Foil insulation

NON-FLAMMABLE BASALT FOILED HEAT INSULATING MATERIAL BIM-6F, BIM-8F, BIM-12F NEW !!!

Basalt Needle Mat is a new product. Basalt mats show better thermal and sound insulation properties than glass mats, an extended range of temperatures for use and easy processing into a final product. Moreover, basalt mats are environmentally friendly and easy to recycle. Due to all these properties, basalt needle-punched mats can also be used in filtration applications.

Basalt needle-punched mat (hereinafter BIM) laminated with foil on one side. does not have a binder, the formation of the material occurs due to repeated piercing with needles. Whereas traditional thermal insulation is formed by resin, which, upon gradual evaporation, releases toxic gases such as phenol, formaldehyde and many others.

The basis of BIM is basalt fiber with a diameter of 10 microns to 17 microns, in other materials basalt and glass superfine fibers with a diameter of 3-4 microns are used, which are carcinogenic materials.

BIM does not shrink during operation and installation, and therefore there are no gaps between the heat-insulating material and the insulated surface. Easy to cut, elastic and, therefore, technologically advanced when performing installation work.

Application temperature from -200 C to + 700 C. High resistance to aggressive environments.

Application area:

They are used in various industries, heat power engineering, aircraft construction, agriculture, housing construction and gas station equipment. They are non-flammable, non-toxic and environmentally friendly, therefore they are used in healthcare and educational institutions.

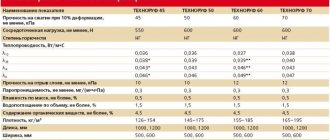

Material specifications.

Characteristic

| unit of measurement | BIM-6F | BIM-8F | BIM-12F | |

| Density | kg / cubic meter | 100 | 120 | 140 |

| Length x width | mm. | 1200x10000 | 1200x10000 | 1200x5000 |

| Thickness | mm | 6 | 8 | 12 |

| Thermal conductivity | W / (m C) | 0,038 | 0,038 | 0,038 |

| Humidity | % no more | 0,1 | 0,1 | 0,1 |

| Content of substances removed during ignition | % no more | 3 | 3 | 3 |

| Flammability | power | NG | NG | NG |

| Roll length linear meter / m2 | 30 / 25 | 20 / 24 | 10 / 12 | |

| Call us, we have real prices and big discounts !!!! | ||||

BASALT PUNCHING MAT-BEAM NEW !!!

Basalt Needle Mat is a new product. Basalt mats show better thermal and sound insulation properties than glass mats, an extended range of temperatures for use and easy processing into a final product. Moreover, basalt mats are environmentally friendly and easy to recycle. Due to all these properties, basalt needle-punched mats can also be used in filtration applications.

Basalt needle-punched mat (hereinafter BIM) does not have a binder, the formation of the material occurs due to repeated piercing with needles. Whereas traditional thermal insulation is formed by resin, which, upon gradual evaporation, releases toxic gases such as phenol, formaldehyde and many others.

The basis of BIM is basalt fiber with a diameter of 10 microns to 17 microns, in other materials basalt and glass superfine fibers with a diameter of 3-4 microns are used, which are carcinogenic materials.

BIM does not shrink during operation and installation, and therefore there are no gaps between the heat-insulating material and the insulated surface. Easy to cut, elastic and, therefore, technologically advanced when performing installation work.

Application temperature from -200 C to + 700 C.High resistance to aggressive environments.

Application area:

They are used in various industries, heat power engineering, aircraft construction, agriculture, housing construction and gas station equipment. They are non-flammable, non-toxic and environmentally friendly, therefore they are used in healthcare and educational institutions.

Material specifications.

| Characteristic | unit of measurement | BIM-6 | BIM-8 | BIM-12 |

| Density | kg / cubic meter | 100 | 120 | 140 |

| Length x width | mm. | 1200x25000 | 1200x20000 | 1200x10000 |

| Thickness | mm | 6 | 8 | 12 |

| Thermal conductivity | W / (m C) | 0,038 | 0,038 | 0,038 |

| Humidity | % no more | 0,1 | 0,1 | 0,1 |

| Content of substances removed during ignition | % no more | 3 | 3 | 3 |

| Flammability | power | NG | NG | NG |

| Roll length linear meter / m2 | 30 / 25 | 20 / 24 | 10 / 12 | |

Tel./fax, 200-43-77

E-MAIL:

Advantages that only foil insulation has!

Due to the combined structure of the material, consisting of a layer of thermal insulation and polished aluminum foil, a number of unsurpassed performance characteristics are provided, which put this type of insulator one step ahead of traditional products.

- Aluminium foil - an excellent heat reflector capable of reflecting 95 to 97% of heat. Such a heat insulator has a low coefficient of thermal conductivity, therefore it perfectly retains heat or cold in the case of insulation of refrigeration equipment.

- Lined heat and sound insulation is a reliable protector from wind, dampness and other vagaries of the weather. It does not dry out when heated by the sun and does not change its characteristics at negative temperatures.

- Foil is a hydrophobic material, repelling moisture, therefore protects the thermal insulation layer from getting wet. As a result, the insulator retains its heat-insulating properties, and metal structures are protected from corrosion.

- Acoustic performance foil-clad insulation allows you to damp up to 80% of shock, airborne noise and vibrations, which is especially important for achieving working comfort in production workshops of enterprises.

- The material is sold in various shapes and sizes... You can buy products in standard plates and mats, foil roll insulation or insulation in the form of wound cylinders Rockwool 150. This choice allows you to find the optimal product for insulating surfaces of the most complex geometry.

- Foil insulation thickness on the basis of basalt varies within 25-50 mm and is selected depending on the requirements of the project, the type of insulated structure and the climatic characteristics of the region.

- Made from natural raw materials without toxic additives, inclusions, mineral wool insulation with foil refers to environmentally friendly materials, therefore it is 100% safe for the human body and nature.

- Such insulation does not rot, does not rust, does not shrink during operation. Insulation with foil for the walls of a bath or sauna, underfloor heating, pipes and chimney will serve for at least 50 years with full preservation of its properties.

Important! Foil insulation will cost you several times less than buying heat insulation and vapor barrier film separately. And if we add here the cost of installation and the effectiveness of insulation, the benefits of using laminated insulation are obvious.

Areas of use

It is used for internal and external heat, steam, sound insulation of walls, floors, ceilings in residential, administrative and industrial premises, hot and cold water supply systems, air ducts, ventilation and air conditioning systems, freezing and refrigerating chambers, tanks and reservoirs. The presence of reflective foil gives the maximum effect when insulating building structures and other objects near heat sources (insulation of baths, saunas, roofs of houses, heating systems and pipelines).Recommended for heat and vapor insulation of roofs, ventilation, exhaust and air conditioning ducts, metal structures. For thermal insulation of the roof, it is recommended to use insulation foil on both sides, then in the summer it will protect the under-roof space from overheating due to the reflection of external thermal radiation, due to the low thermal conductivity and high reflective characteristics of the foil, it reduces heat loss by 25% -30%, protects the walls from freezing blowing and dampness. The use of foil thermal insulation can significantly save on space heating.

Basalt insulation brands for chimney insulation

Various manufacturers, the consumer are offered more than several dozen names of basalt heaters. Some are made abroad, others at domestic enterprises.

Judging by customer reviews, the products of the following companies are popular:

- Basalt wool Rockwool is produced at the enterprises of the company of the same name, located in Denmark. According to its characteristics: hydrophobicity, sound and thermal insulation, as well as mechanical strength, Rockwool significantly outstrips analogues of other manufacturers. Basalt wool Rockwool is used by manufacturing companies for insulation of finished ceramic chimneys Schiedel, Effe2 and others.

- Basalt wool URSA - originally made in Italy. Today the company has 14 large production centers located in Europe, the Middle East and Asia, which, as a result, could not but affect the quality of the products. The URSA company specializes in the insulation of industrial and domestic premises, and is popular due to the good price-quality ratio of its products.

- Izovat basalt wool is a heater made in the near abroad, in Ukraine. The product range includes mineral slabs with a density of 30 to 200 kg / m³. It is worth paying attention to a brand intended for insulating brick chimney ducts with subsequent plastering of the surface. The thickness of Izovat boards is from 30 to 200 mm.

- Paroc basalt wool is a Swedish company specializing in the production of stone wool since the 30s of the last century. Paroc production workshops are located exclusively in the EU countries, which allows maintaining a high level of quality and full compliance with safety standards in force in Europe. Paroc basalt cylinders can be used to insulate iron chimney pipes. To this end, the company has developed the Paroc Pro Section and Paroc Pro Bend + Topcoat series, which provide maximum thermal insulation and protection for steel structures.

When choosing basalt for pipe insulation, it is mainly necessary to focus on the heat engineering characteristics specified by the manufacturer. On the basis of large concerns, modifications have been developed specifically for smoke extraction systems.