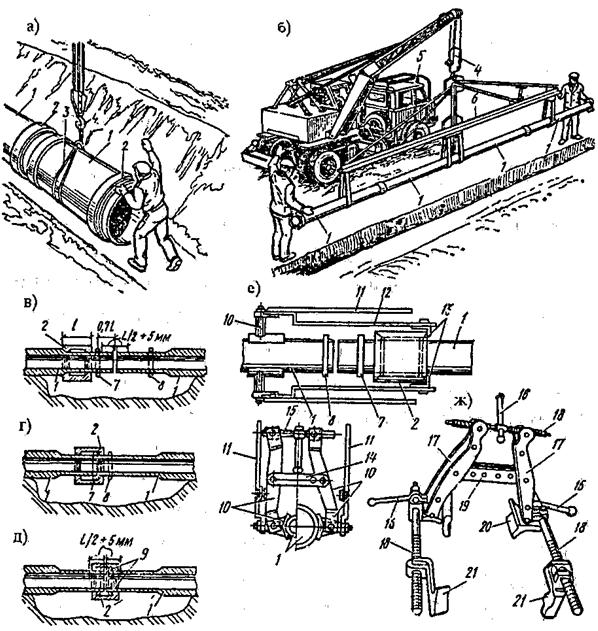

Installation of pipelines from pipes of small diameters

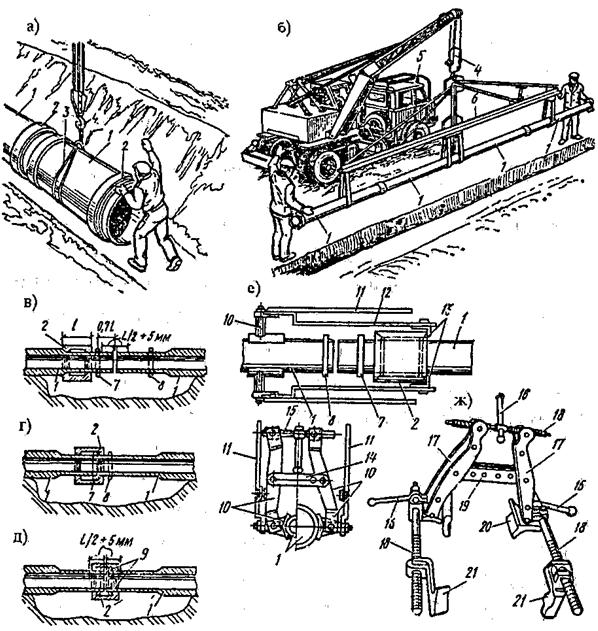

(up to 150 mm) are carried out mainly by hand with lowering them, as well as connecting parts to the bottom of the trench without any devices, if its depth does not exceed 3 m.With deeper trenches with fasteners, the pipes are lowered using a rope or a soft cable threaded into the pipe. Pipes with a diameter of 200 ... 300 mm are transferred from stacks and lowered to the bottom of a shallow trench with straps, and with a trench depth of more than 3 m and fastenings - with the help of a rope or a soft cable threaded through the pipe. Pipes with a diameter of more than 300 mm are laid as close as possible to the edge of the trench, after which they are rolled up to the edge and lowered using automobile or pneumatic cranes (Figure 6.9, a). In order to speed up the installation of pipes of small and medium diameters, before laying, they are enlarged into sections of several pieces (up to four), and then lowered into the trench by a crane using special traverses (Figure 6.9, b), excluding the possibility of breaking the tightness of the coupling butt joints.

Installation of pipelines on asbestos-cement double-edged couplings with rubber O-rings is performed in the following sequence. First, a sleeve and a rubber ring are put on the end of the previously laid pipe, and a second rubber ring is put on the end of the pipe to be laid. The sleeve is put on so that its wider edge (with a working beveled shoulder) faces the joint. After the coupling and the rubber ring are put on, the pipe to be laid is brought close to the previously laid one (Fig. 6.9, a) and they are centered.The centered pipes are fixed with a powder of soil in the middle part, and then at the ends of the pipes with chalk, the places for installing the rings are marked before and after the installation of the joint (Figure 6.9, c). The installation of the couplings is carried out using special devices - a lever jack (see Fig. 6.9, e) or, if more force is needed, a screw jack and a screw tensioner (see Fig. 6.9, g). The main stages of installation of a pipe coupling are shown in Fig. 6.9, c ... e. The correct position of the rubber rings after mounting the coupling is checked with a template or a ruler. The rings should be located behind the working shoulder.

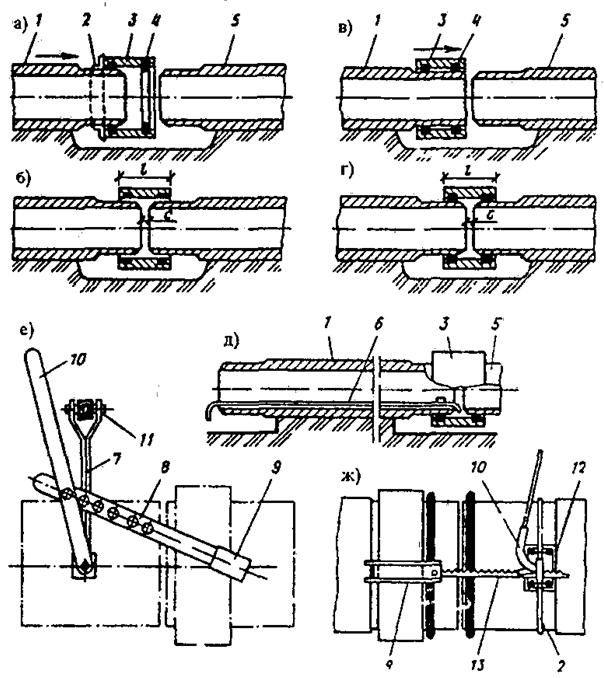

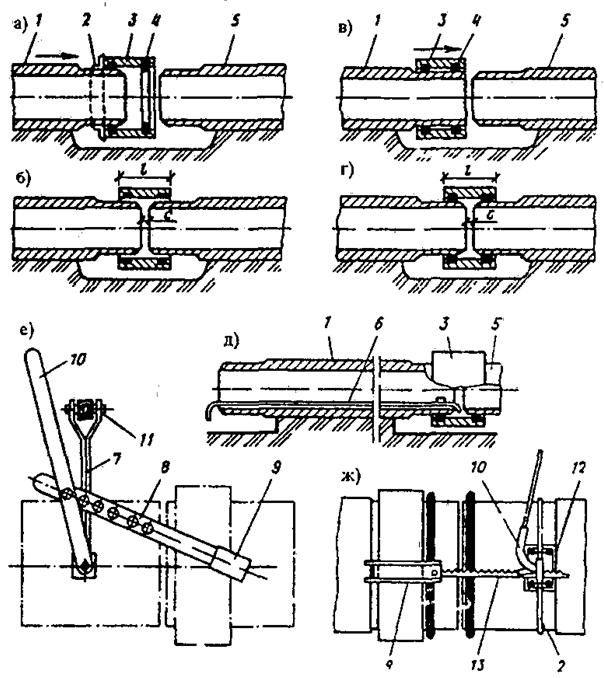

Installation of pipelines on asbestos-cement couplings CAM

with rubber self-sealing rings of figured section has recently become widespread. Installation of pipes on CAM couplings is carried out in two ways. At the first (Figure 6.10, a, b), the sleeve is pushed onto the pipe to be laid to the mark made on this pipe at a distance (

l

-c) / 2 from the end of the pipe, where

l

- the length of the coupling, c - the size of the gap between the pipes (Fig. 6.10, a), after which, using the mounting device, the pipe together with the coupling is pushed towards the laid pipeline until the end of the last laid pipe enters the coupling to a depth (

l

-c) / 2 (Fig. 6.10, b). In order to prevent the coupling from moving during installation, a persistent (portable) clamp is installed at its end. In the second method (Fig. 6.10, c, d), the coupling is pushed onto the pipe to be laid along its entire length (Fig. 6.10, c), and then the pipe is centered with the previously laid and with the help of the mounting device, the coupling of the pipe to be laid is moved to the installed pipe to the existing one on her marks (

l

-c) / 2 (Fig. 6.10, d). With these two methods of installation, the sleeve can be initially put on and on the laid pipe. To ensure the required clearance between the pipes to be connected, a portable rod (Fig. 6.10, d) is used, which is removed from the pipe after the joint is installed. For the installation of butt joints of asbestos-cement pipes, along with the one shown in Fig. 6.10, with a screw jack, a lever jack (Figure 6.10, e) and a lever-and-rack device (Figure 6.10, g) are also used. In order to mechanize this process, special devices are also used, which are replaceable attachments for a single-bucket excavator or a tractor, which capture and lower pipes with a diameter of 300 ... 500 mm into a trench, as well as docking them using CAM couplings.

Fig. 6.9 - Methods of installation of pipelines from asbestos-cement pipes

a - installation of individual pipes, b - installation of sections of several pipes with a crane using a special traverse, c, d, e - stages of installation of a pipe coupling (c - marking of the joint and the initial position of the first rubber ring, d - an intermediate stage of installation and initial position second ring, d - joint in the assembled state), e - lever tensioning jack, w - screw jack; 1 - pipes, 2 - double-edged sleeve, 3 - sling, 4 - crane hook, 5 - crane, 6 - traverse with soft towels, 7 - first rubber ring, 8 - second ring, 9 - cement mortar, 10 - frame with clamp, 11 - levers, 12 - rods, 13 - grips, 14 - spacer bar, 15 - tightening screw, 16 - handle, 17 - body, 18 - screws, 19 - bar, 20 - clamps, 21 - feet

Fig. 6.10 - Installation of asbestos-cement pipes on CAM couplings with rubber self-sealing rings

1 - pipe to be laid, 2 - thrust clamp, 3 - CAM coupling, 4 - rubber ring, 5 - laid pipeline, 6 - portable bar, 7 - body, 8 - pull rod, 9 - grip, 10 - lever, 11 - clamping screw , 12 - thrust shoe, 13 - rail

Installation of pipelines on cast-iron couplings with rubber rings of circular and trapezoidal cross-section is carried out in compliance with the rules for the design of flange connections, i.e. by gradually tightening the nuts located at the ends of mutually perpendicular diameters so that the flanges do not skew.After marking, one flange, one rubber ring and a coupling sleeve are put on the laid asbestos-cement pipe. Before laying the next pipe, a flange and a rubber ring are also put on it, and then after laying it on the bottom of the trench, they proceed to the assembly of the joint. The degree of rubber compaction is adjusted by tightening the bolts while tightening the nuts in the prescribed manner.

Installation of free-flow pipelines is carried out using free-flow asbestos-cement pipes and cylindrical couplings. In this case, first, a cylindrical sleeve is put on the previously laid pipe, having previously made a marking of its actual position after assembling the joint, at each of the ends of the pipes to be connected. The pipe to be laid is lowered into the trench and moved to the already laid one, leaving a gap, as in the case of double-edged couplings, after which it is centered and verified against the sight-glass, cord and plumb line. Further, a split wooden template is installed at the end of this pipe, on which a sleeve is put on so that its middle is above the joint, and the template goes into the sleeve at half its length. A hemp resin strand is placed in the gap between the coupling and the previously laid pipe and compacted with caulkers. The rest of the joint gap is sealed with asbestos-cement mortar. After sealing half of the joint, remove the template and seal the second half of the joint from the side of the newly laid pipe. When laying free-flow pipelines on cylindrical couplings, the pipes are connected with embedding with asphalt mastic or cement mortar without embossing, but to obtain a joint of increased strength, the cement or asbestos-cement mortar is stamped.

Application of asbestos cement pipe

To solve the problems of modern construction, it is simply impossible to do without asbestos-cement products. With their help, the installation of water supply systems for drinking and technical purposes and sewage systems of pressure and non-pressure type takes place.

However, the use of asbestos-cement products goes beyond pipeline setup. They are indispensable for the device of land reclamation, drainage, when laying cables, as well as for the construction of storm drains. Their characteristics make it possible to use the product for casing wells, wells, construction of garbage chutes.

The use of the material is regulated by SNiP 41-01-2003, which states that an asbestos-cement pipe can be used for the construction of chimneys. In Western countries, it has found its place in heat supply systems and gas pipelines. In such conditions, asbestos structures have been successfully working for several decades. The material is popularly used in the nuclear and rocket industry.

Asbestos-cement pipe connection technology

Asbestos cement is a durable refractory material that combines the properties of asbestos and cement. Asbestos, or as it is also called, rock flax, is a group of materials of the silicate class that look like thin, strong threads.

These threads are used as a frame in which other building materials are poured or laid. In the case of asbestos cement, such a building material is cement.

Asbestos gives strength to materials and protects them from fire. There are two types of asbestos: chrysotile and amphibole. The first is widespread in Russia, where there are deposits of asbestos.

This material has been used in construction for about five decades. Amphibole asbestos used to be widespread in European countries, but now it has been banned due to its negative impact on human health.

Asbestos-cement pipes are intended for those structures where there is water, steam or gas. They are able to withstand temperature fluctuations and, when properly installed, will last for many years.

Chrysotile cement and ceramic products

Chrysotile cement pipelines are a type of asbestos products. Their production started quite recently.The difference between the two types of materials is that chrysotile is as safe as possible for health and the environment.

Amphibole asbestos, which until recently was used for sewage, can cause cancer.

It is classified as a carcinogen, since after entering the body, it remains in it for a long time, since it is excreted from it extremely slowly.

Installation of the pipeline between each other involves cutting the line. Sawing results in a saw, which makes the product harmful. It is strongly recommended to use a respirator when handling the material.

It is because of the pathogenicity of the effect of amphibole on the body that chrysotope is used today. The way the pipe is marked indicates that chrysotile cement products have greater strength. For example, BNT-100 is suitable for systems with low load, and BNT 150 is versatile and can be used in any systems.

Types of asbestos-cement pipes

Asbestos-cement products are divided, depending on their purpose, into:

- gas pipelines;

- plumbing;

- sewer.

Depending on the mode of operation, the design is:

- pressure head;

- free-flow.

Pressure and non-pressure BNT products are regulated in accordance with GOST 539-80, GOST 1839-80, GOST 11310-90. The pressure pipe has a diameter on the inner side from 50 mm to 600 mm.

It can withstand pressures ranging from 6 to 9 atmospheres. The pressure pipe is characterized by wear resistance and low hydraulic resistance, which makes it suitable for solving construction problems.

A pressure pipe is used when setting up a pressure water and gas pipeline, as well as for arranging irrigation and drainage systems. It is suitable for arranging wells, as well as overlapping buildings for household purposes.

Non-pressure asbestos-cement pipes or BNT are produced in sections from 2.95 m to 5 m. The inner diameter can be in the range from 50 to 500 mm.

BNT are suitable for setting up non-pressure engineering structures: sewerage, air duct, etc. They are characterized by exhibiting high electrical resistance.

The material of BNT products is not afraid of corrosion. BNT products are used as supports when laying fences, as well as other fences.

Disadvantages of asbestos pipes

Despite the popularity in private construction, the chimney from this material has a lot of disadvantages.

Defects appear almost immediately or after a while, depending on factors such as the fuel used, climatic conditions and the frequency of use of the boiler.

The quality of the pipeline installation is also important. Consider the typical disadvantages of asbestos-cement chimneys and the reasons for their occurrence.

Burnout and burst

Initially, the products were designed for mass production for use in land reclamation, sewer construction and low pressure gas pipelines. The designers did not provide for their operation at high temperatures. The emphasis was placed on tightness and ease of installation of the lines.

The basis of the material is cement, which is a porous material. It absorbs creosote, which is a combustible material. With strong heating, the process of its combustion begins, as a result of which the structure of the walls changes, they become thinner and burn out.

What temperature the pipes made of asbestos cement can withstand: their limit is + 300 ºС.

With further heating, the pressure of the air trapped in the walls of the purlins increases. Products crack, burst and even explode.

Service difficulties

The high strength of asbestos cement is a myth that many people want to believe. Working with links requires extra care and accuracy. The absence of steel reinforcement makes them extremely brittle and brittle, regardless of diameter and type. And that's not all ...

Chimney maintenance is associated with the following difficulties:

- the need for regular cleaning, since the pipes literally attract soot;

- the inability to make inspection windows to get to hard-to-reach areas;

- sensitivity of products to shocks and loads;

- frequent replacement of insulation that collapses from chemically aggressive condensate.

Humidification of the pipeline is fraught with unpleasant consequences, both for communications and for the building as a whole.

Condensate

The main purpose of the products was the laying of open and underground water pipelines of various lengths. Asbestos-cement pipes are resistant to water, but quickly deteriorate when in contact with reactive liquids. It is they that form on the surface of the chimney during the interaction of soot and condensed water.

Aggressive mortar flows down to the roof and is absorbed into its surface. The result is the appearance of stains, unpleasant odors and cracks. Watching the video below will help you assess the extent of the destruction caused by condensation. This issue can be solved with the help of competently carried out insulation.

Product specifications and manufacturing

In practice, asbestos cement is fiber concrete. Its production includes the following stages:

- crushing of asbestos raw materials obtained from mining enterprises;

- fluffing up asbestos with further cutting of fibers;

- adding water to the ratio of cement to asbestos 85:15;

- removal of the resulting pulp on a drum with a mesh structure;

- winding the film on a rolling pin to give the product the required wall thickness.

The production of products takes place only under strict control in accordance with GOST. The weight of an asbestos-cement pipe per 1 m is from 6 to 11 kg. For example, the weight of 300 mm products is less than 500 mm.

The pressure pipe is available in lengths of 3.95 or 5 meters. Its flow area has the following dimensions: 100, 150, 200, 250, 300, 400 and 500 mm. Product weight varies from 45 kg for a 100 mm product to 67 kg for a 150 mm product or 19 kg for a 300 mm product.

Products with a small diameter of 100 and 150 are more suitable for arranging wells or garbage chutes. Low weight allows their installation in a private household. Pipes with a diameter of 300 and more have significant weight, and they are used for laying industrial pipelines.

As with other products, the standpipe 300 is watertight. The diameter of 300 mm allows quick and cheap installation of the system.

Non-pressure products are produced in lengths of 3.95 m, the diameter of which ranges from 100 to 200 mm. BNT 100 has a weight of 24 kg. Products 150 have a weight of 37 kg. The free-flow asbestos-cement pipe 200, whose weight does not exceed 64 kg, provides a clean water supply through the pipeline, therefore its installation is popular in the economic sphere.

Scope of products

With the participation of non-pressure asbestos cement structures that meet technical standards, the following works are carried out:

- External networks of free-flow sewerage are being laid.

- Irrigation systems and channels for laying communication cables are being arranged.

- Vaulted foundations are created (the BNT 100-200 pipe is reinforced and filled with concrete mortar before that).

- Pile foundations are being installed. In this case, pipes BNT 150-500 are used (the diameter depends on the weight of the material from which the walls are erected).

- Chimneys are made (asbestos-cement material is used when the temperature of the exhaust gases does not exceed 3000 ° C).

- Various elements of landscaping are being created - flower beds, pillars, flowerpots, columns, decorative elements of fences.

- Gutters are constructed from sawn asbestos-cement cylinders.

Installation of asbestos-cement pipelines

Asbestos-cement pipes are mounted according to some rules, including:

- Before installation, the outer diameter of the ends of each pipe should be turned to fit the dimensions and obtain a rough surface.

- The connection of the segments to each other is carried out using couplings. It is possible to qualitatively connect the products with the help of grooves applied to the coupling. Thanks to the rubber rings that are installed in the grooves, it is possible to make the most tight connection.

- The radial clearance applied to the connection of the coupling with the pipeline is responsible for compensating for elastic deformation during operation.

- Due to the presence of a gap between the ends, the connection can do without temperature compensators.

- When heated, the product lengthens only by 0.4 mm over a 5-meter length, which is 12 times lower than the elongation of a steel analogue.

- To ensure a tight connection, select a sleeve with an outside diameter that matches the line size.

Source: trubypro.ru

How are asbestos-cement pipes installed?

Next, we will highlight the most important points that have a direct impact on the process of installing pipelines from asbestos cement.

- In order to obtain the required parameters and the required roughness, the diameters of asbestos-cement pipes are grinded. When connecting such structures, special couplings are used. Please note that grooves with elastic rubber rings with a complex glow that resemble cuffs are located on the inner surface of the structures. This allows you to get a reliable and integral system. The place of joining with the coupling is provided for the presence of a radial gap, which provides elastic deformation of the rubber seal. The presence of an installation gap allows you to get rid of the use of temperature compensators. It should also be noted that the coefficient of thermal elongation of asbestos cement is 12 times lower coefficient of steel.

Build safe asbestos-cement pipelines!

Asbestos and asbestos-cement pipes for chimneys were very popular in our country during the Soviet years. This was due to a number of reasons.

Firstly, the country had an excellent raw material base for the production of such products. Secondly, pipes made of these materials were of low cost and high profitability. Thirdly, they had good technical characteristics and did not need insulation and additional insulation.