During a major overhaul, most owners of apartments or country houses think about replacing heating radiators. Previously, in almost all houses, cast iron batteries were installed, which were heavy and did not differ in external presentability. At the moment, technologies are developing, it became possible to produce high-quality products for heating from aluminum.

Such products fit perfectly into the interior due to their attractive design, while they are characterized by increased heat transfer, providing reliable heating of the home. On the Russian market there is a wide range of aluminum radiators "Thermal", which can be matched to any type of heating system.

Features of "Thermal" radiators

The production of batteries of this company is carried out by JSC "Zlatoust Machine Building Plant". The key advantage of heating products is that they are developed taking into account the operation on the territory of Russia.

Production technology

For the manufacture of batteries, a corrosion-resistant aluminum alloy AD 31 is used. Produced by extrusion. Separately form vertical columns and horizontal collectors. In the columns, the latches are squeezed out by stamping, which are connected to the grooves in the collectors. This type of lock provides high strength characteristics.

Double rubber sealing rings are responsible for reliable tightness. Two grooves are machined near each vertical channel located in the horizontal manifold. O-rings made of heat-resistant rubber are placed in them.

The next stage of the assembly is the molding of the radiators into one unit by means of a press. This makes the products non-separable, that is, they cannot be repacked. They are delivered ready-made straight from the factory. It only remains to install them correctly.

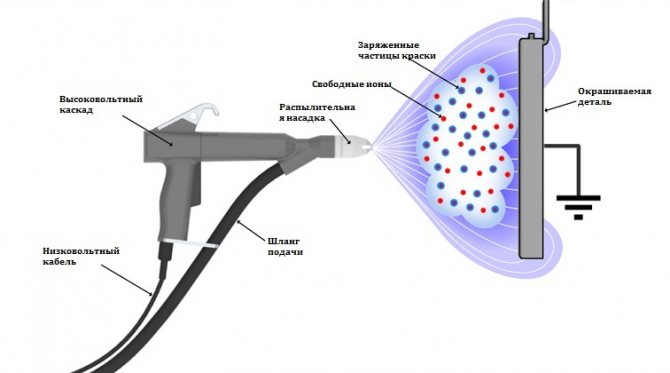

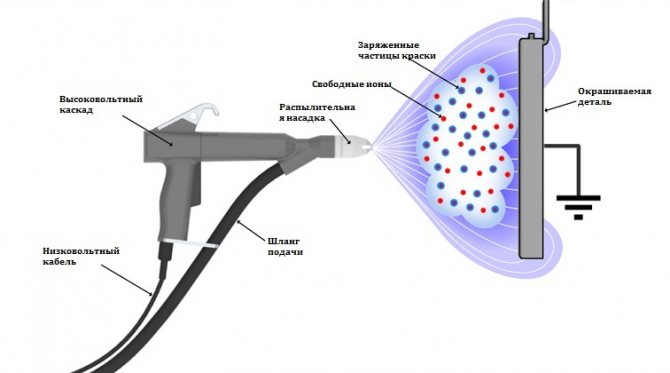

For the outer coating of heating devices, powder paint is used. This stage of production is carried out in an electrostatic field. The advantage of this technology is that the resulting coating is highly resistant to mechanical stress. In addition, a special pigment is added to the base paint, which protects the coating from discoloration during operation or under the influence of ultraviolet rays.

Benefits

Termal radiators are often installed in Russian heating systems. Due to their performance characteristics, they confidently occupy a leading position.

Let's highlight the main advantages of the product:

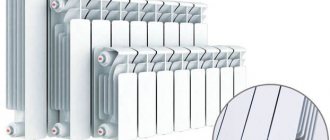

- Compactness. The thickness of the devices is no more than 5 cm. This makes it possible to install them not only on open walls, but also under narrow window sills.

- Guarantee. The warranty period is 5 years.

- Compatibility. During installation, batteries can be connected to communications made of various materials, such as plastic or steel.

- Installation. The installation process is straightforward, and it will be even easier due to the unified thread of the elbows.

- Corrosion resistant. Compared to cast products, high-quality aluminum products are able to last longer without becoming rusty.

- Aesthetics. Products are coated with powder paint. The original appearance of the products will be maintained for a long time.

- Smoothness of channels. Thermal batteries have no technological “pockets” where sludge deposits could accumulate.

- Good level of thermodynamics. Thanks to this, it is allowed to embed any heat-regulating devices into the structure.Due to the "small capacity" of the devices, expenses on the coolant are saved.

- Adaptation to Russian realities. Radiators successfully show themselves in domestic central heating systems, where the acidity of the coolant (pH) varies from 8.3 to 9.5.

disadvantages

Aluminum heaters have certain negative qualities, due to the characteristics of the material used.

There are such disadvantages:

- Ventilation. The system is constantly undergoing chemical processes that cause the formation of air. It needs to be played off from time to time.

- Threaded connections. They are considered to be the weakest points of the instruments. If a water hammer occurs, there is a possibility that the tightness will be broken in these places.

By and large, these are not too serious disadvantages. In addition, the manufacturer takes into account all the operational features when modernizing its own products.

Aluminum radiator TERMAL 500 (Code:)

"THERMAL":

aluminum radiators for hot water heating

patented

certified Sectional radiators "Thermal" are made on the basis of

hardened and artificially aged aluminum

extruded profiles made of aluminum-magnesium

alloy 6063 (analogue of AD-31T6, with components Al-98.5%;

the rest are Mg, Si, Fe, Cu). Extrusion is performed on

press with an effort of 2000 tons, which gives the received

profile high hardening, solidity of the material, "mirror" cleanliness of the inner channels and outer surfaces. These defining properties are harmoniously implemented in a product with a high technical level, surpassing analogues in all parameters, or at least not inferior to them.

The overwhelming majority of imported analogs are made of cast silumin alloy. Casting material allows to diversify the product design, but in terms of technical and operational characteristics it loses to the structural profile used for "Thermal". In addition to the fact that silumin in circulation is a very fragile material, the microporosity of its casting is more critical for a radiator, which reduces the margin of static strength and, as a result, the resistance of the device to water hammers, which are not uncommon in the conditions of Russian central networks. GOST 31311-2005, for cast products, the safety factor is divisible by 3, which is most of these representatives simply do not have... Due to the used high-strength material and rational design containing only 3 main parts, the Thermal radiator has a safety margin even higher than that established by this standard. The scheme of the device is made as a monolithic structure, in which the connecting fittings of the sections are pressed into the mating sockets of the collectors, and the sections themselves are rigidly connected to the collectors due to stamped latches.The design without damage perceives not only "outrageous" operational water shocks up to 60 atm, but it is also extremely unpretentious in everyday life with possible loads from throws and distortions, and strong and plastic ribs that protect the "vital" parts in case of accidental impacts, allow you to give the product an "anti-vandal" look. All this makes the use of "Thermal" universal for both low-rise and high-rise buildings.

According to the standards RD153-34.0-20.501-2003, alkaline reagents are added to the coolants, limited by the pH value pH = 8.3-9.5. The "Thermal" radiator, made of an extruded profile, according to this factor, which is the most critical for the operation of aluminum devices, has been tested and operable at pH up to 10. In this respect, it is "on a par" with bimetallic and panel devices and out of competition with imported cast analogs, generally unacceptable for use in our central heating, as having a pH limit of ≤8.

High level of reliability and durability of "Thermal" devices is based on a unique 2-level system of "blocking leaks", in which the sealing of the joints is carried out both by pressing in the unions of the sections and the blocks of rubber rings installed on them. Connections even harden over time due to the "tightening" of the joints with sludge deposits. Besides, constant channel cross-section and smoothness of their walls minimize the processes of sludge deposition and dissociation of the coolant as much as possible, which makes the operation of Thermal devices guaranteed to be stable, unlike its competitors. So much for bimetallic appliances and convectors(with mechanical contacts of heat-carrying and heat-dissipating elements) typical problems of "thermal loosening" of the joints and in this respect they tend to have a reduced level of durability. Cast aluminum radiators have, in turn, a different lowering level of reliability.

"Flaw" associated with the roughness of the internal channels and their variable cross-section. This leads to progressive sludge deposits, uncontrollably deteriorating hydraulics and heat transfer., and the process itself, moreover, due to the nature of the alloy, is accompanied by another nuisance in the form of enhanced dissociation of the coolant with the release of hydrogen radicals, which threaten to explode the device and, consequently, make the operation “capricious”.

Thermal radiators are extremely compact and, accordingly, due to the small working volume of the coolant have high thermodynamics, which gives them the possibility of optimal combination with any automatic heat-regulating devices and, as a result, allows you to build an energy-efficient heating system. At the same time, the "small capacity" of the devices, creating savings in the cost of the coolant, is an additional incentive for the use of products.

Production of "Thermal" radiators organized at a high technical level andcertified according to the international quality system ISO 9001-96... The factory system, which ensures the quality of fulfilled orders in the space sector, is guaranteed to accompany the presented products at the proper level. Each device undergoes acceptance tests (36 atm in pressure), acceptance is certified by the branding of the device and the OTK mark in the factory accompanying technical passport, which certainly certifies the quality of the goods. And here imported analogs are not equipped with a factory registration certificate, which means that in violation of GOST 31311-2005, they do not have acceptance marks and, accordingly, do not have reliable data on both the manufacturer and the reliability of the product.

Radiator «Thermal "in the same type row also stands out with commodity" exclusives ". Hisglossy enamel based on powder paint, especially durable in operation due to high adhesion to “mirror” painted surfaces, contains "snow pigment", which protects the freshness of the coating from aggressive effects ultraviolet light for the entire service life... Competing products, in the main assortment, have standard "milky" coatings, prone to "yellowing" during prolonged "attack" of sunlight. Thermal noticeably stands out for its “flat” design (thickness 52mm) with a modern “laconic” design. This compactness is especially valuable when placing the devices on an open wall or under narrow window sills. The radiator is lightweight and "assembly" symmetrical, has a single thread of G3 / 4 (right) connections with an inlet chamfer for a standard O-ring of unified fittings, which greatly simplifies design and installation work. A typical imported analog is usually 1.5-2 times thicker, is installed only in a certain position and requires a special set of connecting elements for installation with dissimilar threads (left / right).

Thermal radiators are modern, highly efficient products that meet all professional requirements for heating devices and are reasonably intended for use without restrictions in all central heating networks, in closed and local systems, compatible with pipes made of plastic, steel, non-ferrous and combined materials.

Technical specifications

• heat carrier: water according to RD153-34.0-20.501-2003 standards

• pressure (work): up to 2.4 MPa • strength: St. 6.0MPa

• pressure (isp): 3.6MPa • thickness: 52mm

• temperature (work) up to 105 * С • step of sections: 84mm

• temperature (max) up to 130 * С • assembly nomenclature: 300; 500mm

• power 1 sec: • nomenkl. step: (each height) 3… 16 sec

(height 300) 105W • volume: up to 0.123l / sec

(height 500) 161W • weight: (corresponding to 300; 500) 0.7; 1.0kg

What is the difference from foreign analogues

If you compare Thermal batteries with similar aluminum products, you can find many differences.

Products differ in several ways:

- Coloring. A pigment of increased whiteness is additionally added to the powder coating of Thermal radiators. As a result, the color of the radiator is glossy and resistant to mechanical damage. Many traditional models, on the contrary, are covered only with milky paint, which fades over time, acquiring a yellowish tint.

- Strength. The devices are not inferior in this indicator to bimetal products or convectors. Thanks to their rational design and modern alloys, the batteries successfully withstand 12 MPa (120 atmospheres) water hammer. Analog products are usually made from silumin, which is not as strong.

- Material. The basis for the Termal radiator sections is hardened extruded profiles. The process of their manufacture is carried out using a press with a pressure of 2000 tons. This method makes it possible to produce mirror-clean external and internal surfaces of radiators with a uniform structure and increased strength. Similar products are made from silumin alloys. Complex castings can be made of them, but this material has micropores, which makes the product more fragile.

- Life time. Pressed products can serve for about 20 years, which is confirmed by field tests in accordance with the ABOK standard, clause 5.1.9.

- Design. "Thermal" produces monolithic batteries with the number of sections from 3 to 16 units.

- Thickness. This indicator for devices is only 52 mm. As a result, the overall weight of the product is reduced, which makes installation work easier. As for imported analogs, they are 1.5–2 times thicker and for their installation it is necessary to comply with certain requirements.

- Quality control. Thermal radiators are necessarily tested with a pressure of 36 atmospheres, after which a special stamp is put on them. Thanks to modern technologies, every stage of production is strictly monitored. ISO certification only increases customer confidence in the company. Imported products often lack factory documentation, so it is difficult to judge the quality of such products.

- Hydrogen exponent pH. Batteries of the Russian manufacturer can operate in a working environment with pH = 10. In centralized heating systems, this indicator varies from 8.3 to 9. For imported heating devices, the alkaline value threshold is set at no more than 8.

- Tightness. Thermal products are characterized by a modern two-level sealing system. Along with the use of rubber O-rings, the fittings are also pressed in. During operation, such a structure is covered with silt, which further increases the tightness. Similar imported appliances use flat gaskets, which are considered less reliable.

From this we can conclude that domestic batteries are ideal for central heating systems.

Prices for the Thermal range of radiators

thermal radiators

Thermal 500 [161W] All manufacturers: Thermal

Brick stoves / fireplaces

Ready-to-assemble kits

Wood-fired heating stoves

- Portable wood burning

Wood-burning stoves

- METAFIRE / ARDENFIRE (Russia)

Inserts / Mantels

- Cladding METAFIRE (Russia)

Wood-burning sauna stoves

- METAFIRE (Russia)

Boilers and boiler piping

- Long burning LIEPSNELE

Chimneys and their components

- Stainless steel SDS D115 / 180-30

Electric heaters, remotes

- Remotes / Control Units

Electric fireplaces / Bio fireplaces

- Fireplace set 3D HELIOS / OPTIMYST

Installation, maintenance, repair, spare parts

- Thermal protection, thermal insulation

Products for baths and saunas

- Tanks and heat exchangers

Grills / Braziers / BBQ / Tandoor

- Braziers / Grills / Barbecues

Samovars / Distiller / Smokehouses

- Samovars Tula

Accessories / Decor

- Weather vane

Water heaters / Washbasins

- Gas BALTGAZ

Warm floors / Regulators

- Film HOT-FILM (Korea)

Cannons / Heat curtains

- Gas cannons BALLU

Convectors / Heating / Dryers

- Heaters SOLAROGAZ

Radiators / Towel dryers

- Aluminum radiators

Grill houses / Gazebos / Baths

- Gazebos

Overview of models and their cost

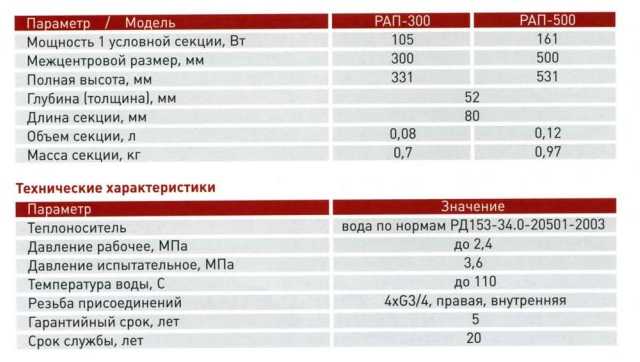

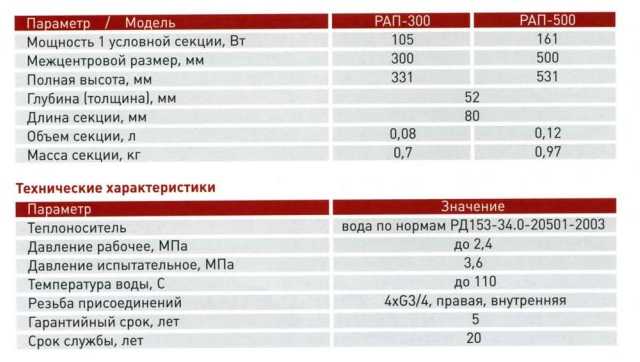

At the moment, the manufacturer produces 2 models: "RAP 300" and "RAP 500", which differ in technical characteristics.

"RAP 300"

The exact height of these devices is 331 mm. The minimum number of sections is 3, and the maximum is 16.

Characteristics:

- withstanding pressure - 24 atm. (short-term allowed 35 atm.);

- coolant temperature - no more than +105 ° C (briefly withstand up to +135 ° C);

- section length - 80 mm;

- power - 0.114 kW;

- section capacity - 0.08 l;

- center distance - 300 mm;

- depth - 52 mm;

- section weight - 0.7 kg.

Thanks to these characteristics, the devices are successfully installed in apartment buildings. Both vertical and horizontal wiring is allowed. There are no pressure restrictions for individual heating, since the indicator rarely exceeds 2-3 bar.

"Thermal 300" battery is 1.5 times less powerful than the model 500. Its average cost per section reaches 322 rubles.

"RAP 500"

The service life of this model reaches 20 years.

Specifications:

- section power - 0.161 kW;

- center distance - 500 mm;

- section volume - 0.12 liters;

- height - 531 mm;

- depth - 52 mm;

- length - 80 mm;

- section weight - 0.97 kg.

The performance characteristics of domestic batteries "Thermal" are at the level of the best world standards. The average market price for one section is from 350 rubles.

Characteristics and scope

Batteries are produced in two standard sizes - with a center distance of 300 mm and 500 mm. Total heights are 331 and 531 mm, respectively. The center distance is displayed in the title. They are called RAP 500 and RAP 300.

They differ in a very shallow depth of 52 mm, low water capacity. In one conditional section (conditional, because it is non-separable) 0.12 liters for the Thermal 500 and 0.08 liters for the smaller one.

The thermal power of one section is 161 W for the higher model and 105 W for the lower one. The operating temperature of the coolant is + 100oC, with a short-term increase to +130 oC (no more than an hour in one heating season). The sections are completed in one-piece heating batteries. The minimum quantity is 3 pieces, the maximum is 16 pieces. A sufficiently small step allows you to select the heat output with a fairly high accuracy.

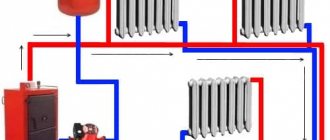

The pressure is very high: working pressure up to 24 bar, test pressure up to 36 bar, breaking pressure 120 bar. The hydrogen activity of the coolant Ph is not higher than 9.

All these characteristics make it possible to use Termal aluminum radiators for installation in apartments in multi-storey buildings. They can stand both in houses with vertical and horizontal wiring, the type of system is one-pipe and two-pipe. In order not to make a mistake in the choice, you first need to make sure that the network parameters meet the specified standards. Go to DEZ, DEU, etc. and find out the Ph, working and test pressure and temperature of the heating medium for your home. Compare the obtained data with the technical characteristics from the table. If all of them suit you, you can buy.

In individual heating, there can be no pressure restrictions: in such systems, it rarely exceeds 2-3 bar. They are compatible with any boilers, only when working with solid fuel units, you need to monitor the temperature of the coolant: it should not rise above + 100oC. It is not recommended to install them in a network with a copper heat exchanger; the use of copper pipes is prohibited.

Technical characteristics of "Thermal" aluminum radiators

Nuances and installation rules

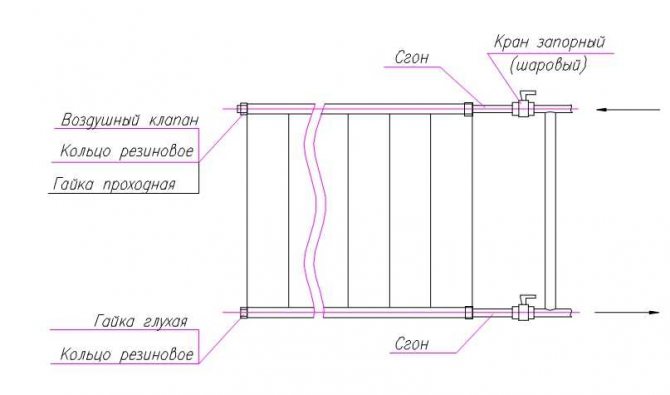

Thermal radiators can be connected to steel, polymer and metal-plastic pipes. To facilitate operation, the manufacturer recommends to additionally install shut-off valves. To regulate the level of heat transfer, manual or automatic thermostats are used, as well as control valves. Each battery must be equipped with an air vent valve.

Choosing control and shut-off valves, it is better to give preference to chrome-plated or galvanized models. Uncoated brass and bronze cannot be combined with an aluminum alloy due to the high copper content, in which case the elements of the heating system are destroyed faster. Copper, in contact with aluminum, forms a galvanic pair, which leads to electrochemical corrosion.

It is not recommended to use acidic silicone products during the sealing process. The best choice is neutral. Linen tow or FUM tape can be used as a reel. Aluminum is a soft metal, so you do not need to apply excessive force when installing it.

There is no need to remove the protective film from the radiator during installation. Only the places where pipelines are connected and brackets are installed are cut off. The film is removed at the end of finishing work. Before the installation itself, it is necessary to level and plaster the wall, and its upper edge should be strictly horizontal.

Also observe the installation distances:

- From the floor - 8-15 cm. If you set it lower, then dust will accumulate under the battery, and if it is higher, cold air will be trapped from below.

- From the window sill to the top of the radiator - at least 10 cm. If the distance is less, air circulation will deteriorate.

- From the wall to the back of the battery - 25 to 35 mm.

It is these distances that allow heating devices to most effectively perform their task.

DIY installation

Termal radiators are mounted in a slightly different way than their counterparts: they are not hung over the collector, like sectional products. The rear panel of the batteries is equipped with special holes for brackets: 2 at the bottom and 2 at the top. This must be taken into account when marking, adhering to a horizontal installation.

The installation procedure is as follows. The places where the brackets will be attached are marked on the wall.

In these places, holes are drilled into which wooden plugs or dowels are inserted.

Brackets are attached. For this, screws with a length of 35 mm and a diameter of at least 6 mm are suitable.

Holes are made in the protective film of the radiator in those places where the fasteners should be. The battery is suspended on brackets.

Shut-off, control valves, air vents, plugs, adapters are installed.

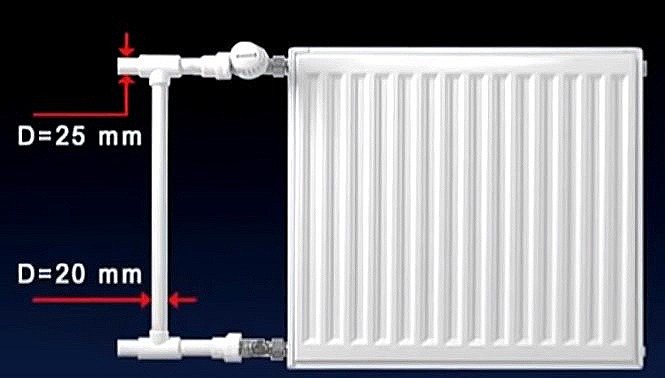

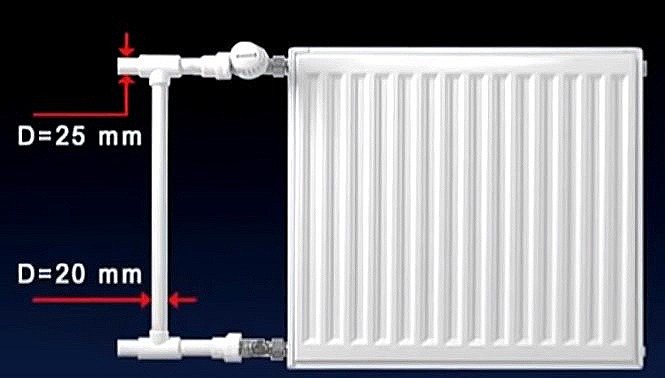

If the equipment is connected to a one-pipe system, then a bypass should be installed between the supply and return - a pipe one diameter smaller.

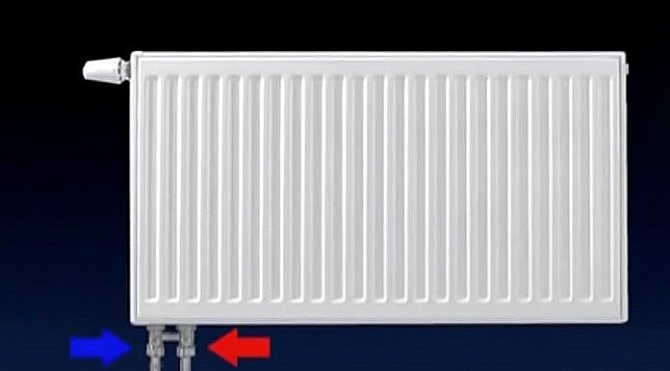

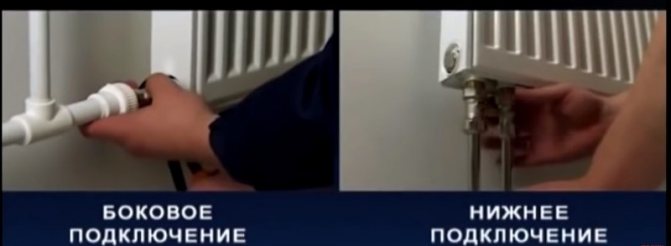

The maximum heat transfer is achieved if the supply pipe is connected from above, and the return pipe is connected to the other side of the device from below.

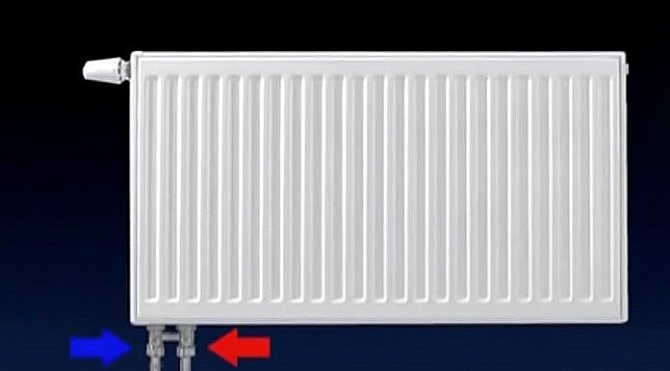

When installing with a lower connection, the supply pipe is installed in the branch pipe located closer to the middle of the radiator (red arrow).

The connection can be side or bottom. Most often, the batteries are connected vertically.

In order to maintain the product warranty, the installation of radiators should be entrusted to specialists who are licensed to perform the work.

Gas and electric stoves Dream

This category of goods is also very popular. The range includes:

- electric stoves for 4, 3 and 2 burners;

- gas stoves for 4 and 2 burners;

- tabletop electric and gas stoves;

- tourist plates.

The manufacturer values its half-century history and supplies only reliable equipment to the market.A significant advantage of this technique is its availability, because you can find Dream stoves and find a service to repair them in any, even the smallest city of our country.

In addition, there are a number of advantages that Zlatmash brand plates have:

- Price. If you want to buy good cookware inexpensively, then the Dream cooker is the perfect choice;

- Coating. These products are equipped with a unique coating that is quite easy to clean from various contaminants and will serve you for many years;

- Profitability. These tiles consume very little electricity compared to their imported counterparts. And this quality does not at all affect the heating rate of the burners.

Recommendations for use

Once again, it should be noted that Thermal radiators are produced non-separable, that is, they cannot be sorted out, otherwise it will lead to a breach of tightness. If the drain valve on the air vent is closed, do not completely shut off the supply line. It is also not recommended to leave the battery unfilled with coolant, in such conditions corrosive processes are activated.

You need to bleed air from the system 2-3 times a season. If there is an automatic air vent, no action is required.

So that the battery is not damaged during the pressure testing of the system in a multi-storey building, it is allowed to disconnect it for a while. Before this, the ball valves are closed and the air vent valve is unscrewed.

It is recommended to clean the outer surfaces of the radiator 2-3 times a season. For this, only soft materials and products are used that do not contain abrasive inclusions. Find out the stove with a hob by the link.