Wood heating stoves Termofor Fire-battery - long burning stoves

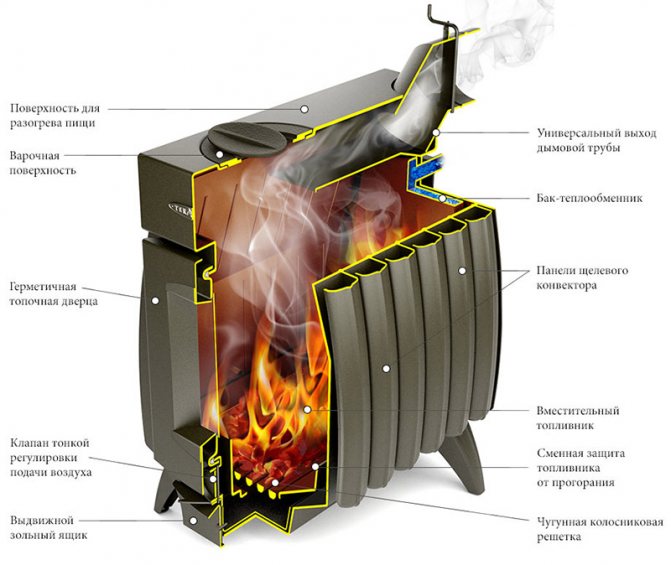

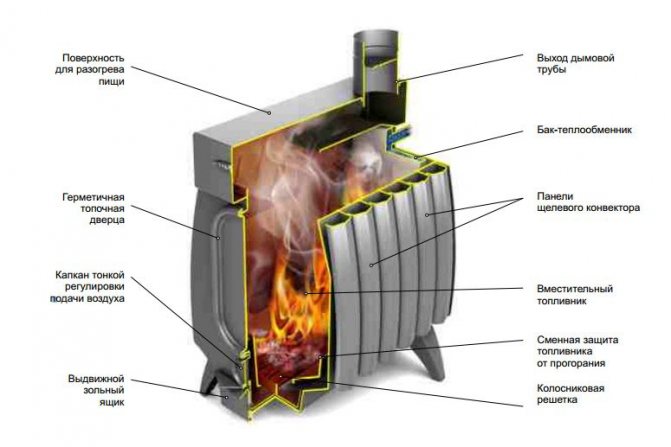

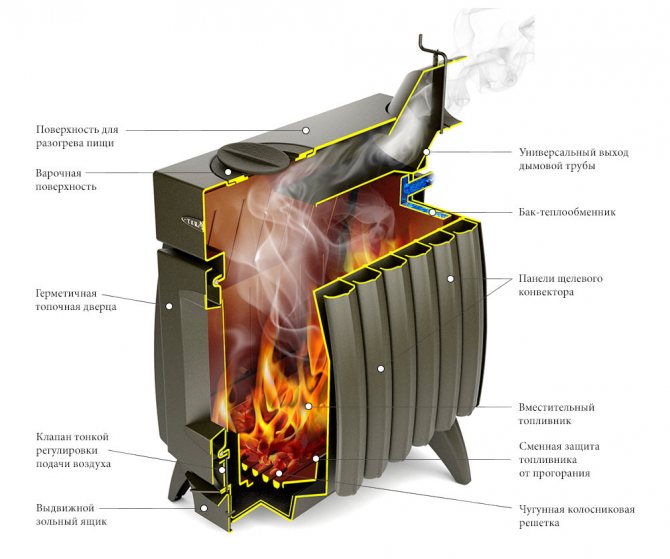

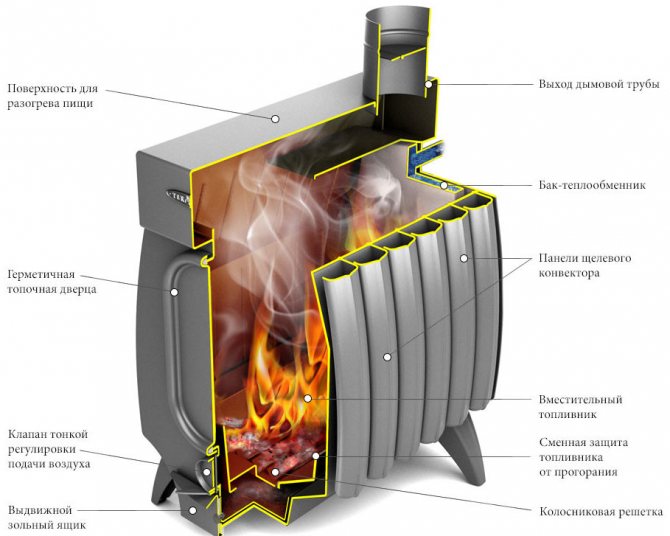

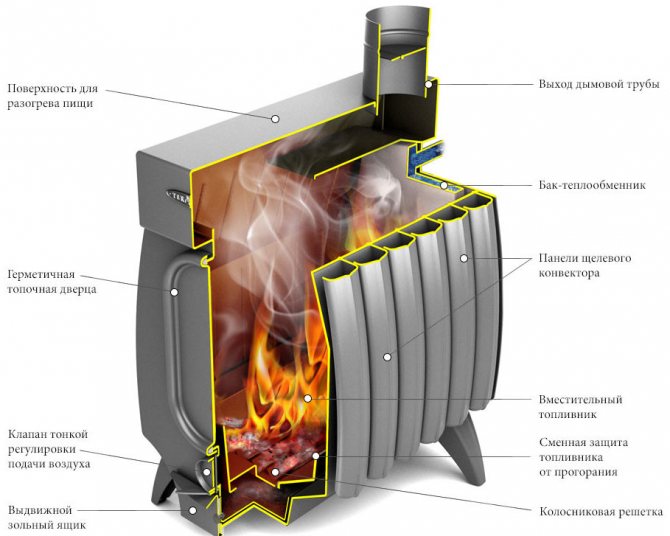

In order for the wood to burn, air is needed. To burn strongly - a lot of air, to smolder slowly - a small air leak. In the Termofor Fire-battery oven, you can adjust the air flow from the maximum during ignition to the minimum in the economical combustion mode by changing the position of the fine adjustment valve and the gate.

- Door... The rotary mechanism of the handle reliably fixes the door in the closed position, and the seal ensures reliable pressing of the door to the furnace body. The door has a size of 15-30 cm and opens at an angle of 120 °, which allows you to conveniently load the stove with wood to the very top.

- Ash box... A sealed ash box is installed in the Fire-battery ovens. When switching to an economical combustion mode, it slides into the ash pan and "snaps" behind the ledge. A seal on the front wall of the ash drawer ensures its tightness.

- Fine adjustment valve... Located under the firebox door. A fine adjustment valve is required to supply air to the furnace during long-term burning, when both the door and the ash drawer are tightly closed. Adjustment of the valve position is stepless and allows you to choose any combustion mode - from intensive to complete damping of the furnace.

- Shiber... A damper is a damper in the chimney outlet for regulating the draft in the chimney. Its free rotation is excluded by the fixed positions of the handle. Even in a completely closed position, the chimney is not completely blocked by the gate, it remains possible to create a minimum draft.

Installation features

When installing the stove Fire Battery, it is necessary to take into account the nature of the combustion. Despite the presence of convection channels, which are a screen, the oven gets very hot. This could cause a fire risk.

The oven is an air spray. The process is based on natural air convection and this must be taken into account when installing the equipment. The operating instructions describe in detail the installation process of heating stoves Fire Battery of various modifications.

The best option for placing the stove is in the middle of the room. Convective currents should not have obstacles in their path. However, it is not always convenient to install equipment in this way. Therefore, usually the installation of the stove is carried out near the middle of the wall. All furniture in the vicinity is removed so as not to obstruct the diffusion of air.

The equipment will only heat the room in which it is installed. If it is a Fire Battery 7B, 9B or 11B, then it is allowed to connect up to 2 radiators. Then there is an opportunity to heat a nearby room.

Oven Fire-battery = Oven Fire-battery

Heating stove Fire-battery is also a stove for cooking. Even if the electricity is turned off, the Termofor Fire-battery oven will warm you, feed and give you something to drink. On the upper surface of the firebox there is a cast-iron burner with two rings of different diameters for dishes of different sizes. Even through this window, you can add firewood to the firebox and clean the top of the stove from soot.

Note! There are no cast iron burners in the Fire-Battery Light models. The upper surface of the Fire-Battery Light ovens can be used only for heating food (read about the Fire-Battery Light ovens below).

Purpose and basic requirements

Fire-Battery is an air-heating stove. That is, it heats the air in the room. And it does it quickly and efficiently, it burns for a long time. Manufacturers declare that a full load of dry firewood, depending on the model and the specified settings, burns for 8-16 hours.In reality - according to users' reports - on dry wood, but with an incomplete bookmark - 6-9 hours. There were no large numbers in the reviews.

“I arrived at the dacha, there was no frost yet - around 0 ° C, but the house was cold. I threw less than a quarter of the firebox, burned for 20-30 minutes in the stove-stove mode (I definitely did not detect it, but it felt like it was somewhere like that). During this time, the temperature rose by 10-15 degrees. The heating rate is very pleasing. Then he closed the valves, the combustion died down, sometimes tongues of bluish flame appeared. Everything burned out, into dust, and there was very little of it. "

“I have a Fire-battery 7. I have stoked it 5-6 times already. At night, I throw in ¾ volume of firewood, and they burn until morning. During all this time, I cleaned it only once, and that ash was from a gulkin's nose. The wife was even upset, she decided to fertilize the garden with ash. "

An important requirement for operation: use only firewood. This is an exclusively wood-burning stove. They must be dry to reduce condensation and soot. For greater convenience, later, after firing up, you can pour pellets from above, through the burner.

The main mode is smoldering. When firing up the stove and warming up the chimney, intensive combustion with an active air supply is necessary (all valves are open). After the draft has stabilized, the dampers / gate valves are closed and the furnace goes into smoldering mode. This mode accounts for up to 70-85% of the burnout time of the bookmark. Specific figures depend on the heat capacity of the wood, the degree of their dryness and the "starting" temperature.

If you need a heating stove for a temporary residence, Fire-Battery is a good choice. She will quickly cope with the task. All users noted that they took off their jackets much earlier with this oven than with all the previous ones. And in the "previous" were brick and other metal, including Professor Butakov of the same Termofor.

For heating houses of permanent residence, metal stoves are not recommended at all, and this one too. Although it is effective and “softer” it heats, it is still better for a house with permanent residence to have a hot water boiler. Moreover, this opinion is expressed by the developers themselves. But, as they say, the owner is a master.

In the active phase of combustion, the flame is yellowish-red

Probably, to emphasize the "country" purpose of the stove, it has a burner. For a summer cottage or garage, this is great: while the firewood bookmark is flaring up, you can boil the kettle, cook / heat food. Then, when it goes to the smoldering mode, it becomes almost useless, except to maintain the temperature in the kettle.

This burner is not included in the second line - the economy version Fire-battery - LITE. Probably because it was the presence of the burner in the upper part of the stove that caused the most questions. In theory, smoke and carbon monoxide can seep into the room between the rings. Indeed it can, but only if there is no traction. That is, during kindling (but at this moment all stoves are smoking) or if the chimney is made incorrectly or clogged. In all other cases, the Fire-Battery does not smoke.

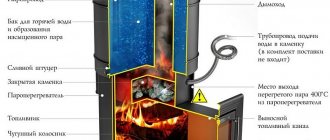

Fire-battery with water circuit

The presence of the letter "B" in the name of the Fire-battery furnace modification (for example, the Fire-battery furnace 9B) means the presence of a heat exchanger tank inside the firebox of the furnace. It is designed to heat domestic water. The heat exchanger itself has a small volume - 1.3 liters, but is capable of heating water in an attached remote tank with a volume of up to 100 liters. For this, the remote tank and the heat exchanger must be connected with pipes; nozzles for connecting the water heating system protrude on the rear wall of the furnace (external thread G3 / 4). The principle of operation of the tank-heat exchanger is based on the physical properties of hot water to rise, and cold water - to fall. Thus, having created an opportunity for the water cycle in the heating system, the water in the remote tank is gradually heated, and you have the opportunity to wash or wash with hot water.

The article "All About Heat Exchangers" tells in detail about the nuances, dimensions and precautions when installing a water heating system using a heat exchanger built into the furnace.

Ease of installation and operation of heating furnaces Termofor Fire-battery

Cooking and heating water with a heating stove is, of course, good, you say. - But first it must be installed, then heated every day, and also periodically cleaned. We did everything to make it easy and convenient!

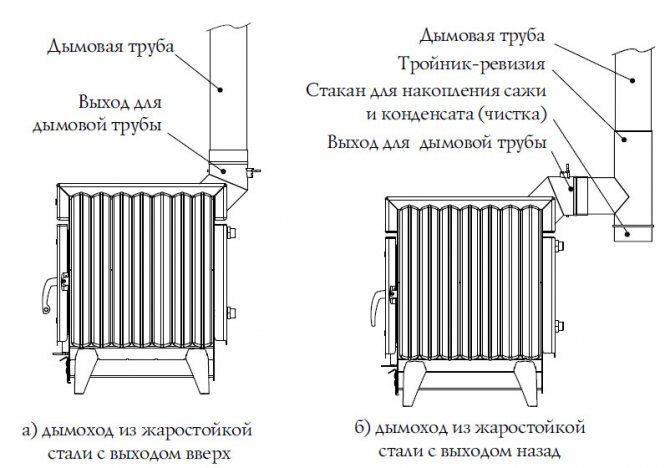

- The universal chimney outlet allows the chimney to be led out both up and back. Note! The Fire-Battery Light stoves (see below) have only one version of the chimney outlet - upward.

- The large, vertically oriented firebox door allows you to conveniently fill the stove with wood to the very top.

- A spacious firebox allows you to fill the stove with the maximum amount of wood for long-term continuous burning.

- The door has a translucent screen made of SCHOTT ROBAX heat-resistant glass. It doesn't just give the oven a sophisticated look. It is convenient to control the combustion process through this window. Self-cleaning glass.

- The well-thought-out geometry of the firebox eliminates the accumulation of unburned fuel, which is gradually poured onto the grate under the action of gravity.

- Replaceable protection protects the firebox from burning out in the place of accumulation of hot coals. If necessary, the protection can be easily changed to a new one at home.

- To remove ash from the ash drawer, you do not need to turn the drawer over, you just need to tilt it like a scoop with garbage. Easy and convenient!

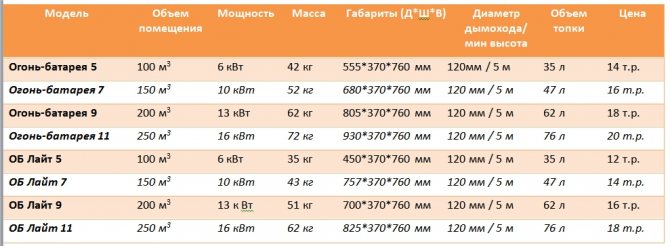

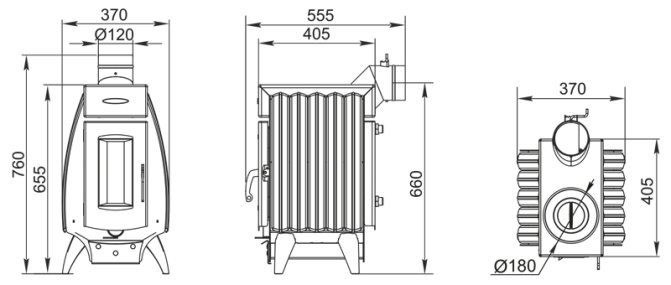

Heating stove Termofor Fire-battery Characteristics and dimensions

A table is the best way to organize your data. Ask Mendeleev, he will confirm. Therefore, we have collected for you in one table all the characteristics of the Fire-battery ovens, see:

| Fire-battery model | 5 B | 7B | 9B | 11B | ||||

| Type of fuel | Firewood, peat briquettes, pellets, wood chip briquettes for closed type heaters | |||||||

| The volume of the heated room, max | 100 cc m | 150 cc m | 200 cc m | 250 cc m | ||||

| Rated power | 6 kW | 10 kW | 13 kWt | 16 kWt | ||||

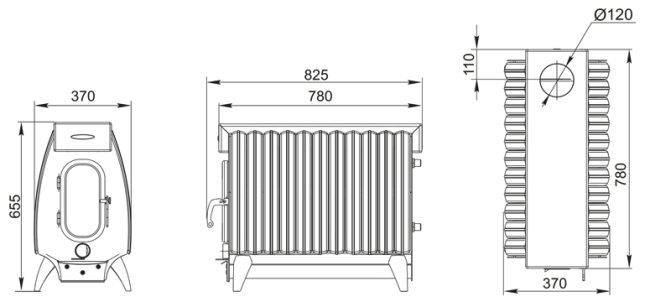

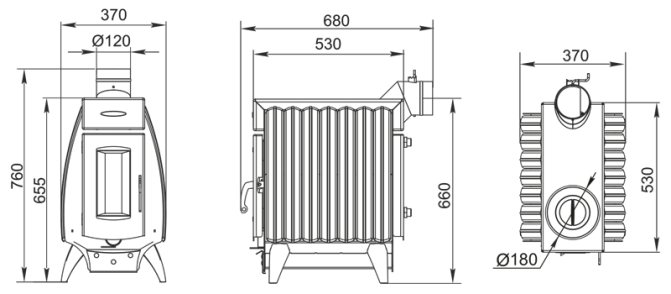

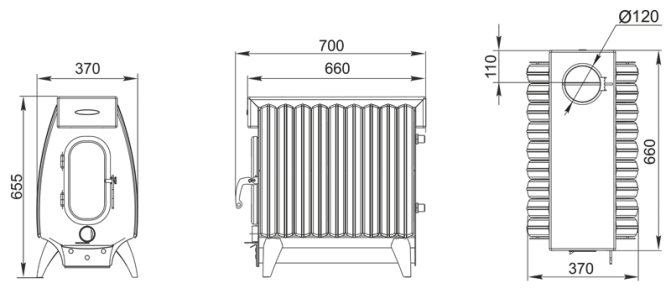

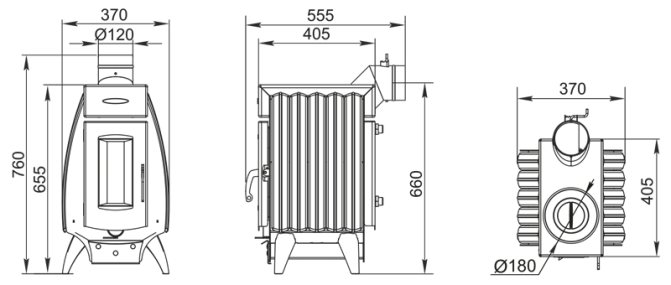

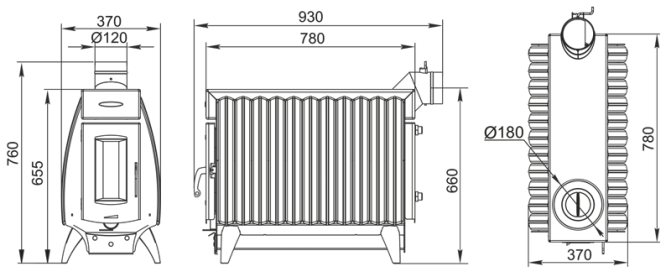

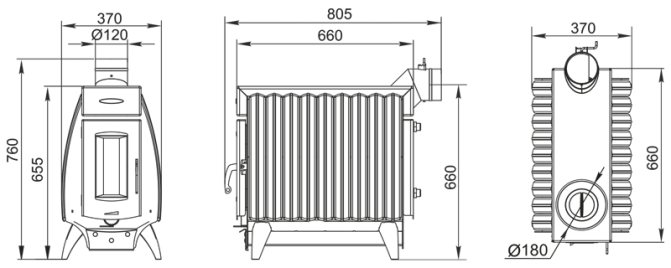

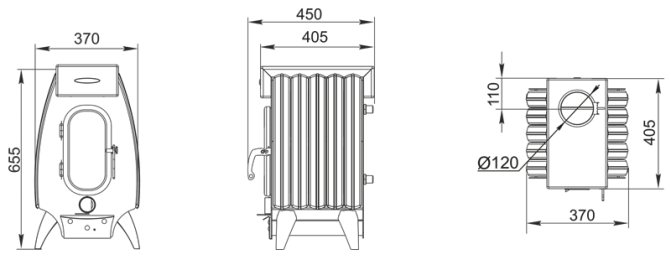

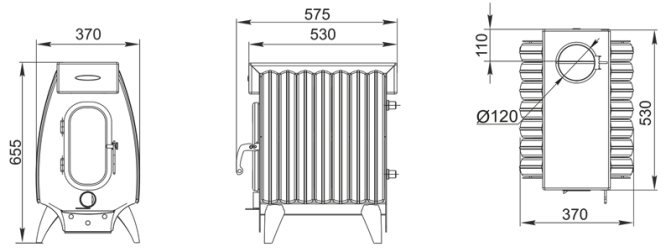

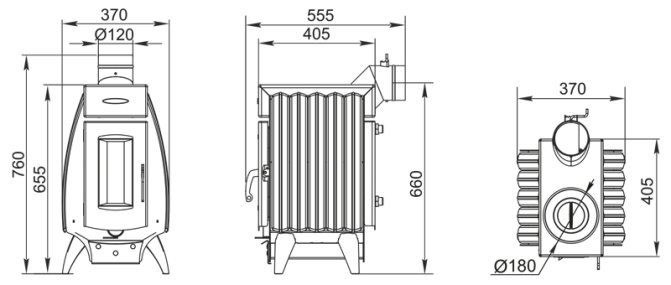

| Width | 37 cm | |||||||

| Depth | 55.5 cm | 68 cm | 80.5 cm | 93 cm | ||||

| Height | 76 cm | |||||||

| Weight | 42 kg | 44 kg | 52 kg | 54 Kg | 60 Kg | 63 kg | 72 kg | 75 kg |

| Fireplace door opening | 15 * 30cm | |||||||

| Log length, max | 29.5 cm | 27.5 cm | 42 cm | 40 cm | 54.5 cm | 52.5 cm | 67 cm | 65 cm |

| Combustion chamber volume | 35 l | 32 l | 47 l | 45 l | 62 l | 59 l | 76 l | 73 l |

| Fuel loading volume, max | 30 l | 27 l | 42 l | 40 l | 57 l | 54 l | 71 l | 68 l |

| Chimney diameter | 120 mm | |||||||

| Recommended chimney height | 5 m | |||||||

| Heat exchanger tank volume | — | 1.3 l | — | 1,3 l | — | 1,3 l | — | 1,3 l |

Furnace Termofor Fire-battery LITE

"Any whim for your money" - this is how they say in our time. But if you are not a capricious blonde, you can save on those heating stove amenities that you do not need. The structure and design have been simplified as much as possible while leaving a beautiful heating stove equipped with a large sealed firebox and a high door; the oven, which is distinguished by excellent heating technology and fine regulation of combustion, provides the ability to heat water and reheat food. The cast-iron burners and the rotary chimney outlet, glazing and the convector on the door were removed. The replaceable protection of the firebox from burning out was still left - let the Fire-battery stove last longer.

Thus, all the technical characteristics on the Fire-battery Light model can be viewed in the table above. And here is another small table for comparing prices:

Instructions on the oven Termofor Fire-battery (.pdf)

Operation manual for heating furnaces TMF Fire-battery LITE (.pdf)

Water circuit connection. Pros, cons, unexpected opportunities.

Good day!

As I wrote above, the factory scenario for using the built-in heat exchanger is not for real life. It is difficult, dangerous, expensive, imposes a lot of restrictions, and when used periodically in winter, it is basically unusable due to the danger of defrosting the system. He also pointed out other disadvantages. In addition, the presence of a heat exchanger forces the oven itself to be cleaned at least twice a week. Due to the fact that its wall warms up only slightly above the temperature of the water in it, combustion products intensively condense on it and quickly tar it up.The gaps between the side walls and the heat exchanger body are overgrown with resin, and it has to be removed from there. Although, this is uncritical, you can not pay attention, the heat transfer will simply worsen.

So is this very heat exchanger needed? I will answer: I bought the first OB5B out of curiosity, the second OB7B quite consciously!

Now a small lyrical digression. There are jokes about our habit of starting to read instructions only when something has already gone wrong. But with a long burning stove, jokes aside. It is absolutely necessary to read and strictly follow the factory instructions. It contains all the necessary drawings, dimensions, as well as warnings about the dangers of certain incorrect our actions. I will refer to it. However, those who write the instructions have another goal: to describe all possible restrictions in order to minimize the likelihood of warranty claims. I sometimes ignore the requirements of the instructions, for example, the following: installation should be performed only by certified personnel from a specialized organization, etc., etc. In my house all the systems were installed by one person - myself. Therefore, if somewhere below I describe something that contradicts the instructions, take it not as a recommendation, but as actions that may not be worth following after me. That is, I do not advise you to do as I did, but simply report what I did at home and how it works.

Let's get back to the topic. The instruction expressly prohibits “connecting the heating system to the heat exchanger”, “operating the water heating system under pressure other than atmospheric pressure”, as well as pressurizing the heat exchanger and the tank with increased pressure.

We will fulfill this strictly!

The paragraph from the instruction about the fact that "in case of boiling water in the tank, you should add cold water to it", and "do not fill to the top", make sure that it does not overflow, looks to me just like a joke. Here's to you, and the utilization of excess heat!

There is a recommendation to use only clean (as I understand it, in terms of corrosiveness and hardness) water.

For me, this means that an open system is possible with an expansion tank breathing into the atmosphere, filled with a non-freezing non-aggressive liquid, with the utilization of excess heat in some kind of heat exchanger, for example, a boiler or radiator. The main thing is that there is no excess pressure anywhere, no stop valves, by closing which, such a pressure could be foolishly created. Well, so that steams

ethylene glycol away from people. That's all, further - a matter of technology. Tomorrow I will post specifics and photos.

- Purpose of furnaces of the Fire Battery series

- Types of stoves of the brand Fire Battery Fire Battery 5

- Fire Battery 7

- Fire Battery 9

- Fire Battery 11

- Furnace cost

- Where is the best place to place the oven

The Termofor company is known for its high-tech products of heating systems with good thermal efficiency. Particularly noteworthy are the series of air heating equipment.

Stove Fire Battery, presented in four basic modifications and several more derivatives in the Light series. Additionally, boilers are offered with the "B" index, indicating the presence of a heat exchanger.

Ford Bronco Bronchit F350 ›Logbook› Heating in the garage. Fire Battery 7 light. Thermophore.

There were diesel TPs and gas and electric ones ... but I never used a wood-burning one in garages. Weighed and pondered for a long time. I read storytellers at the forumhaus. In the end, it is what it is. Thermoforovskaya Fire Battery 7 light.

Ideally, under ideal conditions, etc. etc. for 150 cubic meters. I probably have 120. It is clear that if it is enough to turn well in an insulated insulated room, then the heat will remain for a very long time. Therefore, I have already taken not 5 but 7 sections. Yes, and more logs will climb.5th is very small in length.

If you look closely, you can see a defect, which I did not notice in the FIRM Magazine on Signalny. There is no bend on the third gill of the battery. And not that they forgot to bend it, but stupidly chopped off the wrong one. It seems that more jambs are not found both when viewed from the outside and from the inside. If it does not disperse at the seams during combustion, then okay.

So the rest is kind of neatly done, but not to say that it is fantastic, as advertised on the site. It would cost 10 - 12 and not 14 rubles, then everything would be completely justified.

We put it in half a day. On sealant, clamps. We must pay tribute, the branded chimney fits well and the knees fit tightly into each other.

Then I cut the roof for half a day and smeared it so that it was for sure))

The pictures show the accompanying tools and materials.

Red is a non-refractory sealant, which is 300 degrees and 600 degrees for a short time. Under it, with a clamp to the pipe, he pulled a rose from the corrugated board, which he cut with a grinder.

Flash both for rivets and for roofing screws. And then and then smeared with a sealant before planting. Then another on top. And then on the top I still poured tar with bitumen roofing. No pictures really. it was already dark.

Well, then another sandwich, its finish and fungus.

So I didn't take a picture during the day. Then I will add.

Before installing, I also put a reflector behind the stove.

I stood for a couple of days, after which I heated it with the gates open.

She smelled, burning with oil and polymerizing the paint as stated in the instructions. The draft is good, although instead of the recommended 5 meters of the chimney, it turned out to be only 4.

When it gets colder, let's see how it can heat. So fry is not bad yet. In any case, how will I come to an unheated garage, turn on the diesel engine, change clothes, light up the stove, then turn off the accident and this one should keep warm. But that's in theory. Wait and see.

Colds set in. The oven began to be used more often. The gate entrance to the stove was constantly walking, the sealant came off, cracked, and so on. When you look into the stove, you can see gaps already. Perhaps even siphoned through it.

It is clear that doing this is not the best option. But the runs at the stove will only be on the outputs, basically. Therefore, when replacing the gate, when it burns out, I will stupidly cut it off, remove the remnants with a stripper and weld the gate on the removed stove before installation. When the stove in the corner is not easy to burn. I hope this will happen in 3-5 years ...

The last photo when firing up. When it comes to normal mode, there is little smoke. When the coals appear, there is almost no smoke.

Purpose of furnaces of the Fire Battery series

Solid fuel convection boiler of long burning Termofor Fire Battery, in the basic modification, is designed for air heating of the room.

The numerical value after the name indicates the number of side convector ribs, resembling a radiator in appearance. Additionally, there is a cooking space for heating and cooking food. Basic version models are made with glass with a self-cleaning surface.

Furnaces with the "B" index, with a water circuit, have a built-in heat exchanger. The capacity is not enough for full heating of the house, but for additional heating of a separate room with an area of 5-8 m², there will be enough heat transfer from the circuit.

The possibility of using it for hot water heating is limited. Really satisfy the needs for hot water supply for 1-2 people. For this, a special external hot water tank is installed. During the operation of the stove, the liquid heats up quickly. The principle of indirect heating is used, so the water inside the tank does not boil.

Air-heating stoves with a water tank of the "B" series can theoretically be used for a bath, although this product line of the company is not specifically intended for this purpose. To heat the dressing room or the washing room, you can connect water heating radiators.The power of the oven will be enough to connect 1-2 batteries.

Light series, promoted as an anti-crisis option. The price difference between heat generators is approximately 2 thousand rubles. The cost reduction became possible due to the fact that in the Light series the hob and glass insert in the door of the combustion chamber are removed. Otherwise, the characteristics of the Light oven remained the same.

Regardless of the model chosen, the principle of long burning is used. Firewood is burned in gas generation mode.

Types of stoves brand Fire Battery

If you count, the Termofor plant produces about 12 different modifications in the Fire Battery series. To facilitate the choice, all ovens are divided among themselves according to several criteria:

- The basic modification is hot water boilers equipped with a glass insert for the fire door and a hob.

- Light series - stoves without additional functionality.

- Index "B" - a model with a built-in heat exchanger.

In each series, there are three modifications, which makes it possible to choose the best suitable stove.

Fire Battery 5

Heating stove Fire Battery 5, designed for small spaces. The maximum heated area is not more than 60 m². In the design, traditionally for this series, a slotted convector is provided.

The volume of the firebox is only 35 liters. The maximum length of logs is no more than 30-35 cm. In the long burning mode, the stove will work for about 6 hours.

Fire Battery 7

Wood burning stove Fire Battery 7, equipped with seven convection fins on each side of the body. It features an enlarged combustion chamber, compared to the previous version, with a capacity of 47 liters. The maximum length of logs is 35 cm.

Fuel is loaded through the firebox door or after removing the cast-iron cooking rings located on the upper horizontal surface of the furnace. The ash box is sealed, you can clean it while the furnace is burning without fear of smoke entering the room.

Fire Battery 9

Oven Fire Battery 9, has several features:

- Nine slotted convection fins, on each side.

- Possibility of choice of color - ovens are offered, painted in a traditional shade - anthracite, modern - chocolate or metallic.

- Productivity is 13 kW.

- The loading chamber holds 62 liters, which is enough for full heating of a residential building of 120-130 m² for 6-8 hours.

In the Fire Battery B series, in the basic configuration, a remote stainless steel water tank is provided. The heat exchanger capacity is sufficient to provide hot water supply or to connect 1-2 heating radiators.

Fire Battery 11

Metal stove Fire Battery 11, the most powerful in the series, can heat a living space of 150-160 m². The design is distinguished by an elongated combustion chamber that looks like a vault.

The door is designed to freely fill the entire firebox with wood from top to bottom. It is possible to add fuel during combustion through the hob, if it is provided in the selected model. The weight of the stove excluding the mass of firewood, 72 kg.

Furnace cost

The price of the Fire Battery oven depends on the selected index and the presence or absence of additional functionality:

- OB 5 is the basic model, it will cost 14 thousand rubles, a series with a heat exchanger will cost 16 thousand rubles. The Lite version will cost 12 thousand rubles.

- OB 7 - a lightweight oven in the Light series, it will cost 14 thousand rubles, the standard version is 16 thousand rubles. The presence of a built-in heat exchanger increases the price up to 18 thousand rubles.

- OB 9 - a standard stove, offered for 18 thousand rubles. Enveloped version, for 16 thousand rubles. A series with a heat exchanger will cost 20 thousand rubles.

- OB 11 - a stove without a hob and a glass insert on the door costs 18 thousand rubles. For a standard model, you will have to pay 20 thousand rubles. The presence of a heat exchanger increases the price up to 22 thousand rubles.

To calculate the cost of installing the oven, add 10-30% of the costs required for the installation to the price declared by the manufacturer.

Advantages and disadvantages

The advantages of the oven are as follows:

- The absence of welded seams makes it possible to use the stove in different places without fear of ruining the appearance of the room with it.

- Thanks to slotted convection pipes, heat is evenly dissipated in all directions. There is no heat, even near the stove. A shielding effect is observed when heat is propagated in the form of infrared radiation.

- Increased efficiency, which leaves 87%.

- Large fuel chamber space. Its special design allows the ash to fall into the container below. Unlike other stoves, there is no need to remove the combustion products here.

- The presence of 2 dampers allows you to regulate the combustion process. One controls the flow of oxygen, and the second removes the smoke.

- The possibility of replacing the combustion chamber. As a rule, their service life is now at least doubled.

- In heating furnaces Fire Battery, grates are made of cast iron. Thanks to this, all fuel is completely burned out.

Furnaces of this type also have disadvantages:

- Soot that appears on the glass during firing up. The reason is the high moisture content of the wood. Further, it self-cleans, under the influence of a flame.

- If the chimney above the firebox does not have a height of 5 m, then during melting, a small amount of smoke will enter the room. He comes out from under the burners.

- With poor thermal insulation of the chimney, its internal passage decreases. This is due to condensation, which, together with ash, accumulates inside the pipe.

- If a heat exchanger is installed in the furnace, then there must be water there during heating.

How to heat the stove

When deciding which type of fuel to use for the furnace, the Fire Battery series, you should contact the manufacturer himself for explanations. Detailed instructions are provided in the instruction manual. In particular, it states:

- The main type of fuel is wood. The use of coal is strictly prohibited. It is better to use solid wood (oak, beech, acacia) with a relative humidity of no more than 20-25%.

- The length of the firewood - the combustion chamber is designed for loading logs no more than 30-35 cm. When stacking, take into account that it is necessary to leave a sufficient gap to close the door.

- Additional type of fuel - it is allowed to heat with wood derivatives. You can use pellets, briquettes, sawdust, wood chips, provided that their moisture content is within the limits specified in the instructions.

Correctly selected fuel makes it easier to ignite the stove and reduces the amount of smoke produced.

Technical specifications

Depending on the modification, the heaters differ in power, dimensions, weight, and the number of convector pairs. A general characteristic for the entire Fire-Battery series is a 15x30 cm firebox and a chimney cross-section of 120 mm. The main parameters of the devices can be studied in the table.

| Name | Room volume, m3 | power, kWt | Weight, kg | Dimensions (LxWxH), cm |

| OB-5 | 100 | 6 | 42 | 55.5x37x76 |

| OB-7 | 150 | 10 | 52 | 68x37x76 |

| OB-9 | 200 | 13 | 62 | 80.5x37x76 |

| OB-11 | 250 | 16 | 72 | 33x37x76 |

The series marked B is distinguished by a stainless steel heat exchanger, suitable for heating and hot water needs, provided that it is supplemented with an expansion tank.

How to install the boiler correctly Fire Battery

Stoves for home on wood burning long burning Fire Battery, have convection channels running along the sides of the stove, serving as a kind of screen that protects against the hard radiation of steel. Despite this, the housing gets very hot, which, under certain conditions, can cause a fire.

When installing the stove, in addition, the peculiarities of its work are taken into account. The stove works like an air heater using natural air convection. When installing and choosing a location, take this feature into account. The best placement guide, gives detailed instructions for use.

Where is the best place to place the oven

Metal heating stoves on solid fuels of long burning Fire Battery, refer to heating equipment of the convection type. For normal operation and uniform heating of the room, it is necessary that there are no obstacles in the path of convective flows. Optimal placement of the stove boiler, in the center of the heated room, which is not always possible.

For this reason, it is best to place the stove against the wall, approximately in the middle of the room. Do not place furniture and other objects nearby that could interfere with the normal circulation of heated air.

Don't worry about the stove ruining the design of your home. The air-heating interior wood-burning heating and cooking stove Termofor Fire Battery, is distinguished by a beautiful appearance and modern design.

Unlike other models by Termofor, air ducts cannot be connected to the heater. The stove will only heat up the room in which it is installed. If necessary, you can connect 1-2 heating radiators (the function is provided for models of the B series) and warm up a small adjacent room.

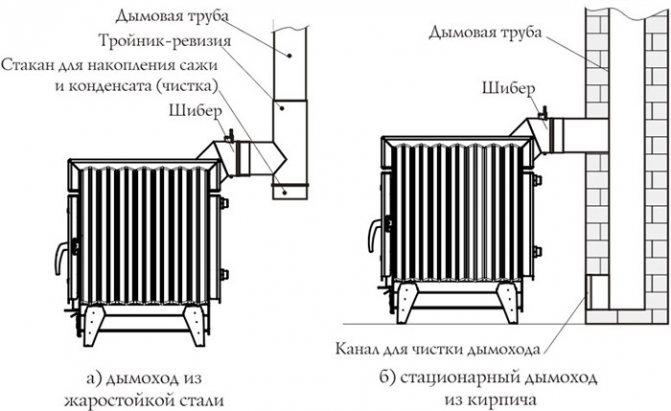

Which chimney to choose

At the stage of connecting to the chimney, up to 80% of all errors are allowed that affect the further operation of the Fire Battery stove. The choice and method of installing a chimney should be taken seriously.

The work is performed following the following guidelines:

- The choice of material - for long burning mode, the traction characteristics are critical. Lack of intensity of smoke removal leads to the accumulation of resin and accelerated overgrowth of the pipe. For connection, an insulated stainless steel chimney, such as a sandwich, is suitable, as well as a ceramic analogue.

- Insulation and safety rules - the temperature of the smoke in the chimney at the exit from the furnace reaches 450-550 ° C. The gate heats up to a bright crimson color. When passing through floor slabs and roofs, it is imperative to make a fire cut filled with non-combustible insulation.

Both internal and external chimneys should be assembled from insulated sandwich pipes. The advantage is fast assembly and stable traction.

The minimum height of the chimney is at least 5 m. The chimney is raised, regardless of the level of the roof relative to the ground.

Fire safety during installation

During the heating, the body of the stove and chimneys become very hot, which can cause a fire. Fire safety rules relating to all solid fuel units prescribe the mandatory implementation of the following recommendations:

- Installing the stove on wooden floors - a protective layer of brickwork (flat brick) is made. The pillow is obtained with a height of up to 10 cm. Brick thermal insulation during the installation of the stove ensures maximum safety. In rooms with concrete floors as a base, ceramic tiles are allowed. If the stove is not insulated from the wooden floor, the likelihood of a fire increases several times.

- Installation of a ceiling cut - either a ready-made module, sold in specialized stores, complete with a chimney, or a self-made structure is installed. The latter is made in the form of a box 50 * 50 cm filled with mineral or basalt insulation.

The walls around the furnace are protected by a steel sheet with a heat-insulating layer underneath. Possible facing with ceramic tiles. The distance from the walls when installed in a wooden house is at least 120 cm. After the walls are insulated and protected from fire with a steel sheet, the gap is reduced to 50-60 cm.

Fire Battery - owner reviews of ovens

You can find a variety of reviews about Fire Battery ovens. Some owners are unhappy with the purchase and point to several reasons:

- Self-cleaning glass cannot be cleaned.

- When the door is opened, smoke enters the room.

- Rapid overgrowth of the internal lumen of the chimney.

At the same time, comparing Breneran, Buleryan or Fire Battery among themselves, buyers often pay attention to the fact that the first models do not have such problems. What are the complaints about and is it really that bad?

What is good about a wood stove

Heating stove Termofor Fire Battery, in fact, is characterized by thermal efficiency, reliability and performance. The following advantages are noted:

- Large dimensions of the door - the dimensions are sufficient for laying firewood for the entire volume of the fuel chamber.

- Burning time - the stove works in an autonomous mode for 6-8 hours. At the same time, the room with the area specified in the documentation is fully heated.

- The presence of additional functionality - Fire battery, these are heating stoves with a cooking function. On top of the body there is a single hob made of cast iron, which is well and quickly heated to the required temperature in the mode of normal and long burning.

- Cast iron grate in the furnace - ensures that there is no undercooling. Distributes air flows evenly in the combustion chamber. Does not deform or burn out over time.

- The service life of the furnace is the estimated operating time, 5-8 years. For the first year of service, a factory warranty applies.

The high efficiency of the furnace is ensured through the use of the gas generation mode. Feature - high heat transfer and rapid warming up of the heated room.

What is the difference

A few years earlier, at the same Termofor, a good line of heating furnaces was developed by Professor Butakov and a more budgetary one - Student. These units have shown themselves well, are in stable demand and have good reviews. However, manufacturers claim that the Fire-Battery is much better. Below we will consider a list of its advantages and differences.

More stylish design

This point can be left almost without comment, since the difference is obvious even in the photo. There is only one thing to say: the design is designed so that there are practically no welded seams on the body, which, even with high quality, still remain seams and spoil the appearance of the same "Student".

The view is really non-standard and original

“I had a Student. Because of the hotplate at the top, I almost bought it again, but decided to take a chance and buy the same Fire-battery. The indisputable plus of the Battery is that 15 minutes passed from the beginning of the firebox to the moment the jacket was removed. And in general, from her - continuous positive emotions: I really like her outwardly, and I am a designer, so it's not easy for me to please. "

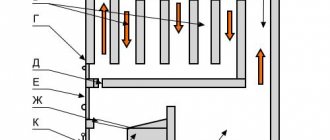

Heat flow structure

The "ribs" protruding on the sides are not made for beauty, they are slotted convectors. With their help, hard heat radiation is converted into a softer, convectional one. To put it simply: even during the period of active combustion, only pleasantly warm air comes from the Fire-Battery, and not heat. It is worth dwelling on this point in more detail.

Metal ovens are shielded and unshielded. Most of the metal unshielded stoves (such as stoves) heat the air in the room from the incandescent body. The air located nearby heats up, rises, and colder air comes in its place. The whole room is gradually warming up, but a pronounced unevenness remains: it is very hot near the stove, in the corners, it can even be cold. At the same time, in the active phase of combustion, the heating of the metal walls is such that a noticeable wave of heat rushes from the body. It is uncomfortable with such a stove even in the same room, but next to it, it is almost impossible at all. In furnaces of this type, about 20-25% is transmitted by infrared radiation, 77% - by hard heat.

Comparative table of some characteristics of two popular ovens

To make the sensations more comfortable, the walls of the body are shielded: at some distance from the firebox, one more (sometimes two or three) layers of metal are installed.Moreover, at the bottom and at the top, gaps are left, that is, the body is closed leaky. This is done so that air rises along the body. Passing along the hot walls, it heats up, cooling the metal and carrying heat into the room. Such ovens are also called convective (convection is the movement of air due to temperature differences). With this structure, heating is faster and more even, the sensations are more comfortable, the fuel consumption is less. Here the ratio of soft and hard heat depends on the number of screens and the design of the furnace, but is approximately in the 40/60 region.

The next step is the so-called "tube" furnaces. Like Buleryan, Breneran, Professor Butakov and Student. In them, instead of a screen, hollow pipes are welded into the body. The principle is the same: cold air enters the lower part of the pipe, passing through the pipe, it heats up and comes out at the top. Since the inside of the pipes goes into the firebox, heating is faster. Due to better shielding and more efficient heat transfer, the ratio of hard and soft heat is about 50/50 (the branded Buleryans are better).

Heating stove Fire-Battery in section

The Fire-Battery designers claim that due to slotted convectors, the ratio of soft to hard radiation is 77/23. Slotted convectors are pipes with a longitudinal cut. They are welded onto the body. The internal location was abandoned, since most of the Student's burnouts were located exactly at the junction of the body and pipes. This means that there is no intense heat near the stove. This is what many owners say.

Actually, the fact that you can sit next to the stove, when it is in active combustion mode, can be observed in the video.

Firebox volume

The dimensions of the firebox are decent, but what is more important - the door is high and you can load firewood almost to the very top. That is, with the same external dimensions with the same Studenot, you can put more firewood in the Fire-Battery. It is clear that more firewood burns longer. This was noted in the same reviews and more than once: a full load burns for at least 8 hours. That is, having loaded the stove in the evening, in the morning you get up in a still warm house and you do not need to get up at night. Moreover, residents of the northern regions speak about this, according to the results of using during frosts -25 ° C or -30 ° C in wooden houses from a bar (summer cottages).

Easy control of combustion intensity

There are quite a few other stoves that use the principle of long burning. The biggest problem they have is the regulation of the oxygen supply, since it is its amount that affects the intensity of combustion. Most of those who have used the Battery-Fire Stove note that it is easy to control the intensity of combustion.

This is achieved by the tightness of the ash pan and the door, which almost excludes air leaks. Its amount is regulated by a small gate located below the door and a sealed ash pan. To completely reduce combustion, you can additionally break the gate on the chimney. This will reduce cravings and the combustion will be less intense.

Gate valve on the pipe

Just do not be afraid that by blocking the chimney, you will get burned. All modern furnaces are equipped with gates, which simply cannot completely block the pipe lumen: some part of the plug is cut out in them. So even in the "closed" position, there is a gap of about 20-25% of the diameter. This is sufficient for traction to remove gases.

Secondary air supply pipes

It must be said that even in the mode of smoldering, tongues of fire still flare up in the furnace. This is due to the afterburning process of gases. When wood smolders in conditions of lack of oxygen, a large amount of combustible gases is formed. Having risen up, they mix with the so-called secondary air supplied to this zone. It enters through thin tubes hidden under slotted convectors. Their upper ends are welded into the upper part of the body. Therefore, even with a completely closed ash pan and feed and chimney gates, the flames still slip through.Only the nature of the flame is different: it "dances" and has a bluish color.

Chimney outlet

This is one of the few stoves in which the chimney can go both up and back. Both are not ideal:

- If you bring the pipe up, soot and condensate will fall into the furnace and burn. But it may happen that a plug forms somewhere. And then, cleaning the chimney is problematic: it needs to be disassembled, which is difficult when sealing the seams.

- If you bring the pipe back, and then lift it up through the tee, then you can hang a glass for collecting condensate at the bottom. The same bend can be used to clean the chimney. In this case, there is no need to disassemble it. But it is important to remember that narrowing the cross-section of the chimney is unacceptable: it must be equal to or greater than the outlet of the pipe. This is the only way to ensure normal traction.

The chimney can be directed upward or to the side

This function - the ability to change the direction of the chimney - is really convenient. You can easily adapt to an existing chimney. The direction is changed by turning the nozzle without any additional measures.

Replaceable fuel chamber protector

The average lifespan of metal furnaces is 5-7 years. Then the most loaded part burns out: the firebox. To extend the period of operation, removable protective plates were built into the Fire-Battery oven. They cover the most problematic parts of the firebox and are easy to change. The protection is held by metal clamps, can be removed and installed without any special tools. You may need a screwdriver to remove - bend the locking plates. They are folded so that the protection stays in place during transport. After replacement, there is no need to bend them.