What materials are needed to insulate a cold floor in a private house

Consider the most popular heaters:

Mineral wool. The most common material for home insulation. In addition to low cost, it has ease of installation, good sound insulation, low thermal conductivity. Disadvantages can scare off a potential buyer. High vapor permeability without installing waterproofing calls into question the advisability of using mineral wool for house insulation. In addition, rodents liked it.

Ecowool

Low cost, environmentally friendly material, good thermal insulation attracts the attention of buyers. But the disadvantages are the same: moisture permeability, a delicacy for rodents and flammability.

Expanded polystyrene

Good heat insulator, highly resistant, does not allow moisture to pass through. The disadvantage is the same flammability. When burned, it emits a lot of harmful substances, therefore it should not be installed in a residential area.

Plywood, sawdust, chipboard. Quite popular heaters. They are harmless to the premises, since they do not emit poisons during combustion. There are flaws in thermal insulation and flammability, but otherwise acceptable for installation. The least popular: glass wool (inconvenient to work, harms the body), expanded clay (has too thin a layer for thermal insulation), polystyrene (high fire hazard).

When choosing a heater, each owner should focus on many indicators: what is your area of the room, are the windows insulated, the interior of the house, the material component, etc.

But the most important thing is that the insulation must qualitatively fulfill its characteristics declared by the manufacturer and warm the residents of the room with warmth and coziness, give comfort and serve for a long time.

https://youtu.be/N6l1YqhAxC0

How to insulate a cold floor in a wooden house

Many owners of private houses have to solve the problem of keeping warm. This is one of the main conditions for a person's great well-being in their own home. What kind of comfort in a house can we talk about if it has a cold floor? How can you insulate the floors in a wooden house with your own hands? What materials should I prefer?

Different materials are used to insulate the floor in a wooden house. These can be artificial products or natural products made from natural ingredients. each of them has its own advantages. The main condition when choosing a specific insulation is its ability to retain heat inside the room as much as possible and provide a comfortable temperature for the feet of the inhabitants of the house.

The following types of heaters are most in demand among consumers:

- types of construction wool: mineral, glass wool, ecowool;

- synthetic: polystyrene, expanded polystyrene;

- bulk: expanded clay, sawdust (shavings).

Depending on the building characteristics of the house, the financial capabilities of the owners and the complexity of installation, one of the types of material is chosen to insulate the cold floor in a private house.

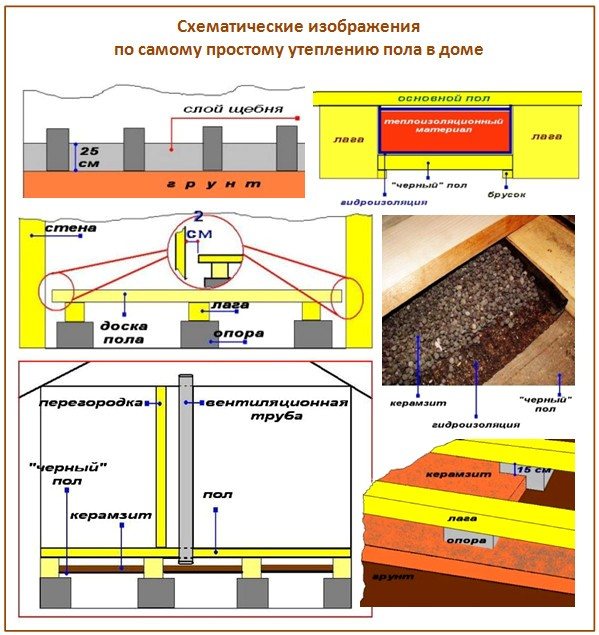

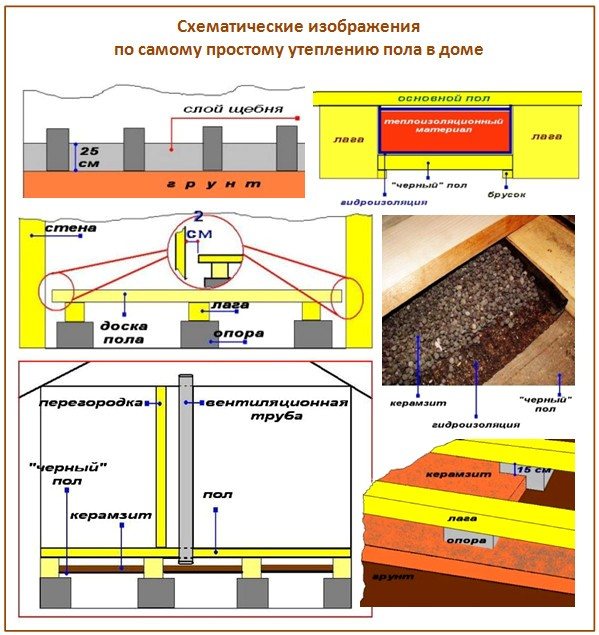

Do-it-yourself floor insulation

It is quite simple to make a wooden frame from logs (wooden slats). Their size is chosen based on the thickness of the insulation.

In addition to a heat insulator, a log will be needed:

- fasteners for a wooden frame (dowels, screws, anchors);

- mortar glue, mastic;

- waterproofing layer (in the simplest version - dense polyethylene);

- construction foam (if necessary, to fill gaps in hard-to-reach places).

The bottom layer of waterproofing is laid on the concrete base, after which the logs are attached to the concrete.

The step between the lags may depend on the cutting of the heat insulator; the optimal distance between the bars is 60 centimeters. Logs in apartments above damp basements can be additionally treated with water-repellent impregnations.

A heat insulator is placed in the intervals, which is covered from above with an outer layer of polyethylene.

A wooden base of the floor (final floor covering) is attached to the logs. Ventilation gaps are left near the walls.

Loose insulation

Expanded clay from all types of similar materials will be the most affordable. However, it also has the most significant drawback - the backfill layer must be at least 15 centimeters, which will automatically reduce the volume of the room. In apartments on the ground floors at the back or above the openings, this type of heat saving is nevertheless popular. In addition, with expanded clay comes out a good insulated floor screed in the apartment. In order to make it, the filled-in expanded clay is poured with concrete. A lightweight and very good heat-retaining structure is created, which is lightweight.

If you are deciding how to insulate the floor in the apartment above the arch or on the ground floor and the height of the walls makes it possible to slightly raise the floor, it is difficult to find a cheaper and more functional material. However, there are also modern analogues of expanded clay, allowing you to create a less thick layer of backfill. They consist of polymer granules connected with a special binder. After filling and leveling, the granules stick together and the composition hardens - an even surface is obtained, which must be decorated with a finishing coating.

Floor insulation in an apartment on the ground floor

Cold floors are typical when living on the ground floor in an old housing estate. This is due to insufficient thermal insulation of the basements.

In such houses, no measures were taken to improve waterproofing, therefore, it pulls from below and dampness.

Floors in apartments (linoleum, laminate) are laid directly on the concrete floor, without an air gap.

Ground floor apartments suffer the most from the cold, giving off heat to the upper rooms and not receiving heat from the bottom. The best methods of insulation are active (using heat, electricity, water) warm floors. In many cases, it is sufficient to improve the floor by installing an insulating layer.

Floor insulation

The second place is occupied by dampness. Cold air enters the subfloor through the vents and settles on the logs. The insulation meets the enemy with his chest, letting the frost into the house.

First of all, give the insulation a "shield" - a polyethylene plate. It blocks the condensation process, keeps it dry and warm. As a last resort - give up the air. You can also ventilate the subfloor through the grate.

Next, insulate the foundation, block the air vents, clean the subfloor from debris and damaged heat insulator, fill the floor with sand, tamp and level it, cover it with a waterproofer, observing tightness, tighten the entire area with foil, and seal the joints with the wall with tape.

Be sure to get rid of the rodents. Tiny mice dig impressive tunnels for natural ventilation.

The next possible reason is the lack of insulation. A common case is an unscrupulous construction team that pocketed part of the material or finances for it. Take a ruler, measure the insulation layer in the house and search Google for the norm. Lacks? Open and insulate.

The foundation is to blame. If heated floors are installed in the house, they heat the foundation, and he, in turn, heats the street. To prevent heat loss, the foundation is sheathed with several layers of Penoplex around the perimeter.

What to do if the floor in the apartment is cold

For starters, you can complain about cold batteries. But still, the way to solve this problem was and remains - to isolate and insulate the floor.The essence of insulating materials is in their thermal insulation properties, which do not allow heat to escape outside the apartment. There are several options for insulation, consider the popular ones.

- Bulk materials. These include expanded clay, shavings and wood concrete. They have high thermal insulation properties and are relatively inexpensive.

- Glass wool / mineral wool (mineral wool). They are also effective in floor insulation, while the fireproof material is not subject to fungal contamination and is hygroscopic (with mandatory vapor barrier).

- Expanded polystyrene or polystyrene. It has its advantages: it is moisture resistant, does not ignite and does not undergo deformation, has sound insulating properties and retains heat.

It is not possible to unequivocally answer the question of which material is better, since it is necessary to proceed from financial capabilities, the type of apartment and premises in it and their operational qualities and loads. If the apartment has wooden floors, then it is better to use mineral wool as insulation. This will save money and time. The only caveat is that polymer insulation (penoplex) is not suitable for wooden floors due to the increased flammable properties of both materials. It is more effective to use expanded clay on such coatings.

More often found in urban multi-storey panel buildings - apartments with a concrete floor. It is a cold material in itself, so in winter it can be cold in the apartment, plus leaking joints between the plates, as a result - the floor becomes icy. It is interesting to know that 20% of the heat loss from the total heat loss is precisely the cold floors in the apartments.

In the corridor and living room, the floor can be insulated using expanded polystyrene, and in the bedroom and nursery it is better to use loose wood material.

If the floor in the apartment is not very cold, what to do without resorting to repair work with insulation. There are alternatives:

- Lay a rug or carpet. They have a low coefficient of thermal conductivity, the greatest insulation properties of coatings made of natural wool.

- Cover the linoleum on a felt or jute backing, or on a foam base.

If you decide to put a laminate in the apartment, then before laying it is necessary to put a special cork material, then you will not have to wonder why there is a cold laminate in the apartment, and what to do.

So, in order for the floor to have a comfortable temperature, it is not necessary to use expensive heating structures, it is enough to correctly insulate it when using available materials. Find out why the batteries are cold at the bottom and hot at the top.

Reason number 5. Laminate

Although laminate flooring seems warmer than tiles, children won't play on it either - it's unpleasant. Why is that? It's all about the finishing layer - this is a decorative film, not a cut of natural wood. And it has a higher thermal conductivity. In short, cold laminate is a common problem. And it is usually solved in two ways: to put a technical cork under the coating, which has the property of retaining heat well, or -.

The fastest and most reliable option, of course, is to lay a floor heating system. At least in the absence of cracks and dampness, the floor will not feel cold. Just keep in mind: the "warm floor" system does not mean that your coating will just heat (the exception is ceramic tiles), the discomfort will simply disappear, and nothing more.

The underfloor heating system is good not only because it is pleasant to walk on such a floor barefoot and moisture evaporates easily, but also because some heat will keep even when the electricity is turned off.

What else can you do? If possible, if you installed this covering using the locking method, lift it up and install the underfloor heating system. If it's glue, then don't touch it.Instead, pay attention to the heating system: organize it lower than it is, attach IR heaters to the walls - they warm objects, not air, according to the manufacturer.

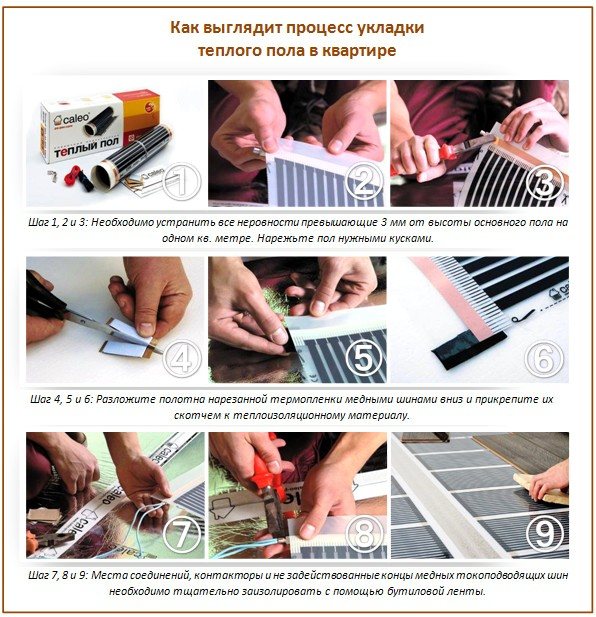

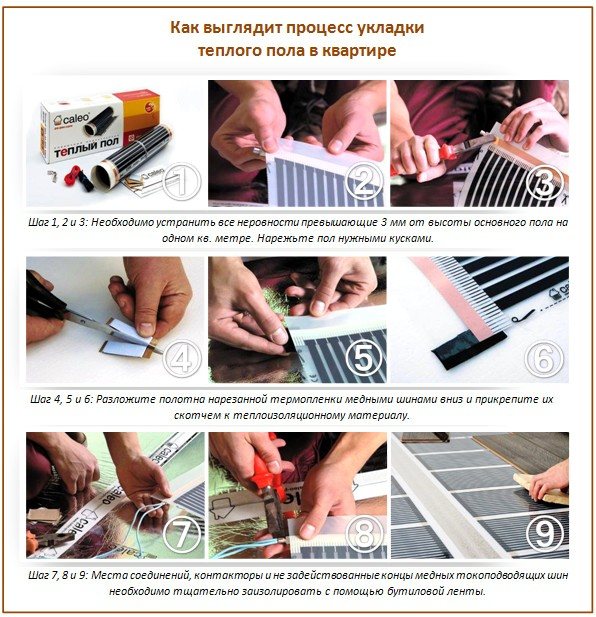

Installation sequence

- The infrared film is laid out on the planned areas, fixed to the floor with a stapler or tape along transparent edges that do not have a built-in wire.

- Recesses are made in the wall. Place the cable from the thermostat to the thermostat.

- The places on the film in the connection area are thickened, for them it is necessary to create artificial technological recesses for them.

- The starting point for laying is on the opposite side of the power connections. A free space of 20 centimeters is left from the walls.

- Connect the copper ends to the thermostat using the supplied cable and terminals. Secure with pliers and isolate.

- The clamp is placed between the film and the wire. The IR strips are connected near the wall. When building them, a wire of the same color is connected to each other, followed by insulation, and additional fastening with tape.

- The cable is routed inside the corrugation. It is closed with a hermetically sealed foil, protecting it from moisture.

- After completing the installation, they check the operability of the entire structure using a portable sensor.

Useful video on laying an electric floor

Cold floors in a private house what to do? - Home Craftsman's Guide

Are cold floors the first and worst impression of your day? Everything can be corrected. It is only important to correctly "diagnose" the problem, because the matter is not always in the absence of a "warm floor" system or the poor location of the room - everything is much more interesting. Now we will analyze the main causes of a cold floor and how to fix this problem.

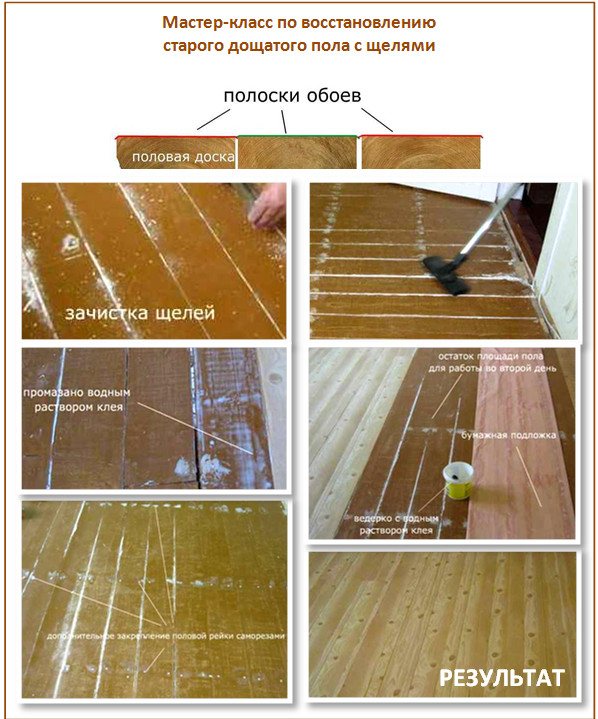

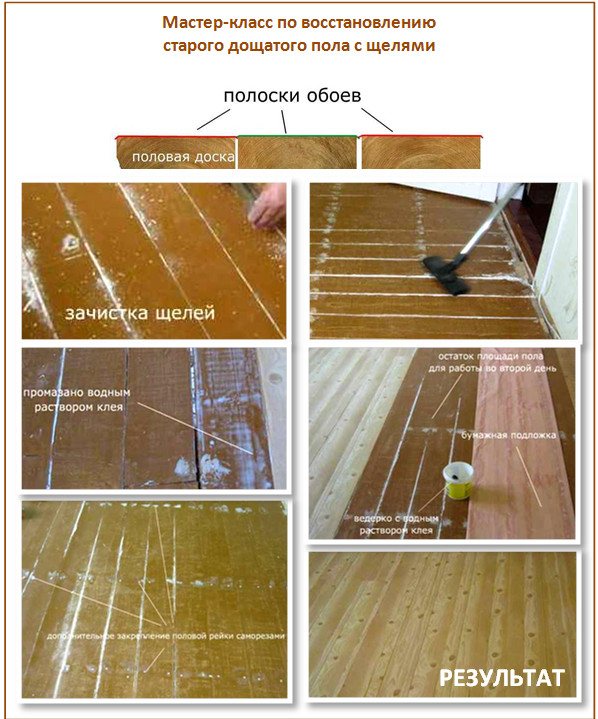

Reason # 1. Slots

The first and most common culprit for cold floors is crevices. So what if your dacha has exactly the same floors? Try this interesting option, which was especially popular back in the days of the USSR. Cheap and cheerful, as they say:

- Step 1. Cover the gaps between the boards with putty. Yes, you can use the most common store, paint it with regular floor paint and leave it like that - but it won't work. The fact is that a person presses on the floorboards with his weight, and they eventually bend - which is why both the putty and the paint fly off quickly enough. Therefore, we make the putty in our own way: knead finely sifted sawdust on PVA glue (for furniture). It is with this composition that fill the gaps, having previously lubricated the edges of the floor slats with the same PVA. Glue "Stolyar" is also suitable due to its water resistance.

- Step 2. Now, with an ax blade, cut off the protruding old blobs of paint on the floorboards and lightly sand the entire floor with medium-grained sandpaper.

- Step 3. In some problem areas, fix the boards with self-tapping screws. Just "drown" the caps themselves, and putty the holes with the same mixture as the slots.

- Step 4. Vacuum thoroughly the entire surface.

- Step 5. Now get a thin paper wallpaper with a wood texture (any other option is possible, of course).

- Step 6. Roll out the rolls in a convenient place and cover with a thin layer of parquet varnish (dilute it with a little solvent). This is necessary in order for the wallpaper to turn out to be more durable when wetted with PVA glue, also liquid diluted with water. In addition, otherwise the texture of the wallpaper may also wear off during smoothing. And stains from accidental touches will appear. By the way, it is the textured surface that we paint.

- Step 7. Now we cut the individual sheets of wallpaper - as wide as each individual board.

- Step 8. Apply glue to the boards and place the prepared sheets. If the gap is still noticeable, then slightly press the paper into it. But each strip must overlap the next. By the way, if the varnish bursts between the stripes, this will only add decorativeness to the entire coating, imitating a real plank floor.

- Step 9.Press the paper strips tightly and smooth them with a clothing brush to remove air bubbles.

- Step 10. Remove excess glue with a clean cloth.

- Step 11. Leave the new floor to dry for at least three days. After that we cover it with three layers of parquet varnish.

This is how it looks:

But what to do when the gaps are too large:

Such a floor will serve you surprisingly long enough, but you will forget about drafts through the cracks forever.

But if things are really bad, do this:

And in the complete absence of funds like this:

Reason # 2. Dampness under the floor

Dampness in the underground can still give a lot of worries. So, already in the spring, damp and warm air enters the house through the vents, and the basement at this time is still cold. Usually, this stream finds its condensation point on the logs, and manages not only to fill the unprotected insulation with moisture, but even hang on it with icicles. And this cold dampness directly touches the floor.

What to do in this case? First of all, protect the insulation from below - at least with the same plastic plate. Secondly, if this happens all the time - and completely abandon the vents, and organize the ventilation of the underground through the grate in the house itself.

https: //www..com/watch? v = 8UAo7FWoPng

You also need to try to somehow insulate the foundation itself with a plinth so that it does not freeze so much for the winter:

By the way, you will be surprised, but your tailed lodgers - mice - also manage to make their moves so that you feel a considerable draft near the walls. Control methods: a cat, an electric cat or an ultrasonic repeller.

Reason number 3. Lack of insulation

When you do everything in the house with your own hands - would it ever occur to you to put half as much insulation under the floor than the instructions are for? Hardly, you will agree. After all, you will freeze afterwards. But it’s easy for a hired construction team.

The floor cake looks decent, everything is done, at first glance, professionally, and the lack of building materials is not so easy to calculate. Especially if you yourself do not understand much about this. But the same remainder can be added to the second client, and everything will also look decent.

But the foreman was paid for two whole sets!

Bottom line: cold floor. What to do? It is easy to check the insulation layer: find on the Internet what layer should be in the material that you have, and check with a simple metal ruler. A clear flaw? The floor will have to be completely opened.

We install additional heaters

If all the measures for insulation and decoration did not bring the desired result, “heavy artillery” comes into play, that is, a variety of additional radiators and convectors, of which there are a great many today. If possible, the most obvious and practical solution would be to replace the old batteries with a newer model with greater heat dissipation, attractive design and temperature control.

Decorative shelf-radiator, Vanixa

In addition to replacing stationary heating radiators, you can use additional options, for example, install a flat convector. Such a convector is wall-mounted and can operate continuously. There is a solid-cast heating element inside the convector, which ensures quiet operation and quick warming up of the room to the required temperature without changing the air humidity.

Convectors are compact, which is very important, Galletti

One of the most advanced heating options today are infrared heaters and panels. Their fundamental difference from other models is that they provide uniform circulation of warm air throughout the room, and not just near the battery itself.This effect is achieved due to the fact that a quartz lamp in the form of a long tube is installed inside the metal case, while you can both equip the room with built-in infrared panels and connect a portable heater.

Compact infrared radiator-bedside table, Infrared

Compact and practical solution - infrared radiator on the ceiling, ATH Italia

If the lack of heat in the house is a temporary phenomenon, for example, before the start of the heating season, it is enough to get a compact electric fan or oil radiator. They are mobile and relatively inexpensive, but they dry the air, which negatively affects health, and consume a lot of electricity. It is better to have this option as an additional safety net in case of a sudden cold snap, and to maintain a constant temperature in the room at the expense of other means.

Portable oil radiators of various sizes, S&P Italia

We have briefly reviewed various options for maintaining a comfortable temperature in the house during the winter. Of course, these decorative techniques are unlikely to replace high-quality repairs, but by combining our various tips, you can easily make winter evenings much warmer and more comfortable for the whole family.

Foamed polyethylene

Perhaps the simplest type of insulation. The roll only needs to be rolled out, after which it is trimmed to the desired size. Separate sheets are glued together with construction tape. Many people, when deciding how to insulate the floor in an apartment under a laminate, choose exactly this type of thermal insulation. The thickness of the roll insulator is quite small, and the quality of heat saving is at a fairly high level. In addition, the laminate layer also partially solves the heat problem.

Basement side insulation

The best solution is to insulate the floor slab from the basement side. In other words, it is necessary to insulate the ceiling in the basement, thus moving the cold and dew point away from the floor in the apartment.

To carry out such work, it is better to make an agreement with the ZhEK. This is usually not a problem. Having received such a permit, you can start thermal insulation work. For this, the following techniques are available:

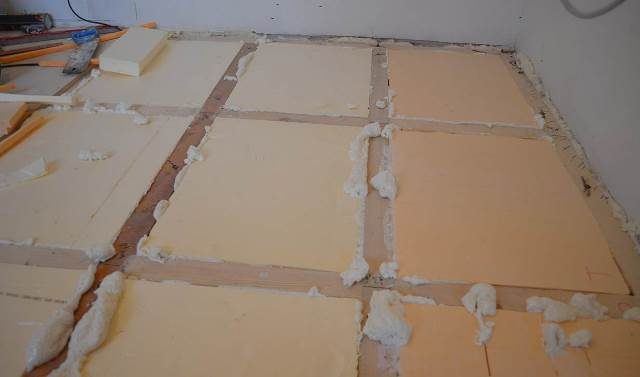

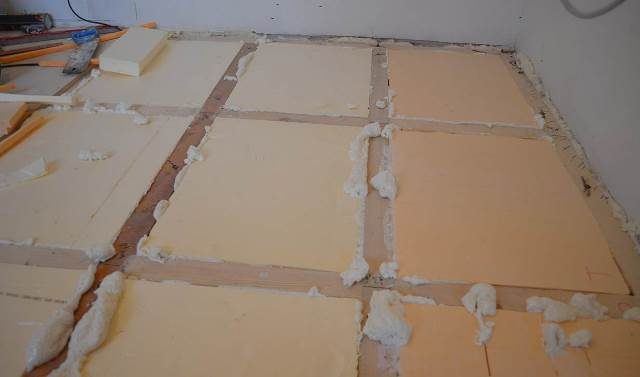

The simplest, inexpensive, but at the same time quite effective method is to make foam insulation. Liquid nails are glued to the concrete base with glue. At the end of the work, all the gaps remaining between the sheets should be filled with polyurethane foam. Since the basement is quite often damp, and the foam has the property of being saturated with moisture over time, it is necessary to waterproof it. To do this, a thick plastic film is glued onto the insulation sheets with the same glue. The edges of such waterproofing must be overlapped at least 10-15 cm.

It is possible to spray polyurethane foam - one of the most reliable and durable insulation materials known today. After hardening, this material has high strength, excellent thermal insulation properties. Also, polyurethane foam does not burn and does not absorb moisture at all. The only drawback of this option is its rather high cost: spraying is carried out using special equipment and requires professional skills of the operator.

The apartment has a cold floor: what to do, expert advice in the photo

Construction work does not always bring the expected result. Quite often, there are situations when the work on the construction of any structure or flooring was performed correctly (appropriate materials were used), and the result leaves much to be desired.

Since the appearance of the product and the quality of installation are good, but the functionality is poor. Situations like this are not uncommon when installing floor coverings, resulting in a cold floor.

Common causes of cold floors

Each unsuccessful installation of finishing flooring, as a result of which the floor turns out to be cold, has its own reasons and "pitfalls". In the process of installing the coating, factors may seem insignificant, but in the end they will play a large role.

Invisible gaps are the cause of cold floors

Cracks are a very unpleasant defect.

If flooring is done in an old private house or apartment, cracks are common, and in order to eliminate all openings through which warm air leaves the room, you need to be extremely careful.

Old coatings need high-quality gaps

Rough flooring in old private houses and apartments was made of wooden planks and cement-concrete screed. The cracks in the screed are visually noticeable and can be repaired with epoxy glue and special repair compounds.

All sealed gaps in concrete must be rubbed with sandpaper and polished, which will allow all areas to be brought under the general floor level.

It is very important to lay the flooring tightly

Removing gaps in an old wooden floor is a tricky one. Not all builders, when installing the finishing flooring, qualitatively prepare the floor in a private house made of wood.

Planks that have settled down over time dry up with different intensity and, accordingly, have some irregularities, therefore, all boards should be stitched before laying the substrate, and after that many gaps will "show their true size."

The gaps between the boards are sealed with a sealant or putty, only after that you can open the flooring with an antiseptic and varnish, this will help to make the floor in the apartment airtight.

As a rule, such gaps exist in wooden and frame houses, it is quite difficult to identify them, but this must be done in order to create a high-quality and warm flooring.

Raw overlap

Ground and basement floors often have cold floors due to moisture in the floors

The lack of a damp floor is found in rooms with a large basement and deep basements. Due to the fact that ventilation outlets are made in the foundations, moisture accumulates there, which can later be transferred to the floor.

To avoid this, it is necessary to organize waterproofing between the floor and the basement. To do this, it is enough to organize a layer of roofing material or membrane film, under which, for complete reliability, lay a layer of polypropylene with a thickness of 2-3 cm.

If the defect has already been found, then it is necessary to eliminate it and cut out the swollen segments from the screed, organize reinforcement and repair it with a special mixture.

Insufficient insulation

Floor insulation with special materials often solves the problem of cold

If the owner makes the repair or construction of the house on his own, then it is better to put an optional layer of insulation, but will not allow himself and his children to freeze, and will not make the floor icy.

If you hire a construction team that is ready to make repairs for a small fee, be prepared that unexpected "surprises" can await you everywhere, and insufficient insulation of the floor will also be a small drawback.

If the factor of insufficient insulation has already been discovered, do not despair, you can always find methods to eliminate it. For more information on the causes of cold floors, see this video:

For apartments, you can install an additional screed using expanded clay, which will partially solve the problem if the height of the ceilings allows. To solve the issue of insulation in private houses, there are several options:

The options for the used heaters and their characteristics can be seen from the table.

Also, this type of underfloor heating can be laid under a carpet or carpet, while the heating elements will not be damaged. For more information on the problem and its solution, see this video:

Asking the question: "When the floor is cold in the apartment, what to do with this?", Do not worry, there is a way out of any situation. Each owner should choose his own option from the listed reasons for the appearance of a "cold floor" and try to create thermal insulation using the proposed methods. You should not resort to the services of construction crews, it is better to do the work yourself or make sure that the work is done by trusted people.

How cold floors are insulated in a private house

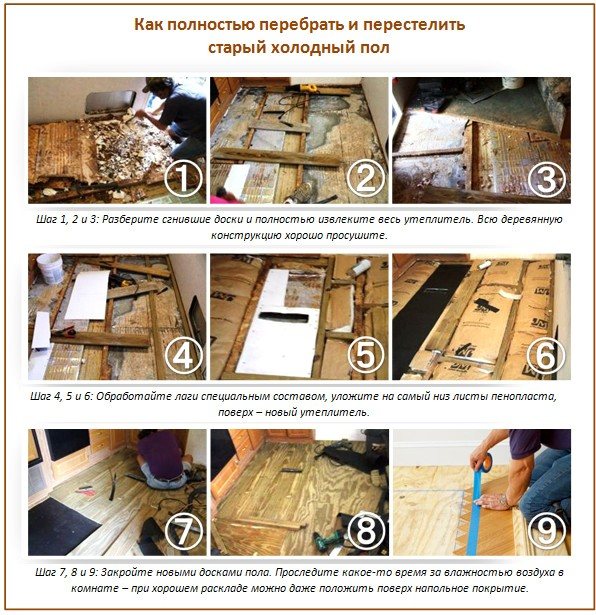

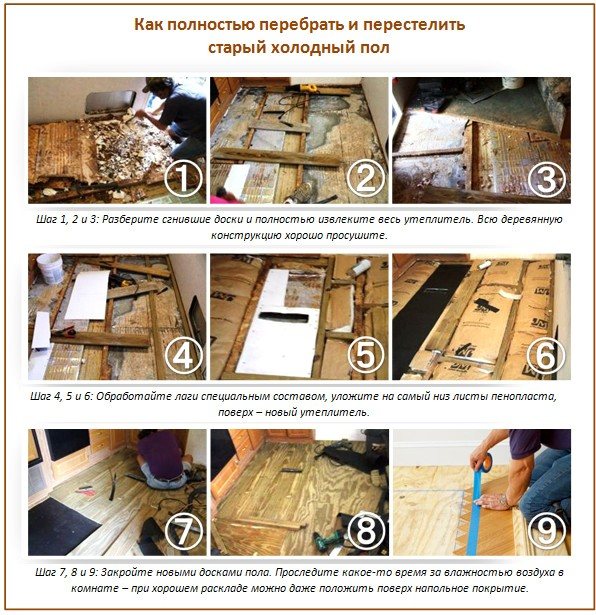

Thermal insulation of a wooden floor in an old house

Preliminary work

In an old house, you can insulate a cold floor without touching the walls and other parts of the building.

They are removing old boards. Examine them, throw away the rotten and rotten ones. Those that have not been destroyed are left and used again. Check the condition of the underground part

It is important to determine if the subfloor boards, joists and other wooden parts are well preserved. Rotten elements are removed to be replaced with new ones. While the floors are dismantled, check the ventilation vents, the condition of the subfloor and perform, if necessary, work in this part of the house.

Sometimes it is necessary to remove excess soil or, conversely, to add soil. After a thorough examination, new beams are installed or old, well-preserved logs are treated with a special protective compound. Then a sub-floor is laid from substandard or second-rate non-planed boards. They are also impregnated from rotting and damage by rodents. Further, they carry out warming measures.

Main works

It is better to insulate the cold floor in a wooden house with natural materials based on cotton wool. If the house is located near fields and in autumn and winter it is attacked by field mice and domestic rodents, glass wool should be preferred. We'll have to experience inconvenience during installation. But this will be a guarantee that the floors will last for a long time.

- On the rough flooring, a cage is mounted or slats are nailed in 40 cm increments.

- Next, lay the waterproofing - a polyethylene film. The canvases are overlapped, do not stretch, fasten with tape. The edges are bent upward with an approach to the walls by about 10 cm.

- Insulating material is placed in the spaces between the slats. You need to fix it. It fits well into the space allotted to it and takes on the required shape and size.

- Any vapor-tight is laid on top.

- Then plywood, chipboard, OSB or floorboards are laid.

- A topcoat is placed on top.

If the house is insulated with bulk material to insulate the cold floor, no waterproofing is done. Expanded clay and wood waste absorb excess moisture well and are not subject to destruction. The sawdust compresses over time and prevents heat from escaping.

Insulation of a cold, concrete floor

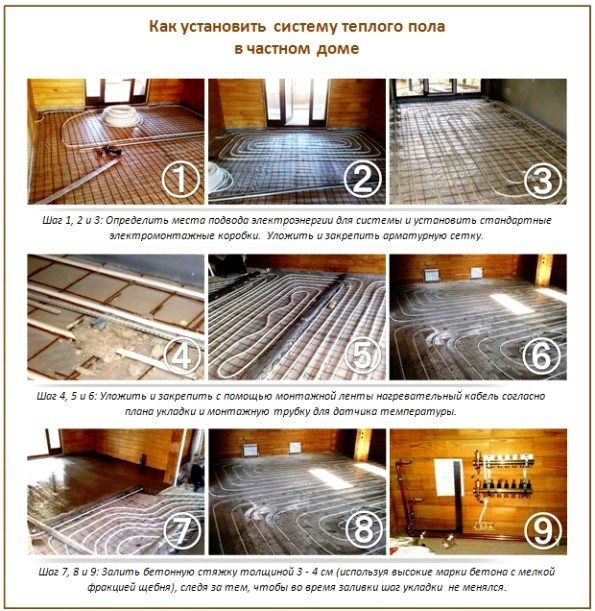

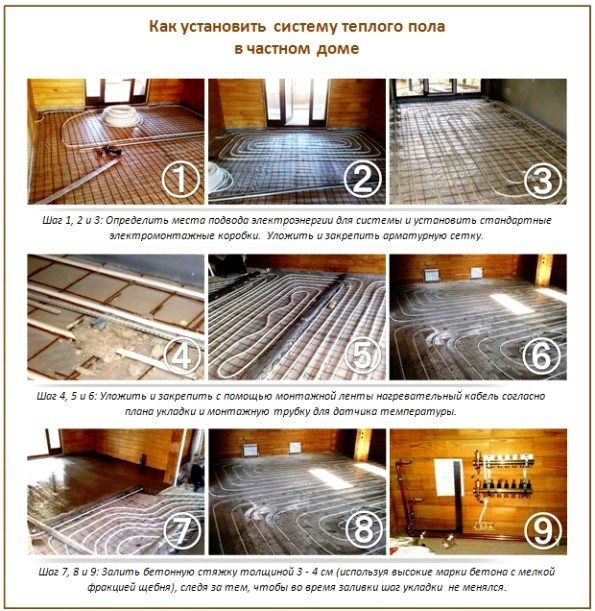

Underfloor heating system

A concrete slab on the floor of a house is a good foundation for a floor heating system.

After removing the old coating, the concrete is cleaned of dust and dirt, cracks and chips are covered, and the surface is leveled. For the installation of the water system, pipes are laid according to the scheme, they are connected to a heating boiler or a special device where water will be heated. Infrared mats are laid according to the manufacturer's instructions

It is important to consider the location of additional outlets in order to provide them with power. Water insulation is covered with plywood and other leveling sheets. The infrared system is covered with a thin layer of cement screed, waiting for it to solidify. Next is the finish line.

With such a device, the concrete floor in the house will always be warm and comfortable.

Cold floor insulation in the traditional way

The underfloor heating system may seem expensive to some homeowners. To save money, you can go along the path of insulation, as with a wooden base.

- On clean concrete, slats or boards are attached to the edge. It depends on the height you can pick up from the ceiling.

- Expanded clay is poured behind a layer of waterproofing (sawdust is not suitable) or mineral wool is placed.

- Everything is sewn up with plywood sheets or boards. The latter should be as tightly connected as possible and fixed with self-tapping screws. This flooring is impregnated with a special protective compound.

- Laminate, parquet, carpet and linoleum are laid on the plywood base. Boards are coated with varnish, mastic or decorative paint.

When building a new house, all insulation measures are carried out on laying the foundation and forcing the walls. here you should take into account the design features of the building. If the house will stand on screw piles or a columnar foundation, a thermal insulation system is required. Otherwise, there will always be a cold floor in the house.

All work on insulating the lower surface of the house can be done on your own. Knowing the basis of the technology and following the advice of experts, you can permanently get rid of the problem with cold floors. To keep the feet warmer, carpet is used for the topcoat or carpet runners are laid. This is especially true for bedrooms and children's rooms.

Reason # 1. Slots

The first and most common culprit for cold floors is crevices. So what if your dacha has exactly the same floors? Try this interesting option, which was especially popular back in the days of the USSR. Cheap and cheerful, as they say:

- Step 1. Cover the gaps between the boards with putty. Yes, you can use the most common store, paint it with regular floor paint and leave it like that - but it won't work. The fact is that a person presses on the floorboards with his weight, and they eventually bend - which is why both the putty and the paint fly off quickly enough. Therefore, we make the putty in our own way: knead finely sifted sawdust on PVA glue (for furniture). It is with this composition that fill the gaps, having previously lubricated the edges of the floor slats with the same PVA. Glue "Stolyar" is also suitable due to its water resistance.

- Step 2. Now, with an ax blade, cut off the protruding old blobs of paint on the floorboards and lightly sand the entire floor with medium-grained sandpaper.

- Step 3. In some problem areas, fix the boards with self-tapping screws. Just "drown" the caps themselves, and putty the holes with the same mixture as the slots.

- Step 4. Vacuum thoroughly the entire surface.

- Step 5. Now get a thin paper wallpaper with a wood texture (any other option is possible, of course).

- Step 6. Roll out the rolls in a convenient place and cover with a thin layer of parquet varnish (dilute it with a little solvent). This is necessary in order for the wallpaper to turn out to be more durable when wetted with PVA glue, also liquid diluted with water. In addition, otherwise the texture of the wallpaper may also wear off during smoothing. And stains from accidental touches will appear. By the way, it is the textured surface that we paint.

- Step 7. Now we cut the individual sheets of wallpaper - as wide as each individual board.

- Step 8. Apply glue to the boards and place the prepared sheets. If the gap is still noticeable, then slightly press the paper into it. But each strip must overlap the next. By the way, if the varnish bursts between the stripes, this will only add decorativeness to the entire coating, imitating a real plank floor.

- Step 9. Press the paper strips tightly and smooth them with a clothing brush to remove air bubbles.

- Step 10. Remove excess glue with a clean cloth.

- Step 11. Leave the new floor to dry for at least three days. After that we cover it with three layers of parquet varnish.

This is how it looks:

But what to do when the gaps are too large:

Such a floor will serve you surprisingly long enough, but you will forget about drafts through the cracks forever.

But if things are really bad, do this:

And in the complete absence of funds like this:

Insulation materials

The list of heat-insulating materials used in construction and repair technologies is quite large.

In terms of efficiency, ease of installation, the best heat insulators include:

- synthetic materials (polystyrene, polystyrene foam, polystyrene foam, teplex);

- modern wood fiber insulation;

- mineral wool;

- fiberglass;

- gypsum fiber sheets;

- liquid ceramic heat insulators.

In modern practice, bulk heat insulators are practically not used. The oldest of them, sawdust, is susceptible to decay, mold, and fire hazard.

The good thermal insulation properties of expanded clay are leveled by the large weight of the bulk material.

Fiber board materials, liquid ceramic heat insulators have shown themselves excellently, but they are expensive.

Fiberglass materials are quite heavy, can clump and cause allergies.

Quite expensive and mineral wool slabs. Thermal insulation properties are provided by low thermal conductivity of fibers from the melt of volcanic basalts, diabase, porphyrite.

For simple self-insulation, synthetic heat insulators are most acceptable, from a wide range of which you can make your own choice.

Ways to insulate the floor of the apartment

The choice of thermal insulation method depends on the structural features of the building and the installation features of the intended floor covering. Warming of floors in an apartment can be done as follows:

- Laying the heat-insulating layer from the outside. To do this, it is necessary to penetrate the underground, if possible. Unfortunately, it is not always possible to use this method for various reasons, although it is the outer insulation that is considered the most effective. The dew point is guaranteed to be outside the apartment;

- Installation of heat-insulating material along the logs, after removing the existing flooring;

- Screed on insulation.

Choosing the most appropriate method in a particular case, the landlord will eliminate the cause of heat leakage, and the cold floor in the apartment will no longer cause discomfort to its inhabitants.

A typical problem with floors on the first floors is a poor-quality base. Floor slabs have defects associated with the laying of utilities. Poorly sealed technological holes for pipes, cables can be a serious source of cold in an apartment. Before starting work on insulation, it is necessary to eliminate these shortcomings using general construction methods.

Correct floor design

We will divide all questions on this topic into two large groups - for houses with floors on wooden joists and for houses with floors on reinforced concrete floors.

There is also a separate group of houses with ground floor floors located above warm basements and a group of houses with floors on fill soil. The problem of cold floors does not concern this group of houses, because they have “heating” from below either from the basement or from the ground, which (if not allowed to freeze) has a stable temperature of +4 degrees Celsius.

For reinforced concrete floors, insulation is usually carried out with penoplex in several layers. All insulation should be done OUTSIDE, that is, from the outside with respect to the room. This also applies to the basement and floor. The blind area is also insulated with penoplex. Insulation sheets should fit snugly against the basement insulation sheets. In the case of an unheated basement, it is possible to insulate not the entire wall of the basement, which goes underground, but only its aboveground part. Naturally, in this case, the blind area of the house should also be insulated. The width of the insulation of the blind area depends on the depth of freezing of the soil in winter for a given region. The width of the insulation of the blind area should be greater than the depth of soil freezing.

Between the wooden logs, sheets of insulation are laid or insulation is filled / blown out, which does not go in the sheets. For insulation of floors on wooden logs, you can use basalt wool in sheets and bulk, ecowool, polyurethane foam.

Reason number 3. Lack of insulation

When you do everything in the house with your own hands - would it ever occur to you to put half as much insulation under the floor than the instructions are for? Hardly, you will agree. After all, you will freeze afterwards. But it’s easy for a hired construction team. The floor cake looks decent, everything is done, at first glance, professionally, and the lack of building materials is not so easy to calculate. Especially if you yourself do not understand much about this. But the same remainder can be added to the second client, and everything will also look decent. But the foreman was paid for two whole sets!

Bottom line: cold floor. What to do? It is easy to check the insulation layer: find on the Internet what layer should be in the material that you have, and check with a simple metal ruler. A clear flaw? The floor will have to be completely opened.

So, it is also possible to completely solve the problem thanks to - it is a light and harmless material that serves as an excellent heat and vapor barrier. Or more complex, but no less effective options for complex cases - we have provided step-by-step instructions below.

When it comes to an apartment, there are many options. But the simplest and cheapest option is to make the floors in a private house much warmer:

- Step 1. At the lowest point of the underground -, 10-20 cm.

- Step 2. Put 10 cm of polystyrene on top of it, and very tightly. This insulation should completely cut off the cold from the ground.

- Step 3. On the foam - a layer of fine expanded clay, up to 70 cm.

- Step 4. Now - an air gap with air vents in the foundation. We close them completely for the winter.

- Step 5. Next, we are already installing wood floors. Such a floor should lie on the grooves of the log, which are closed with a rubber tape (if you have such walls). The purpose of the tape is to separate the floors from the wall so that the sound of walking on the floors is not transmitted to the walls. Those. elementary insulation.

- Step 6. Next, lay out the rubber sheets along which the waterproofing is laid.

- Step 7. And, finally, if desired - a layer of screed 7 cm thick with underfloor heating. Then - the floor covering.

If you just have a wooden floor with logs, and under it is one damp earth, do this:

- Step 1. Carefully remove the cover.

- Step 2. We process the logs with a special compound (you can even just use used oil).

- Step 3. We attach a corner to the lugs to stretch the cord. We pull on the cord - the foam will hold on it, and the corner can be removed. Attach the cord to the lags.

- Step 4. Install 50mm Styrofoam sheets. We seal the cracks between it and the tree with foam.

- Step 5. On top of the foam we lay Penofol, thickness 3 mm. We install the floor boards in their place.

- Step 6. Now we fix the foam from the underground. So, we take the nylon roofs from the cans, and press the foam with self-tapping screws and a screwdriver.

This is the simplest and most unpretentious method. You can also install underfloor heating:

Common Causes of Floor Cooling and Remedies

The temperature of the floors is influenced by 3 components: the object under the floor (base or room), thermal insulation and floor covering, its material and condition, and temperature is also directly related to the level of humidity. Sometimes the cause may lie in one of these factors, sometimes in a combination of them.

Cold pulls from the base

The floors are located too close to a cold base - soil or concrete, and there is no insulation layer between them or its thickness is insufficient. The problem is especially acute in winter, when the ground or the non-insulated foundation under the floor on the first floor freezes. You can solve the problem by lifting the floors, thoroughly insulating the space between the floor and the base, as well as the foundation or basement.

It's damp under the floor

Usually such a problem arises in the spring in private houses, when the underground floor frozen in winter begins to thaw, condensation accumulates.

The bottom should be protected from moisture by a layer of waterproofing under the insulation.Sometimes it is necessary to close the side ventilation holes - air vents - in the basement so that dampness does not penetrate there from the street, and instead install a ventilation grill above the basement, in the floor. If the floors are saturated with moisture, wait for them to dry or use equipment such as a heat gun to speed up the process. But the coating may deform as a result.

Lack or insufficient floor insulation

We need better thermal insulation, made in accordance with the calculations, it is also necessary to take care of the waterproofing and vapor barrier of the insulation, and if there are mice under the floor, think over a way to deal with them and close up the moves.

There are cracks in the floor

If the floors are planks, and the boards do not fit tightly to each other, through the cracks it will pull cold from the bottom and heat away from the house (apartment), dampness also penetrates through them. The slots can be repaired with putty, and so that new ones do not form, the loosened boards can be fixed with self-tapping screws. It is even better to supplement these operations by laying a dry screed made of plywood and other panel or sheet materials.

Cold floor covering

The problem can be solved with the help of a floor heating system, but you need to choose it correctly for specific conditions. High-quality thermal insulation must be performed under the warm floor, otherwise it will not be the room that will be heated, but the subfloor.

Working with finishing coatings

The problem is with the laminate: the outer decorative coating conducts heat well. A cheap way to solve the problem is to use a technical plug under the base coat. Expensive and more practical is the underfloor heating system. But it is appropriate only in the absence of cracks and dampness.

If the covering was laid using the locking method, there are no problems. Remove, install "warm floor", put the laminate back. If you glued it, forget it. It is better to take care of the heating system as a whole - install infrared heaters in the house - they heat not the air, but objects.

Absorption of infrared radiation is another reason for possible heat loss. Your flooring has the ability to absorb heat and heat up the subfloor. Place the foil material facing up under the laminate. The difference is enormous!

What to do if the floor in a private house is cold

- The only correct solution would be floor insulation.

- If the house is under construction, then you need to take care of its thermal insulation in advance. When people already live in the house, then the solution will be to build up the floor or disassemble. It all depends on your desires and financial investments.

- First of all, check the ventilation hole in the basement of the house. It should be tightly closed during the winter cold season.

- Carefully investigate the absence of gaps between the first crown and the basement of the house.

- Take a closer look at the ceiling. According to experts, the main reason for drafts and a cold floor in the house is a poorly insulated ceiling. The ceiling is insulated - the problem is solved.

- Install the "Warm floor" system. But with improper insulation of the outer space, it will bring little benefit.

Floor and ceiling

The cold floor in the house is a cause for excitement. There are various reasons for the problem, as well as methods for solving it. Let's consider the most common situations.

The leading position is occupied by gaps. They are present both in private country houses and in apartments rebuilt during the Soviet era. It is not necessary to rip off the wooden floor and fill everything with concrete. Try to patch up the holes.

First of all, cover the cracks with a special putty. A store store will not work, since under the pressure of the weight of the boards, the boards bend, and the putty falls off along with the paint. We cook ourselves - knead small sawdust with PVA furniture glue. The edges of the floorboards are coated in advance with the same glue.

Remove a layer of old paint from the floor (we recommend using an ax blade) and sand the entire area with medium sandpaper.

In places where the boards are most susceptible to deformation, strengthen them with nails.Sink the caps, putty with homemade mixture and sand.

Vacuum the floor

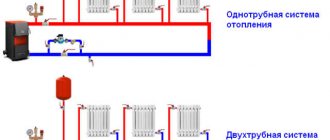

Warm floors from hot water

Installation of water heating is a step-by-step observance of the entire cycle from the beginning to the start-up of the system. The length of the pipe is determined by calculation, depending on the area of the room.

Advantage

- Provides uniform heating of the entire floor.

- The pipes are hidden and do not change the aesthetic perception of the interior.

- The closed cycle of hot water from central heating does not affect the total cost of utilities.

- Correctly selected materials will not rust, which guarantees the system a long service life without leaks.

Equipment

- Metal-polymer or polymer pipes (preferably corrugated, bendable).

- Thermal insulation.

- Fasteners.

- A manifold with a fitting for connecting to a battery.

- Damping tape, mounted on the wall along the perimeter, in the aisles of the height of the structure.

- Reinforcing mesh.

- Aluminum plates.

Folk method of floor restoration

Take paper wallpaper (wood pattern is recommended) and varnish on the front side with parquet varnish, slightly diluted with solvent. This will give the canvas strength and will not deform the texture when smoothing.

Cut the wallpaper - each board should have its own sheet, and the corresponding width.

Dilute PVA glue with water to a liquid state, apply to boards and lay sheets. Press the edges of the paper into the palpable slots. If the varnish bursts, it's okay. You will get a kind of imitation of a natural wood covering.

Next, smooth out air bubbles, remove excess glue with a clean cloth, dry for 3 days. After - fill in 3 layers of parquet lacquer.

A simpler option suitable for a residential apartment:

1. Remove the skirting boards and the old covering.

2. Cover the floor with plywood.

3. Fill the cracks with polyurethane foam around the perimeter.

4. Put on a new covering, especially carefully hiding the foam from the sun's rays.

Types of heaters

Expanded polystyrene

Polystyrene sheets with grooves for insulation and floor leveling

Expanded polystyrene, better known as polystyrene or its modified counterpart, penoplex has excellent thermal insulation properties, is lightweight and easy to use. There is also extruded polystyrene foam. Its difference from the usual one is in water resistance. If ordinary expanded polystyrene can absorb a certain amount of liquid and deform because of this during temperature changes, then its more technological form is almost completely waterproof. The only drawback of expanded polystyrene is its flammability.

Expanded clay

An example of different types of expanded clay used for insulation

This bulk material is attractively priced and versatile. Can be used with dry floor screed or mixed with cement mortar. Also, with its help, you can arrange a floating screed with your own hands.

Polystyrene concrete

Unlike expanded clay, polystyrene concrete requires a much smaller layer to create acceptable insulating properties. Almost anything can be laid on it, including tiles. In addition, it has excellent sound insulation properties. You will learn more about this material from the video.

Mineral wool

Mineral wool, as well as glass wool, are some of the most popular insulation materials, which are made in the form of tiles or rolls. The advantages include thermal insulation properties, reasonable price and vapor absorption. The disadvantages are the composition hazardous to health. When installing with your own hands, you should use respirators and avoid contact with exposed parts of the body. Therefore, mineral wool and glass wool need to be carefully insulated to prevent dust from entering the premises.

Bung

Cork is used as a backing for laminate and as insulation material

Cork is perhaps the most expensive material on our list.It is environmentally friendly, durable and moisture resistant. It can be used even for fine finishing, because in addition to its insulating properties, it looks beautiful as a topcoat. Among the disadvantages can be noted the instability to cuts and other mechanical damage.

Ecowool

It is made on the basis of cellulose, which means it is environmentally friendly and not hazardous to health. It has high heat and sound insulation properties, but does not tolerate moisture. Therefore, it is used in areas where there is no risk of contact with moisture. For more information on the advantages and disadvantages of ecowool, see the video

Penoizol

This is liquid polystyrene foam, all the advantages of which we talked about above. The advantageous difference between the liquid form of such a material is in the ability to penetrate into the most inconvenient places.

Warm floor

Installation of electric underfloor heating

The option of installing a warm floor is becoming more and more popular. Only its cost repels. There are several variations:

- Water;

- Electric;

- Infrared.

Hot water floor, heats with the help of communications with hot water under the subfloor. An electric underfloor heating is also installed and heats by converting electricity into heat. Infrared is the most modern, simplest option and can be laid with your own hands without the involvement of specialists. Thin elements of the warm floor are placed under the finishing flooring. Only this type of floor can be done by hand, without special skills.

How will we insulate

The choice of a particular type of insulation is largely determined by the required degree of insulation, as well as by how high the walls are - some inexpensive types of insulators are thick enough and will take away part of the space during installation. At the same time, the choice of insulating materials is not as great as it might seem. You will have to choose the best way to insulate the floor in the apartment from the following options:

- Loose mixtures. Among them there is fine expanded clay, and a variety of modern heat insulators, and even sawdust. The latter option is exotic, but even it is sometimes used.

- Cotton wool insulation - mineral or stone wool. Some suggest using glass wool, but this is one of the worst advice - it is difficult to isolate it from the surrounding space, otherwise extremely harmful tiny particles of glass wool will get into the air.

- Styrofoam or expanded polystyrene is a good option, besides, it is also very cheap. It is the affordability that makes it one of the leaders in popularity.

- Roll insulating coatings based on foamed polyethylene. It is inexpensive, but in terms of characteristics it can be inferior to other materials. It is used when it is necessary to save space and there is no need for very serious insulation.

It is impossible to single out the best of the presented types of insulation. For each case, you need to choose the most suitable type of insulation. Some of the presented coatings will only allow you to create a heat-saving layer, while others will make it possible to simultaneously insulate and level the floor in the apartment. Based on these points, it is worth considering all types separately.

As the coating is the warmest

The cork is the warmest. This is an expensive elite material that can be installed in any room, except in places where there is high humidity. It is absolutely impossible to lay a cork on a bare concrete floor. This covering can be made in the form of slabs or rolls. In order to make the laminate or linoleum flooring warmer, a cork is also sometimes placed under them. It provides excellent thermal insulation and protects against extraneous noise.

The cork does not react to temperature changes and is capable of withstanding serious loads. It is not static and does not accumulate dust and hair on itself. The carpet looks very much like a carpet. It can be quite tough and soft.This flooring is convenient because it has a low risk of injury, so it is often installed in children's rooms. Carpets can be made from both natural and artificial materials. This is a warm covering that reliably protects your feet from the cold floor.

Reason # 6. Absorption of infrared rays

Pay attention to a physical phenomenon that can cause cold floors in your home, such as infrared radiation. Sometimes it happens that the floors absorb heat so much that in the end you, without knowing it, are heating the underground. This is especially true for such a decorative coating as laminate, as it has a high thermal conductivity. Therefore, if everything is insulated and you do not observe any cracks, put sheets of foil material under the decorative coating. Trust that you will immediately notice a colossal difference.

Base primer

Polyurethane

The second name of the composition is an epoxy primer, which has the property of deeply penetrating concrete. Apply the component to the screed with a roller. Work with a brush around the perimeter of the base. Spaces are not allowed. This type of primer is effective for adhesion to self-leveling floors, prevents the formation of fungus and moisture penetration.

Concrete contact

This is a composition of acrylic with quartz sand. Apply with a roller and brush. After priming, a rough surface is formed on the base, ensuring tight contact with the subsequent layer. Acrylic in the composition makes the film resistant, preventing moisture from entering the concrete. After 4 hours, from the moment of applying the composition, proceed to the next stage of insulation.

Cotton wool

This type of insulator is also popular. A very effective heat-saving structure can be created using stone or mineral wool. The disadvantage will be similar to the previous type of insulation - thickness. However, keeping warm is often more important than having extra free inches above your head. The laying of wadded insulation is carried out inside the ceiling - between the bearing logs. If you have concrete floors, you will have to assemble a kind of crate of five-centimeter bars. Cotton wool is laid between them.

Stages of work on installing thermal insulation

The house is set directly on the ground.

- make a bed of sand or crushed stone under the ceiling;

- build a wooden floor as a rough draft;

- a layer of waterproofing is laid;

- put a heat insulator between the logs (parallel wooden planks).

- a vapor barrier must be installed on top.

- finishing floor with the obligatory leaving of a gap for ventilation between it and the heat insulator.

The cold floor is above the basement. In this case, it is necessary to increase the floor by a few centimeters.

- A waterproofer is placed on the cleaned sub-floor.

- Lags are laid on top.

- Insulation is laid between them.

- Then the underlay and the finishing floor appear.

Little tricks:

- if there is a basement under the cold floor, then before starting the insulation procedure, take care of the thermal insulation of the basement walls;

- do not forget about ventilation when installing insulation;

- do not save money on the purchase of a vapor barrier and a waterproofer:

- do not forget to treat wooden boards with an antiseptic.

Polystyrene and Styrofoam

The principle of stacking and non-delivery will be similar for this insulation. To insulate the floor in an apartment with expanded polystyrene, you will need to assemble a structure of wooden bars, between which a layer of foam will be laid. The distance between the bars is selected based on the dimensions of the polystyrene plates used. They must fit snugly between the frame elements. When all watered are laid, the existing gaps or cracks are sealed with polyurethane foam. The finishing floor is laid on top.

Why do private homes have cold floors?

There are several reasons why the floors are cold in a wooden house.

- The structure of a wooden house is prone to changes: the wood deforms, the structure settles. If you rush and lay the floors until they are completely shrink, they will warp and be cold.

- Natural wood, from which floorboards are made, eventually deteriorates and dries up. Cracks are formed. Cold air enters through them, which cools the floors. If the house is old, then it is understandable why the floors are cold.

- In a new house it will be cold on the floor if mistakes are made during its installation.

- If the floor covering is laid on a concrete base, which cools down a lot in cold weather, then it will be uncomfortable to walk on it.

To properly insulate floors, you need to know the reasons for their cooling.

Reason number 7. Tactile sensations

And finally, one of the most unexpected reasons why the floor can be cold is purely tactile sensations. Simple physics is at work here: in fact, cold as a physical phenomenon does not exist - it is just a lack of heat. And different materials do not have the same ability to absorb this heat from other sources. And the absorption takes place - for the sake of updating the same balance. And those objects and coatings seem warmer, which take heat away from you more slowly.

So, for example, if you get up from a familiar place, you can only feel with your palm how your body has heated one part of the sofa or bench, and the second has remained cold. Moreover, the heated place will be about the same temperature as your skin. The same applies to the floors - as soon as your foot touches them, a rapid heat exchange takes place. And its intensity depends on the thermal conductivity of the flooring material: the higher, the colder the floor will seem, if, however, you do not heat it from below.

It turns out that the approximate room temperature is about 18-20 ° C, and below it is about 15-17 ° C. This is the temperature the floor will have. And now you see what's the matter: 36.6 ° - 17 °? That is why we can experience quite unpleasant sensations from walking barefoot, although it seems that it is not cold in the house itself. And from this you can really get sick - after all, heat is "downloaded" from us, and the body needs it.

So what should you do? And is it then necessary to install a "warm floor"? Not at all. If you definitely do not have cracks, and the floors do not freeze due to improperly equipped underground and the matter is definitely not in the organization of heating, then work with the floor covering itself. So, ceramic tiles have the highest thermal conductivity - they most quickly "rob" us of heat, especially in the area of the bathroom. And do not walk endlessly in rubber slippers, and the rugs in such a room can get damp. Not to mention the fact that no one will rip off the tiles again - otherwise, there is no other way to put a warm floor system under it.

Here, see how such a problem is solved overseas with humor and creativity:

Modern PVC tiles are also a good option: they have the same low thermal conductivity as cork. You can even, for the sake of experiment, bring it to the balcony, leaving it there all winter night. Pick it up by morning - it will not seem cold even then.

Do not tolerate the cold - the time and effort spent is worth it to welcome every morning with comfort!

A wooden house is considered environmentally friendly and warm. But if it is unexpectedly cold in it, or the heating costs are relatively high, then there are structural violations, increased heat leakage. Insulating a house made of wood is usually a little cheaper because the walls themselves have an increased resistance to heat transfer compared to cold materials.

How thermal insulation measures are done in this case, what is necessary to create comfort and warmth, - a few practical recommendations ...

Wooden walls are not warm enough

Wooden walls with a thickness of only 20 cm in terms of thermal insulation properties are comparable to foam plastic (foamed polystyrene foam) with a thickness of only 5 cm.

The heat transfer resistance of such a design is less than the standard required for most of our regions. And for cold climates - much less!

The SNiP requirements for a temperate climate would almost be achieved if the walls were made of 40 cm thick timber.Then it is definitely not necessary to additionally insulate them.

But in a house with such walls, it can still be cold if there are obvious heat leaks through other structures. Walls made of timber (logs) with a thickness of 20 cm, it is advisable to re-insulate, but in the last place, after the maximum heat saving has been achieved with other structures.

Why is the house uncomfortable - low heat capacity

Another issue is that the temperature in the house changes rapidly, "jumps" after external changes and when the doors are opened, so the feeling of comfort is lost.

The reason for the phenomenon is that wood has a low heat capacity. In the old days, in the middle of the house there was a massive stove, which was a heat accumulator and a stabilizer for the internal microclimate.

Inside a modern wooden house there must be a "pile of stone". You should not trust smart ventilation and air conditioning systems to regulate the microclimate. Since you still can't get rid of the feeling of discomfort and toyiness of the home, and the costs for this are by no means small.

The role of a temperature stabilizer inside the house can be played by piers made specially from bricks, a concrete screed - a heated floor, fireplaces, or simply massive (tons of stone), heat-intensive interior elements.

It is not only the buffer tank that stabilizes the temperature of the home. It is better to take care of the internal heat capacity and create massive structures inside.

It is necessary to find the places of energy leaks

To resolve the issue of cold, you need to carefully consider the state of thermal protection in the complex. It is a good idea to look at a house through a thermal imager during cold weather when it is heated. But even without this device, according to the state of the structures, the thickness of the material and its appearance, it is quite possible to figure out how the heat leaves.

For wooden walls, the issue of the presence of cracks everywhere, and the high air permeability of the walls is important. The phenomenon can be dealt with by different methods, both by sealing gaps and by using continuous membranes or finishes .... How best to insulate such fences of a home - you can find out on this resource.

Heat leakage through windows and doors, their insulation

If the frames are old, then most likely they will be the main culprit in the cold in a wooden house. A through slot is a very serious heat leak. First of all, you need to eliminate the draft.

The solution to the problem of insulating windows and doors is simple - the installation of modern systems. Moreover, it is necessary to install double-glazed windows with sprayed glass and double doors. But this is expensive ...

How old windows and doors are usually repaired

You can repair old frames and doors with your own hands. The procedure is as follows.

We insulate the ceiling

In an ordinary house, the ceiling plays a very important role in the thermal insulation of the entire building. After all, warm air, as you know, from heating devices rises straight up and heats primarily the ceiling. If it is not insulated, then the room will simply be cold, with any insulation of other structures.

Ceiling (usually wood flooring) - needs to be insulated from the attic side. Polyfoam is not recommended to be used due to the fact that it is extremely dangerous in case of fire if it is inside the building.

Most often, the ceiling is insulated with mineral wool - a layer of 15 - 30 cm, depending on the climate. But you can also use natural cheap materials mixed with lime to make them biostable.

Apply 30 - 50 cm thick layer of hay, straw, leaves, or their combination….

It is important that the corners and the edges of the attic are insulated with high quality.

Vapor barrier and other design features

When insulating the ceiling, it must be borne in mind that a large amount of steam tends to leave the house through it, which poses a threat to heaters, since condensation will occur right inside them, and water may accumulate.

Therefore, the overlap is closed with a continuous vapor barrier (polyethylene, polypropylene) membrane. It can fit between the lag with a twist to a height of 10 cm.

A layer of insulation is laid on top of the membrane. If you use mineral wool, then it must be covered with a vapor-permeable (diffuse) membrane from above so that the fibers do not scatter.

In general, if there is a desire to make the house warm, then the attic floor needs to be worked on thoroughly, and the thickest layer of insulation should be applied here - the heat transfer resistance of the ceiling should be almost 2 times more than that of the walls.

The floors are made warm

Insulating wooden floors is not difficult. You just need to make a decision - whether to build the second floor above the first or to tear off the floors and lay insulation on the ground or between the logs.

In general, the second option is more acceptable for economic reasons, and a significant decrease in the height of the room when raising the floors is not always suitable.

So, the boardwalk is removed so that it is easy to put each board in its place.

Soil is a source of moisture, and the first thing to install is a vapor barrier. The same materials are used as for the attic, but here it is safer to put two layers of roofing material with a twist on the walls above the floor level. If the underground is not at all high, then it makes sense to fill the insulation directly on the ground (on the vapor barrier layer). Can be used with a layer of 25 cm of straw-deciduous options, with a layer of 35 cm - expanded clay or coal slag sifted out from the lumber.

Placement of insulation between the lag

If the underground is high, then it is better to place the insulation between the logs. A 15 cm layer of glass wool is suitable, without phenolic binders or ecowool - cellulose wool. First, beams are screwed to the logs from the bottom (side), flooring is made of thin boards, plywood, slate ... on which the vapor barrier is laid.

A layer of mineral wool (ecowool, etc.) is separated from the inner space of the house by a vapor barrier. This prevents steam from escaping into the insulation, and also protects the room from harm.

Moisture from the insulation must be carried out by the air when the underground is ventilated.

The humidity in the underground should not be increased.

When the temperature reaches below zero under the lags, the thickness of the insulation should be increased by a third.

Mineral wool with a density of up to 80 kg / cubic meter can be blown through with an air stream, therefore it is covered with a superdiffusion membrane.

Walls made of logs and beams are sometimes insulated ...

After insulating windows, doors, ceilings and floors, as a rule, the issue with the cold is resolved radically for the better. But sometimes wooden walls fail.

The blame for everything is the gaps between the logs or beams. As in the old days, they need to be caulked. Previously, moss was used for this, now - hemp, jute, they need to be stuffed with a sharp tool from the outside and from the inside into the cracks.

For the best insulation and maximum savings on energy resources, it is possible to bring the thermal insulation of wooden walls to the standard value - 3.3 m2C / W for a moderate climate in the middle zone, you can additionally insulate all walls from the outside with a layer of mineral wool of 5 cm or more.

It is impossible to insulate wooden walls with polystyrene, since its resistance to the movement of steam is much higher than that of a tree. The basic principle of wall insulation will be violated - a vapor-permeable layer from the outside. That threatens to get wet, rotting wood.

Cold floor in the apartment what to do

Insulation of the concrete floor is very important for creating comfort and warmth in the house, especially if the apartment is located on the ground floor.

But wooden floors also sometimes require insulation.

For example, in a private house, no matter how well the coating is made, it does not give a full guarantee of heat preservation, which means that it will not be possible to save on heating.

Why do you need to insulate the floor?

The systemic heat exchange of a house or apartment largely depends on the floors, since they are the places of great heat loss.

Concrete is durable and has excellent performance, popular for flooring, but it has one serious drawback - the material is very cold. If it is located in a residential area, then high-quality thermal insulation is required, otherwise any heating will not be effective.

A cold floor means uncomfortable conditions in the room, significant energy overruns for heating.

In addition, in the absence of insulation and waterproofing of the floor in an apartment on the ground floor, located, as a rule, above an unheated basement, dampness can form, and as a result, mold on the walls.

All this can be avoided with a high-quality insulation structure.

The job of insulating the floor is not impossible. If you have the necessary materials and tools, any owner can handle it independently.

What kind of insulation is better to choose?

There are several types of insulation, produced in the form of blocks, bulk materials, rolls, and even in liquid form. Each of them is quite suitable for insulating the cold floor of the first floor.

Mats and slabs

Heaters of this type have low thermal conductivity and low weight, they are the best suited for insulating the concrete floor of the first floor.

They can be used in conjunction with thin roll materials, which increases the overall thermal insulation.

Heaters in the form of mats and slabs are made of foam, mineral wool, basalt fiber, based on expanded polystyrene and other composite materials.

Since olden times, mats made of plant fibers, for example, from straw, which is an excellent environmentally friendly insulation, have been used to insulate floors in private houses. The only negative is that organic matter undergoes decomposition over time.

Loose heaters

Bulk materials include expanded clay as floor insulation, sawdust, foam chips, slag and others.

They are used to insulate floors in ground floor apartments, as well as in private houses.

The advantage of bulk insulation is that they completely fill the space between the sheathing bars.

This material is suitable both for placement on the open ground under the floor in a private house, and in apartments with an unheated basement below.

Roll materials

Foamed polystyrene, mineral wool, cork or cork-based composite mats, multilayer foil insulation, etc. are produced in the form of rolls.