The need for sealing

Sealing sewer pipes, like sealing all water pipes, is a very essential step in the pipeline installation process. It is especially important to properly seal the joints.

To prevent the pipeline from leaking, since the appearance of unpleasant odors in an apartment or a private house depends on this, it is necessary to choose the right seal for the sewer pipes.

This means knowing which sealant is best for sealing plastic, polypropylene, cast iron, steel, and other products. And you also need to have information on how to seal the threaded connections of the water supply, coupling, flange.

You need to familiarize yourself with other materials necessary for the repair or installation of heating systems, gas supply, repair of sewerage systems intended for draining acids and alkalis, other systems, so that, if necessary, do such work with your own hands.

How to seal any pipe - now in order and in more detail.

Winding flax onto ecoplastic

When working with this material, extreme care must be taken, since it, like brass, can burst. With this in mind, you do not need to be very zealous when twisting.

Before carrying out work, connect both fittings and count the number of revolutions. After that, they must be disconnected back and you can begin to uniformly wind the flax. Upon completion of the winding, the surface of the tow needs to be treated with additional compounds, and only after this can the fittings be connected.

If, for example, 6 revolutions were counted during the preliminary screwing, then after winding the flax it is better to make half a turn less and not to tighten as much as possible. In such a situation, it is more optimal to use packaging paste instead of a sealant.

Role of sealing

If external defects of the pipes can be easily corrected, then in order to seal the pipe connection during operation, it will be necessary to completely suspend the functioning of the sewer system.

That is, re-sealing cast-iron sewer pipes, or risers with hot water, is the same as starting to re-install the pipeline system. Therefore, the appearance of leaks inside the water supply system should be avoided (for example, so that ground water does not get into the pipeline).

It is equally important that there are no slightest leaks from the inside of the sewer system, since this is fraught with the appearance of not only unpleasant odors, but a possible destructive effect on the walls of wet secretions from the pipe.

Materials. What is the name of the thread for sealing pipes?

3.1. List of materials used

Sealing of pipe joints or sockets is carried out using:

- self-adhesive tape (regular and foil type);

- silicone sealants;

- anaerobic sealants;

- gels, pastes;

- epoxy resin;

- sulfur for technical purposes;

- bituminous mastic;

- winding record;

- fluoroplastic sealing material, etc.

Effective means are rubber seal (especially for standard sewer pipes) and pipe seal with linen (tow with solutions made on the basis of red lead and drying oil or Portland cement). The latter is used for sealing large diameter sockets.

Another very important tool often used by plumbers is plumbing thread (or, as it is also called, thread for sealing pipes).

3.2. Self-adhesive tapes

The agent is one of the newest in the field of use for sealing pipe joints.

It differs:

- good anti-corrosion properties;

- high quality sealing;

- efficiency in use;

- ease of use;

- long service life, since they are made on a high-strength polyethylene base;

- breadth of application.

With the help of self-adhesive tape, you can qualitatively carry out not only the sealing of the sewer pipe, but also apply it when installing plugs, turning corners, bends, couplings, valves, and other elements of pipe fittings.

When carrying out sealing, you should adhere to the following algorithm:

- prepare the surface. To do this, it is necessary to clean it of dirt, wipe it dry well;

- when winding the film on the joint, it is necessary to maintain it in a constant tension, in order to avoid possible folds, irregularities;

- it is necessary to wind the material in a spiral manner with an overlap, approximately half its width in order to ensure that the entire surface necessary for insulation is under two layers of material.

Important! Self-adhesive tape is UV-resistant. In order to ensure a long service life, it is recommended to wind 1-2 more protective layers of another material over the tape.

A primer is used to treat certain types of films. It will exclude the minimum impact on the tape of air, moisture, including precipitation. Such measures contribute to a significant extension of the life of the sealing material.

3.3. Silicone based sealants

Any rubber-based silicone sealant is available. Due to the presence of various substances, a reliable, long-term sealing, good adhesion to the surface is ensured.

It is best if the places of future sealing will be pre-treated with a primer. The hardener determines the type of sealant, cure time.

According to this classification, sealants are:

- neutral;

- acidic, characterized by chemical resistance and a relatively low price.

Silicone sealants can be used to seal both cast iron pipes and plastic risers.

After polymerization, the paste becomes rubbery.

Important! It is best to use a special assembly gun when working with sealants. Thanks to him, the paste is squeezed out smoothly, easily, in the required amount.

3.4. Tow

This material, together with red lead on drying oil, for decades has been and will remain one of the most reliable among many other analog-seals.

Thread with wound tow

With the use of linen strands, in the overwhelming majority of apartments and private houses, gas, heating, and plumbing structures were installed.

Important! The use of red lead makes it possible to prevent the occurrence of corrosive processes, which cannot be said about the iron analogue.

The main advantages of sealing with tow:

- reliability;

- ease of installation. In order to make a high-quality seal, it is necessary to wind tow on the external thread, generously coat the material with red lead and tighten the fitting well. After that, you need to tighten the lock nut. Simple, reliable;

- availability, minimal financial costs;

- ensuring a high level of adhesion;

- the presence of strong fixation of the connections after tightening with a gas (pipe) wrench.

Disadvantages:

- in order to correctly install the connection and the pipe as a whole, you must have a sufficient level of professional knowledge;

- applying too much force when tightening, can cause damage to threads, fittings;

- the complexity of dismantling work, which can lead to heating of individual units, in order to replace them with others, of higher quality;

- the need to monitor the state of the system, since over time, the strands lose their original properties, which can lead to gas leakage.

Flax compaction process

In fact, this method of sealing is quite simple. It just requires accuracy and knowledge of a few nuances.

Consider the sequence of operations:

- It is necessary to separate a strand of flax with a thickness of 1 - 3 mm from the coil and smooth it with your fingers. Coarse villi are removed.

- After the strand is prepared, you can proceed to winding it on the thread, free of possible contamination. You need to rewind tightly (without gaps, filling all the grooves) and along the thread.

- It is recommended by the manufacturer to apply the paste to the cleaned thread, then wind the flax and cover it with the paste on top (the excess is removed). In practice, the first step is rarely performed, and this has little or no effect on quality.

- Having completed the previous operations correctly, you can proceed to twisting the parts. In the process of tightening, you need to ensure that the flax remains inside the connection and is minimally knocked out of the thread.

What should you pay attention to?

- The right balance. If you wind up a lot of linen, the connection may crack. And if there is not enough flax, it can be leaky.

- Tightening should be done with a certain amount of effort. If the nut is twisted easily, then there is little flax on the thread and it needs to be rewound.

In conclusion, let's highlight the main advantages of using flax:

- In comparison with other sealing materials, flax fibers have the lowest cost.

- Linen can be used at temperatures up to 160 ° C

- Despite the content of natural ingredients, fibers do not cause allergic reactions. This is important when installing water pipes.

- The service life of sanitary flax, subject to the installation rules, is 12 - 15 years.

Anaerobic sealants

Anaerobic sealants play a special role in the installation or repair of piping systems.

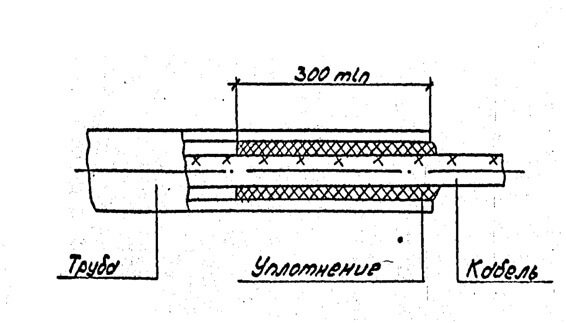

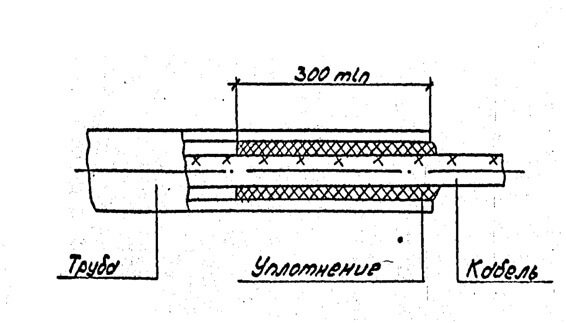

This silicone sealant is used when laying cables in the ground. Namely, if the cable line must pass through aggressive soil, then it is allowed to place the cable in an asbestos-cement pipe.

The end, at the point of exit from the pipe, must be reliably sealed to prevent moisture and soil from entering the structure.

An anaerobic sealant is used as such a sealant. An example of such a cable seal in a pipe can be seen in Fig. 1, which corresponds to sheet a5-92-45 of the Standard Project for laying cables with a voltage of 35 kV in soil.

The price for such work depends on the length and diameter of the pipe part where the sealing process needs to be carried out.

Picture 1

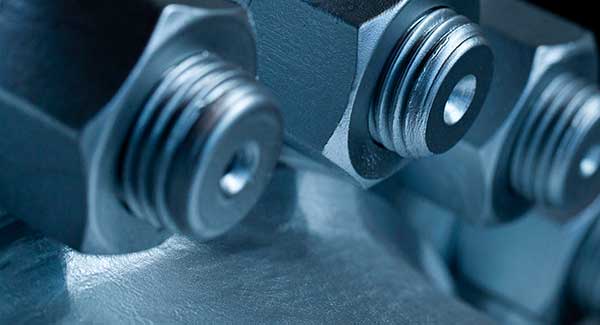

Each type of system is determined by specific regulatory documents, in which the permissible load on the pipeline is strictly regulated. Although the standards are different for different pipe connections, each regulation specifies that threaded and flanged connections must be subject to special tightness.

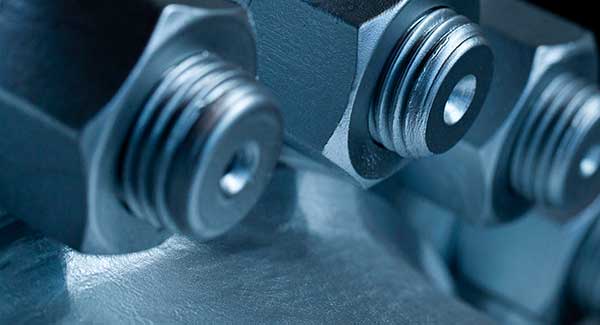

In this regard, it is necessary to use modern and reliable materials for sealing, which is an anaerobic sealant. It is used for sealing high pressure threaded connections where minimal leakage of the working medium is not allowed.

4.1. Application

Until recently, these pastes were used only in the military industry, aerospace, and the engineering industry. That is, the fact that they found their application where strong, reliable, durable connections were needed.

Today, such material is used in the repair or installation of threaded connections for water supply systems, gas and heat supply systems. They are also called thread clamps.

Anaerobic sealants are successfully used when a conventional gel pad is required. One cannot do without them, both in mass housing construction and in private households.

It can be noted that, due to its significant advantages, anaerobic sealants are becoming more and more popular when working with threaded connections.

Important! Anaerobic pastes are used in extreme pipeline operating conditions. The sealant is ideal for sealing threads with a sealant in an aggressive environment with high temperatures or pressures up to 50 atm.

4.2. Advantages and disadvantages

As with any sealant, anaerobic sealant has its positive and negative sides.

The "pluses" include:

- ease of use. You do not need to have a lot of work experience, serious skills of a plumber to learn how to use the material correctly;

- quick application and twisting, which allows you to complete the work within 20-25 seconds;

- economical consumption of substances. This means that if there is an excess of paste on one threaded connection, they are transferred to another;

- ensuring complete sealing, which allows the joints to be successfully operated in extreme temperature conditions at high pressures;

- the possibility of anticorrosive action on a metal surface;

- affordable price, given the incredible properties of the substance.

A negative point can be considered the fact that during repair or installation at low temperatures, the agent must be warmed up.

Basic sealing methods

Typically, the following materials are used to seal pipe threads:

- Linen and paint or sealing paste;

- FUM tape;

- fluoroplastic or polyamide thread;

- paste (drying or non-drying);

- anaerobic sealant.

Sealing of threads in plumbing was traditionally carried out using flax fiber with red lead, but today this method is used less and less, since artificial materials are much easier and more convenient to use.

Sealing with other materials

In addition to the aforementioned seals, they are often used for sealing:

- epoxy resin. It is clear that the principle of its action is the same as that of the glue of the same name, produced on its basis. using this substance, they connect the risers of the sewer system;

- Portland cement. With its help, more than one sealing mixture is produced, which, in combination with an asbestos rope, is used to caulk the socket joints of the pipes of the cast-iron sewage system;

- petroleum bitumen or asphalt mastic. These substances are very effective in cases where ceramic or cast iron sockets need to be sealed;

- technical gray. When using this substance, the sealing of cast iron joints and similar sockets is almost ideal.

Important! Before use, the sulfur must be broken into small pieces, heated to a liquid state and filled with cracks. The uncured substance allows the compound to be adjusted.

Sealants are different in purpose, depending on the material of manufacture. Before installing the seal, you need to remember that they are trapezoidal, shaped (P-, H-, T-shaped) and other profiles.

They are installed on pipelines, car windows, house windows. Such products are excellent waterproofers, dock seals. They can also be used as depreciation materials.

For their manufacture, special rubber is used, which is highly resistant to oils, gasoline, water, and high temperatures.

On those pipelines where oil and gasoline products are transported, one can often find the NT 42-75 / 7 seal, which is distinguished by its hardness, high heat resistance, and reliability.

The use of sealing materials in various fields

It often happens that it is necessary to securely fix the bearing surface of the pipe. To do this, use a steel pipe bracket with a rubber seal.

In the event that a leak appears in the riser not at the junction, but directly on the pipe, then rather quickly and, relatively, qualitatively, you can seal the pipe using a pipe clamp with a rubber seal.

Different seals are used in different areas of life. For example, when repairing the valve mechanism of a car, rubber gaskets are used as a seal for the tubes of the rods of the pushers.

Bracket with rubber seal

Car owners often carry out some repairs to their "iron horse" themselves. Replacing the extension arm ("crab"), laying the intake pipe, other relatively not too voluminous, but expensive work, you can do it yourself, which most amateur motorists do.

If, for example, the gasket of the "pants" is burnt out, then very quickly and reliably the assembly can be sealed with the help of high-temperature sealant, which must be applied to the gasket and securely tighten the nuts on the studs. Budget option - but reliable.

In complex technical structures, it is necessary for the seal to serve for a long time and reliably. These include powerful turbine generators, for which it is necessary to ensure a continuous oil supply to the end shaft seal.

The design of such a device, an important part of which is the anti-siphon tube of the hydrogen seal, is quite complex, like the very principle of its operation.

A special place in oil and gas equipment is occupied by a mud pipe with a mechanical seal. Among all device options, JJC products occupy a special place.

Mechanical seal

They differ:

- rational design;

- ease of installation and replacement of seals;

- long-term operation;

- reliability;

- high efficiency;

- safety while drilling oil and gas wells.

Seals are also used in the arms industry. Among fans of pneumatic weapons, air rifles of the Turkish company Hatsan are in special demand. For their successful operation, it is necessary to change the seal of the small Hatsan AT-44 air tube in time, the price of which is about $ 3. for 1 pc.

How to seal threaded connections for heating

7.1. Gaskets

Many people use end gaskets to seal heating pipes. This method is technologically the fastest, but the quality of sealing could be better.

The fact is that during the assembly of the structure, the gasket is strongly pressed by the thread and the joint density may suffer a little, since the part opposite to the external thread has a slight narrowing.

But in order for the joint to be tighter and more reliable, they use a paronite or fluoroplastic part, after the installation of which, it is necessary to securely screw the entire structure. Although it is not always possible to achieve transitions without narrowing with this method.

Considering this, the gasket is often installed when sealing sensors and instruments for measuring pressure or temperature, where the hydraulic resistance is not very high. True, experienced plumbers, for greater confidence and reliability, use an additional seal in the form of, for example, tow with red lead. They explain this by the fact that we are dealing with hot water, which is not always safe.

7.2. FUM tape

Since the coefficient of friction of the fluoroplastic tape is low, it can be used to easily assemble the whole threaded structure with its help. The advantages of the material include high chemical resistance and long-term operation.

Like all materials, FUM-tape has some "disadvantages":

FUM tape winding

- during the assembly process, it can be torn into separate pieces, or twisted back;

- cannot be used in joints with possible thermal deformations. The fact is that the tape has poor adhesion to the metal, and if the joint is "playing" - possible squeezing out of the seal;

- can act as a reliable sealant for threaded connections only up to 25 mm in diameter. Therefore, using such a material, it is impossible to completely assemble the heating system.

7.3. Tow

This simple and cheap material has been a reliable sealant for decades. Lead red lead on drying oil or ordinary oil paint is most often used for impregnation.

Despite the emergence of good modern seals, flax strands have been and remain the leader among the most reliable sealants. Due to its positive qualities, the material is often used in the installation or repair of heating systems.

Oakum is different:

- reliability;

- the quality of the seal;

- cheapness;

- ease of use.

The disadvantages include:

- limited service life;

- tendency to dry out;

- the need to have certain skills in winding and wrapping.

Modern seals installed in plumbing threaded connections

The main seals currently used by plumbers are perhaps:

- Fum tape.

- Anaerobic sealant adhesives.

- Linen (tow) with sealing paste.

- Sealing threads.

Most professional plumbers carry all four types of seals with them at all times. Because they never know in advance what they will have to face when completing the next task.

The seal should be selected based on the specific circumstances.

All seals are equally effective during installation. It is impossible to name the best or the worst among them. Typically, the choice of the appropriate one depends on the circumstances. And we will analyze these circumstances today.

A little about the connections of gas risers

Most often, gas is transported by steel pipes. Indoors, plastic gas hoses are also used. Almost always, a gas pipeline consists of several risers, and therefore the problem of their connections arises.

Gas can seep out on fittings, threaded connections. Therefore, perfect sealing of gas pipe joints is the number one task when installing or repairing a gas pipeline.

For such work, special sealants, seals, etc. are used. Let's pay attention to the most demanded of them, which by their quality have won the trust of citizens.

Rubber O-rings

This type of seal is used for joints, the distance between the ends of which does not exceed 1 mm. RUK is not used to seal couplings in which the end of a threaded pipe does not rest against the end of a nut or other pipe. They are used to seal tap connections.

Rubber o-ring

If the old HAND is damaged and the tightness of the connection is broken, turn off the water, disassemble the connection and remove the seal. If it is not possible to purchase a ready-made HAND, take the rubber (for example, from the wheel tube of a car or truck), attach the damaged seal to it and circle the contours with a handle. If the rubber is thinner than the old ARM, make two or three rings. Cut out a new seal and insert into the nut. Trim the protruding parts if necessary. A correctly marked and cut gasket is forced into the nut. Assemble the connection and check for leaks.