Thermal insulation and vapor barrier with Izolon PPE walls

Thermal insulation and vapor barrier Izolon PPE of frame, wooden walls made of timber and logs and brick walls of country houses and summer cottages

Recommended grades: Izolon PPE 3004 - 3015 Izolon PPE НР3004 - 3015 Izolon PPE НХ3004 - 3015

During the construction of frame buildings, a frame structure is mounted from rails with a pitch of 0.6 m. The space inside the wall frame is filled with heat insulator plates, it is possible to use Izolon or Izolon blocks. To protect the heat insulator from vapor saturation from the inside, Izolon PPE HP is mounted behind the inner lining. The thicker Izolon is used, the higher the effect of heat and sound insulation is.

Houses made of timber and logs, during the operation of the house, are often additionally insulated. Izolon is installed to protect the wall from heat escaping outside the insulation. When building a log and log house between the crowns, you can use Izolon PPE tape as a sealant.

In brick houses, houses made of aerated concrete blocks, expanded clay concrete, aerated concrete and cinder blocks, it is possible to additionally insulate the walls with Izolon PPE. Thus, the heat-shielding functions of the walls are increased. The thicker Izolon is used, the higher the effect of heat and sound insulation is. The minimum recommended application is Izolon PPE and whether PPE НХ3015 (15mm thick).

Sound insulation and thermal insulation with Izolon wooden frame internal walls and frame and frame sheathing partitions

Recommended grades: Izolon PPE 3005 - 3015 Izolon PPE НР3004 - 3015 Izolon PPE НХ3004 - 3015

During the construction of frame buildings, a rack frame is mounted with a pitch of 0.6 m. The space inside the frame is filled with heat insulator plates, it is possible to use Izolon blocks, Izolon PPE, PPE NH. To protect the heat insulator from vapor saturation from the inside, Izolon is mounted behind the inner lining. The greater the thickness of Izolon PPE, the greater the effect of thermal insulation and sound insulation.

As internal partitions, when zoning a house, structures of frame and frame-sheathing partitions are traditionally used. Izolon is used as soundproofing of partitions. It is recommended to lay the metal elements of the partitions with Izolon or Izolontape tapes to improve vibration isolation and sound insulation.

Sound insulation of walls with Izolon PPE is additional.

Recommended grades: Izolon PPE 3004 - 3050 Izolon PPE НР3004 - 3050 Izolon PPE НХ3004 - 3050

When, in order to increase comfort, additional sound insulation is needed in the rooms, which protects against street and internal noises that propagate through the building structures of the structure, it is recommended to soundproof the walls with Izolon. It is recommended to lay metal structural elements with Izolon or Izolontape tapes to improve vibration and noise insulation.

Heat-reflecting screen made of reflective insulation of Izolon foil behind the heating elements.

Recommendations: Foiled Izolon PPE 3004, 3005, 3008,3010

Foil Izolon sheet is mounted directly on the wall behind the heating element (convector, heating radiator) as reflective insulation. Between foil Izolon and the heating element, a gap of 1-2 cm is recommended. Foil-clad isolon, installed in a similar way, reflects heat into the room without heating the wall and, thus, increases the efficiency of the convector or heating radiator. The positive effect of heat saving and savings in heating costs are especially noticeable in cottages and country houses with autonomous heating.

Types and characteristics of insulation Izolon

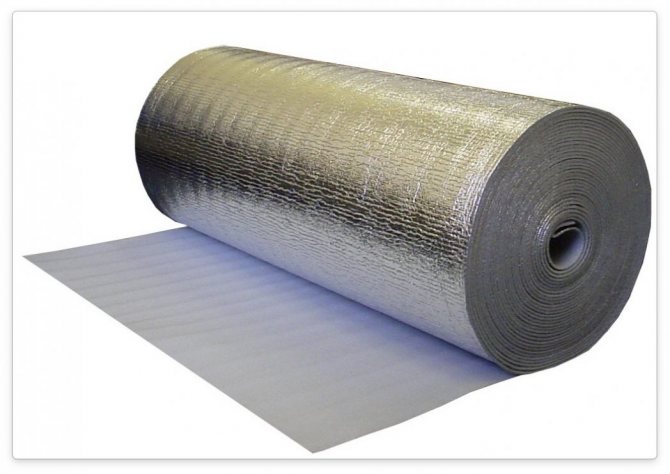

Foamed polyethylene Izolon with and without foil.

Izolon is a brand that produces polymer materials for insulation, noise and sound insulation with a closed-cell structure. Product line:

- Isolon 100 - uncrosslinked polyethylene foam;

- Isolon 300 - chemically cross-linked polyethylene foam;

- Isolon 500 - physically crosslinked polyolefin foam;

- adhesive tapes;

- reflective insulation - foamed polyethylene foam or metallized lavsan film.

The scope of the material is very wide: from civil engineering to production. This is facilitated by high performance. Insulation Izolon, characteristics:

- density from 25 to 100 kg / m. cube;

- thermal conductivity - 0.037 W / m * C;

- does not allow steam and water to pass through;

- foil materials emit 97% of IR radiation.

Some positions can withstand heating up to 100 degrees without changing their physical and chemical properties. The service life declared by the manufacturer is at least 30 years. All types of polyethylene foam absorb sound and vibration waves well.

The choice of insulation for the ventilation facade depends only on the material from which the walls are built. For wood, materials are used that allow steam to pass through, for concrete everything is suitable.

You can find information on insulating hives with polystyrene foam here.

What kind of foil vapor barrier is used in the bath?

Good afternoon, blog readers and all lovers to take a steam bath!

Today I propose to talk about the service of the latest modern technologies to increase the mood from visiting the steam room. Let's get straight to the point.

Foil vapor barrier for a bath has a lot of useful unique qualities. In particular, this is the ability to create a "thermos effect", which allows you to quickly warm up the room, while saving on fuel.

Agree that everyone prefers an individual thermal regime in their steam room - someone is constantly drawn to "put" the water on the stones, and someone likes a more moderate atmosphere. To ensure the comfort of all visitors, the choice of the optimal vapor barrier is required.

In this article, you will learn:

Isolon features and benefits

The material has the following properties:

- High reflectivity. Thanks to this, heat loss in the room is significantly reduced.

- Moisture proof. The insulation does not absorb moisture at all, which ensures its long-term operation without losing its heat-insulating properties. This characteristic is especially important when laying in wooden houses.

- Has a small thickness - from 2 to 15 mm, does not bear additional load on the structural elements of the frame. Excellent for floor insulation in rooms with low ceilings, saving usable room area. Despite its small thickness, its thermal insulation qualities are comparable to those of a brick wall.

- Environmental Safety. The material does not contain and does not emit harmful components, due to which it is completely harmless to humans, and it can be used in any premises.

- It has a long service life, retains its properties at temperatures from -80 to +120 degrees.

- Resistant to biological factors, not subject to decomposition and decay.

- Possesses good sound insulating characteristics.

The material is produced in the form of rolls or sheets of standard sizes.

For those who are interested in whether it is possible to insulate the floor with isolon, you need to give an unambiguous answer: "Yes", since the material goes well with wood and is the best choice for floor insulation in houses made of logs and beams. Izolon is also great for insulating ceilings, walls and other structural elements from inside the house.

The advantages of modern materials over traditional

In the bath, especially in the steam room, due to the extremely high humidity and temperature in the room, structures are strongly exposed to the aggressive effects of these factors, which significantly increases the risk of their premature destruction. To protect the walls and ceiling from wear and tear due to excess moisture and steam, it is necessary to install layers that protect the insulation in them from the penetration of water vapor.

Everyone, probably, had to go to the baths, where for this purpose cardboard impregnated with linseed oil, roofing felt or roofing felt with a layer of clay on top and filing with boards was used in the old fashioned way. Not only does these materials begin to give off an unpleasant odor when the air warms up well, but these fumes are also harmful to health.

A vapor barrier with foil is devoid of this drawback - it is completely safe for people. Due to the presence of a reflective coating, the use of such materials reduces the energy consumption for heating the steam room by 25-30%. Accordingly, it allows using less powerful electric heaters or saving solid fuel. In parallel, a "thermos effect" is created in the room, which prevents rapid cooling. The reason for this is that the foil vapor barrier is capable of reflecting back up to 98% of the radiant heat.

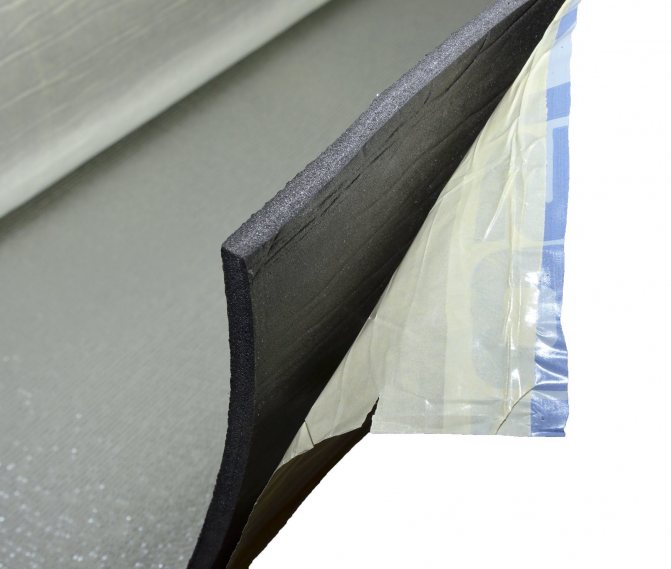

It is a composite material that consists of a backing made of foamed polymer and a reflective foil coating. Due to its water resistance, the occurrence of mold and all kinds of fungi is not threatened. The technical characteristics of the reflective foil vapor barrier enable it to effectively perform also the functions of insulation and reliable waterproofing. The material is able to withstand, on average, temperature drops from -40 ° C to + 100 ° C, which is important for saunas and baths.

Which side to attach the foamed polyethylene with foil

When the question arises of how to fix the foil insulation to the wall, then most often we are talking about penofol. This is an insulation that consists of two layers. The first layer is polyethylene foam and the second layer is foil. In addition, there are products in which the foil is on both sides. The reflective surface can be glossy, like a mirror, or wrinkled (embossed). It is believed that the relief allows you to slightly increase the reflection area, but not critical, so there is not much difference.

Unlike mats for floor insulation, regarding penofol, the answer to the question: "Which side to fasten the insulation with foil?" sounds like this: the base (foamed polyethylene) to the wall or other insulation.

The thing is that this material is used for both internal and external insulation. It turns out that during the thermal insulation of the facade, it will not work to put the penofol with the shiny side inward, it will look outward. What will it give us:

- such insulation will not reflect heat from the room, since there is no ventilation gap between the foil and polyethylene;

- the insulation will not let the summer heat into the house.

Two-layer reflective insulation, where polyethylene foam acts as a damper and reinforcement.

It is because of the absence of any significant displacements in the direction of increasing the thermal insulation qualities of the room that experts do not use penofol for external insulation. How to properly lay foil insulation penofol:

- you need to put it from the inside of the room with the shiny side to the heat source;

- there must be an air buffer zone (ventilated gap) between the foil and the trim;

- the material is laid end-to-end;

- fastened with either studs or staples;

- the joints are glued with aluminum (not ordinary, namely aluminum) tape.

Application of foil vapor barrier

If you decide to use such material in the construction of a bathhouse at your summer cottage, this does not mean at all that you need to incur significant costs. You don't need to invest a lot of money to insulate the entire building. The optimal solution is installation exclusively in the steam room and shower room. The foil layer effectively accumulates heat, the polymer inside reliably protects the structures from moisture and steam. For other premises, you can simply purchase material that is simpler and cheaper.

In addition to insulating walls, foil-clad material must be installed on the ceiling, under which hot air and steam are collected in the steam room. It is advisable not to forget to use it on the doors as well. But it is not worth laying any foil insulation on the floor, since its structure here usually consists of a concrete screed with a wooden flooring on top. The exceptions here are warm water floors.

Material description

Isolon thermal insulation consists of artificially foamed polyethylene, which looks like small cells or pores. Increased thermal insulation characteristics are achieved due to the porous structure. Using it, various surfaces and entire structures are insulated and waterproofed. The finished material can be in the form of a sheet, tape, block or roll.

The main area of application is hydro, sound and heat insulation. It is also used in household tasks, as it has better characteristics in comparison with similar products. The special structure makes Isolon a durable and wear-resistant material.

It is often used in tandem with other insulators. For example, if the task is to insulate the surface, it is combined with foam or expanded polystyrene. This "pie" allows you to qualitatively insulate walls, interfloor floors and loggias. It also serves as an insulating cover for the floor screed. It is also used in the production of cars - they insulate bodies with it, protect metal parts from corrosion.

Composition and specifications

To make an isolon, polyethylene is foamed, which explains its structure - air pores closed in a synthetic "body". Despite its elasticity, the material turns out to be quite soft, therefore it is convenient when working with geometrically complex surfaces. When making izolon, a thin foil layer of aluminum is made, the task of which is to reflect heat back into the room. As a result, it is possible to reduce the thickness of the insulation layer itself (the usual thickness for other products is 50-100 mm). The initial thickness of the isolon is 2 mm, but it is increased to 100 mm if necessary. It all depends on the area in which it is used. For example, to insulate a balcony, you will need insulation with a thickness of 20-30 mm.

Depending on the production method, there are two types of isolon: NPE and PPE (non-cross-linked foam polyethylene and cross-linked). They will be discussed in more detail later, and the technical characteristics of both options are in the table below.

| Index | PPE | IPE |

| Density | 33 kg / m3 | 24 - 45 kg / m3 |

| Operating temperature range | -60 to +75 degrees | -80 to +80 degrees |

| Thermal conductivity | 66 W / mK | 0.040 W / mK |

| Water absorption | 0,01 | 0,01 |

| Vapor permeability | 0.001 mg / (m * h * Pa) | 0.001 mg / (m * h * Pa) |

| Sound absorption | About 60% at 6000 Hz | from 3 to 13% |

Selection of material for insulation

The modern construction market offers a fairly wide range of such materials. But how to make the right choice for your bath? Since they are all fairly new, you can get confused about their differences.

By the way, please pay attention to the following point: the polymers that are part of the substrate can have different structures. Namely, they can be composed of polypropylene foam and polyethylene foam. We will not go into details, but the first option is suitable for high temperatures, the second is relevant for less aggressive environments.

Here are some technical specifications that will hopefully help you choose the right one from the most popular materials today.

- Penotherm differs in a base made of expanded polypropylene and a large operating temperature range - from -40 ° С to + 150 ° С. The certificates confirm its moderate flammability, low-hazard class of toxicity. There is virtually no thermal shrinkage during operation. The NPPLE model can be used for the installation of underfloor heating. Great for a steam room.

- IzospanFB designed directly for creating a vapor barrier in baths and saunas.It can be safely used at high temperatures. You can read more about the many markings and uses of isospan in this article.

- Alufhas a polyethylene foam base and one-sided aluminum foil coating. The temperature range is in the range from -60 ° С to + 100 ° С. In addition to the functions of hydro, sound, steam and heat insulation, it includes protection against radon. It can be used for insulation of floors and roofs. The special "wrinkled" surface texture makes it possible to bend around curved elements of small radii during installation without breaking the foil coating.

- Tepofol has a polyethylene foam base, can have a reflective layer on one or both sides in different models. Withstands temperature influences from -60 ° С to + 100 ° С. It can be used for thermal insulation of roofs, walls, air ducts, warm floors. Supplied to the market in various variations.

- Izolon environmentally friendly and safe material. The base is also foamed polyethylene foam. It is a durable, vapor-tight, soft and flexible foil insulator.

Application of non-crosslinked material

To obtain the best result, isolon NPE is placed on a surface free of dust and large debris.

Such insulation also has good properties and characteristics. It is a non-toxic material, which is why it is often used as packaging. This versatile product is capable of absorbing mechanical and shock loads. Izolon NPE was able to squeeze out air-bubble wrap and even corrugated cardboard, gaining immense popularity.

Uncrosslinked polyethylene can burst on contact with a sharp object or point load. But this does not limit its use. Izolon packaging is suitable for storing household, electronic and computer equipment, glass items, dishes, furniture and other products. It is convenient to use IPE during transportation as a wrapping material or a pad.

Izolon is not afraid of severe frosts, this allows you to use insulation at temperatures from -40 to + 90 ° С

In the engineering industry, when performing construction and repair work, the use of isolon is limited. But if there are no large bearing loads and high temperatures, then it is laid as thermal insulation, protection against condensation, steam and noise. Also, substrates are made of the material for leveling the floor covering before laying parquet or laminate. Foamed polyethylene foam is used as reflective insulation to reduce energy costs.

Installation of foil vapor barrier

The installation of this insulation is so elementary that its implementation on your own can not cause you any difficulties:

- The material is attached longitudinally to the ceiling in the bath and vertically to the walls, and the panels should partially extend onto the floor;

- For the effective operation of the material between it and the supporting structure, it is necessary to leave a gap of at least 15 mm., Also, a gap is required between the foil and the finishing (clapboard);

- The sheets must be overlapped so that the foil side is oriented towards the inside of the room;

- Fastening is done with nails or a stapler, while it is necessary to lay it carefully, avoiding damage to the insulation - otherwise it will partially lose its functions;

- The seams must be glued with metallized tape, by the way, a very good thing;

- Using self-tapping screws (for wooden walls) or dowels (for brick structures), lathing bars are attached;

- Vertical or horizontal decorative cladding is performed, and the lining should be made of aspen or linden (relevant for a steam room).

With this, with the wish to get the maximum pleasure from going to the bathhouse, I say goodbye to you. If you have friends interested in arranging and insulating a bath, share this information with them on social networks.In subsequent articles, there will be many more useful and interesting things. And by subscribing to the blog update, you will always be promptly informed about new publications. Light steam!

Quote of wisdom: Only completely strangers are told about the most intimate.

Complex insulation of a balcony with Izolon

In the photo, the balcony is ready for finishing.

Insulation of the balcony with Izolon, like the loggia, should be carried out in a comprehensive manner. This means that the insulation must be fixed everywhere: on the floor, ceiling and walls. Keep in mind that no insulation will help without good, energy-efficient windows. The lion's share of the heat goes through the glass (if everything is hermetically sealed). We have already written about how to check heat loss. High-quality insulation of the balcony with only one Izolon is nonsense, thick thermal insulation materials are needed. The best option is polystyrene with a density of 25 kg / m. cub.

We present to your attention the fastest and easiest way to comprehensively insulate a balcony:

- foam is glued to the walls and ceiling with glue-foam;

- guides are laid on the floor along the level;

- between the guides, you can simply put the foam in two layers with a gap in the joints, all the cracks are foamed with the same glue-foam;

- the entire balcony is tightened with a shiny side foiled with insulation in the middle of the room, the joints are glued;

- logs are placed on the floor guides, and everything is sewn up with an OSB plate - the floor is ready;

- wooden bars are drilled into the walls and ceiling through polystyrene - this is a crate;

- finishing is attached on top of the lathing.

This method minimizes the use of a hammer drill, and there is no need to dilute all-purpose building glue. It saves time and nerves, and the result is excellent. Everything will hold on securely and never fall off, you won't even be able to tear it off on purpose.

Now let's summarize our today's article about Izolon. Insulation for floors, walls and ceilings without foiling works more as sound insulation, protection from steam and moisture. It is often used as a lining under laminate or even linoleum. The thermal insulation qualities of foamed polyethylene are quite high (0.037 W / m * C), but with a small thickness, the effect is insignificant. Foil materials emit infrared rays, which is very useful, especially in a bath. A gap of 15 mm or more must be maintained between the foil and the trim.

The floor is the lowest part of the house, which is in close proximity to the ground. Usually, heat escapes from the room through it, and cold and dampness penetrate inside. If you do not want to live in a cold and uncomfortable house, then the floor must be insulated. Isolon occupies one of the leading places in the modern construction market. This material has been used as insulation for many years and in fact has shown its excellent thermal insulation properties. In the article, we will describe in detail the characteristics and advantages of the material, and also dwell on how to insulate the floor with isolon in a wooden house, and highlight the subtleties of this work.

Structure and specifications

Izolon is an elastic soft synthetic material made by foaming polyethylene. It consists of the smallest closed cells (pores). Most often, it is supplemented with a thin layer of aluminum foil (foil isolon). The material is sold in the form of sheets, tapes, blocks and rolls.

Main technical parameters:

- thickness - 2-100 mm;

- sound absorption - up to 68%;

- density - 19-200 kg / m 3;

- water absorption - up to 1%;

- heat reflection level - 95-97%;

- permissible operating temperature - from -80 to +80 ° С.

As follows from the characteristics, foil-clad isolon insulation has excellent heat, sound and moisture insulating properties. The exact figures depend on the type of material.

Isolone varieties

The quality of a sewn isolon is higher than that of an uncrosslinked one, since the crosslinking provides a higher heat resistance of the material

This material is of 2 types: cross-linked (PPE) and non-cross-linked (PSE). The first option has a structure similar to polyethylene, which does not change even during heat treatment. Such products do not pose a danger to humans and the environment. Cross-linked polyethylene foam has a slight specific odorwhich disappears after 2-3 weeks.

Read the same: properties and characteristics of insulation Izolon PPE.

Uncrosslinked isolon has an unbound molecular structure, so the product is more resistant to aggressive media and more durable. Plus, it doesn't require much maintenance.

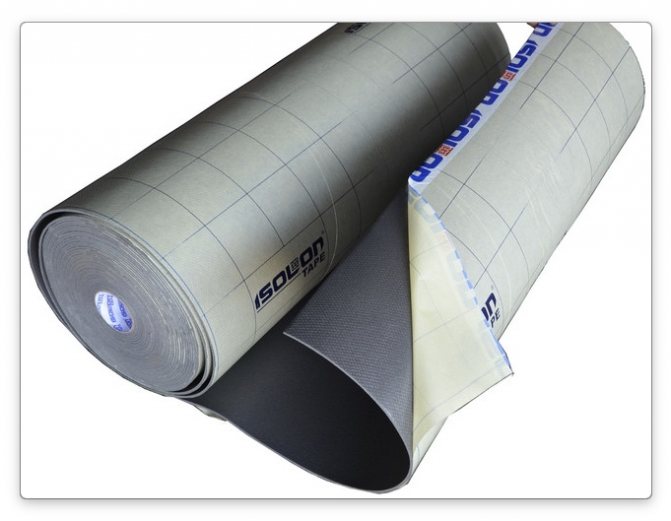

The difference between these materials is determined, as a rule, by their resistance to dynamic impacts and their ultimate strength. Moreover, the first indicators of the PPE are significantly higher than that of the IPE. Isolon is marked as follows:

- A - the product is covered with aluminum foil on one side;

- C - material with an adhesive layer;

- B - products with double-sided foil;

- ALP is a foil-reinforced self-adhesive sheet covered with a protective film.

These characteristics will help you to choose the right thermal insulation material without any problems, focusing on individual preferences and field of application.

We bring to your attention a video, which shows in detail how to properly and independently insulate a balcony with isolon material:

Areas of use

The main areas of application of isolon are construction and repair of buildings, as well as the automotive industry. Often it is combined with other heat-insulating materials - expanded polystyrene (polystyrene, expanded polystyrene, etc.).

Use in construction and repair:

- insulation and sound insulation of walls, roofs, floors, floors, foundations in residential, utility and industrial premises - in private houses, apartments, basements, garages, on balconies, loggias, in workshops, warehouses, offices, gyms;

An example of using foil insulation on a balcony

- heat and vapor insulation of rooms with high air humidity - baths, saunas;

- insulation of pipelines;

- the creation of a self-leveling floor - a layer of thin isolon, laid on the screed, protects against leaks of the composition to the lower floor, and also serves for thermal protection.

- insulation of the inner surface of the body (floor, hatch doors) in order to reduce noise and vibration levels, as well as to retain heat;

- protection of metal parts of the car from corrosion.

Isolon application in the automotive industry:

Found izolon foil-clad application in other areas, including:

- the medical industry - packaging of fragile equipment, the manufacture of orthopedic insoles, shoe inserts, thermal blankets and the like;

- production of refrigeration, heating and climatic equipment;

- production of workwear - suits for sports, life jackets and so on.

Good result

Reliable insulation of the walls with the above-mentioned building element is carried out thanks to the air cushion, which further helps to reflect the heat. Also, a high-quality result can be achieved by means of an isolon foiled on both sides. Such material is able to withstand up to 120 degrees. Celsius!

RECOMMENDED TO READ

- 20.01.2015Bimetallic radiators - heating without flaws

- 08.01.2015All about gas boilers

- Quality and guarantees, how to get everything at once

- 10/02/2014 Do-it-yourself buleryan bake

Production stages

Isolone production process is divided into three main stages:

- Mixing. One container combines polyethylene in granules, a foaming agent and "crosslinking" agents, that is, substances that irreversibly transform polymer molecules.

- Extrusion. The polymer mass is heated and melted. In parallel with this, future isolon sheets are being formed.

- Foaming. The sheets are sent to the oven on a conveyor net. Under the influence of high temperature, the foaming agent is activated, and many pores are formed in the structure of the material.

In the production of foil-clad isolon, at the last stage, a thin aluminum foil is glued to the foamed polyethylene layer by lamination.

Advantages and disadvantages

Isolon insulation has many advantages, which makes it so popular:

- safe, does not have a harmful effect on human health;

- due to low water absorption and vapor permeability, the insulation can be used without a waterproofing layer;

- elastic, therefore easy to lay in difficult places. At the same time, it is elastic, therefore it easily takes its original shape after dismantling and can be reused;

- precipitation and ultraviolet light are not terrible for isolon, therefore it is suitable for outdoor work;

- Isolon is one of the best wall insulation materials. Example: 10 mm of insulation = 15 cm of brickwork, 20 mm of mineral wool or 5 cm of wood. Heating costs are reduced by almost three times;

- does not put a load on the processed structures, since it weighs little;

- fireproof;

- service life reaches 80 years;

- during manufacturing, the material is not only covered with foil or metallized film, but also embossed and painted;

- isolon is easy to use. It is easy to cut and attach to the surface, allowing for a self-adhesive base. Also, a stapler, small nails, self-tapping screws or silicone glue can be used for fixing;

- waste raw materials are reused;

- aggressive chemicals and biological destructors do not affect the material;

- wide choice in terms of dimensions, density, thickness.

Dignity

The main advantages of foil-clad isolon:

- high dynamic strength, resistance to mechanical stress;

- durability - service life 80-90 years;

- immunity to various chemicals - gasoline, oil, oil, fuel oil and so on;

- resistance to ultraviolet radiation and atmospheric precipitation - isolon can be used for outdoor insulation work;

- fire safety - the material does not burn, under the influence of fire it decomposes into carbon dioxide and water;

- light weight - izolon does not create additional load on the elements of a building or car;

- elasticity - foamed polyethylene can be pasted over any structure, it will take its shape;

- elasticity - the material restores its original appearance well after the cessation of mechanical action, it can be reused;

- high level of heat and sound insulation;

- very low tendency to absorb moisture and steam;

- resistance to the decay process;

- ease of installation - the sheets are attached to the surface using a self-adhesive base, and if it is not there, then you can use silicone glue, furniture stapler or self-tapping screws;

- ecological cleanliness and safety for human health - isolon does not emit toxic substances.

Approximate savings on heating when using Isolon for thermal insulation of a dwelling is 30%.

Insulation of the floor with isolon

Summing up

So, we found out that there are several types of foiled insulation:

- polystyrene in sheets for the floor;

- mineral wool in sheets and rolls;

- penofol;

- shells for insulation of pipes made of foam and mineral wool.

All types of insulation, except for shells, with a reflective layer are intended for internal insulation. Foil should be placed in the middle of the room. For outdoor insulation, such materials are suitable, since the concept of reflecting infrared radiation is nullified. Therefore, it makes no sense to pay for something that does not bring results.

It is necessary to glue foam and mineral wool slabs on a special plaster-adhesive mixture from trusted manufacturers. The latter include the same Knauf or Ceresit.Laying on the walls is carried out from the bottom up, the sheets are additionally fastened with dowels. And most importantly, there is a ventilated gap in front of the reflective surface. If it is not there, then instead of reflecting heat, you will get even more heat leakage, plus mold on the decoration.

The materials used in the construction of roofs and the arrangement of premises with non-standard temperature and humidity operating conditions are endowed by manufacturers with special properties. They not only freely resist the attacks of hot air saturated with steam, but also create a "thermos" effect, due to which the energy consumption for heating is significantly reduced.

These specific products include foil vapor barrier, the installation of which allows you to solve a lot of important problems in the construction of building structures.

Disadvantages and application features

The list of disadvantages of foil isolon is much shorter than the list of advantages. Main disadvantages:

- relatively high price;

- the need for careful transportation and careful installation (it is important not to damage the aluminum layer);

- Izolon can only be painted or covered with a protective film, you cannot glue wallpaper and apply plaster - any finishing materials "load" the insulation with their weight, increasing the risk of breaking it.

When using isolon, it is very important to follow certain rules so that the material does not lose its characteristics:

- insulation sheets should be laid end-to-end, using aluminum tape to seal the seams;

- when insulating surfaces, it is imperative to leave ventilation gaps between the isolon and other elements, otherwise condensation will form, and the materials will begin to collapse;

- foil-clad isolon should not be laid near electrical wiring, since aluminum conducts current.

Foil isolon is an innovative material used for noise, heat and moisture insulation in everyday life and industry. It perfectly fulfills all its functions, even if the thickness is insignificant. With proper installation, izolon can last up to 90 years. The material fully complies with modern quality standards in terms of fire and environmental safety.

Laying heat-insulating material

The optimal indicator of insulation is achieved when an air cushion was provided between the wall and the insulation, the total thickness of which should not be less than 15-20 mm. To do this, it is recommended to fix a special lattice of slats on the wall surface, the thickness of which should not exceed 15-20 mm. The lattice cells are staggered at a distance of about 1 m from one another. The size of the lath should be made equal to 1-1.5 m. Fixation is carried out using a stapler or small nails. It should be recalled that the edges of the heat-retaining material must be carefully joined together using aluminum tape. After that, a lattice of slats is again nailed to the base of the isolon, it is on them that the finishing materials will be attached in the future.

Isolon fixing technology to the wall and material variations

The modern construction market is replete with all kinds of novelties, often these are universal materials for a wide range of applications. We will talk about one of these materials today. This miracle of engineering, called Izolon, is widely used in construction as a heat and sound insulating material. We will describe in more detail all of its capabilities later. First, let's focus on the main value - wall and floor insulation. Fastening the isolon to the wall is a very straightforward process, and to the floor, in general, it's as easy as shelling pears. The principle of fastening is similar to other soft-type insulation - they are attached to the wall by means of a crate, which also serves as a frame for future wall decoration, for example, plastic panels.

There are technologies for using isolon both indoors and outdoors. The second option is more practical (cold air is cut off, the walls do not freeze, and the heat from the inside of the house does not go anywhere), but it is also more financially costly, since the walls are insulated with isolon from the outside mainly for siding. How to insulate - from the inside or outside - it's up to you, but we'll try to tell you in more detail about the mzolon itself, the spectrum of its application, technical characteristics and other interesting facts.

Secret. How to glue foil insulation to the wall.

Kind. Somehow I ran into a problem to glue the foil insulation to the wall. There is a lot of information on this in the Internet. But how and with what glue I did not try - in the end, nothing happened. Everything fell off. And the secret is simple. The insulation is covered with a thin plastic film, to which the glue does not stick (to a smooth surface, it has nothing to catch on) The manufacturer did not take this into account, or did not want to. It is enough to make the places where the glue is applied, rough, that is, sand it with sandpaper. You can use any glue, as well as polyurethane foam. And you won't need a stapler, nails, dowels, military strategic poisonous fluids - as mentioned in many construction forums. Good luck to everyone, go for it.

Small observation. But many do not see the little things. Hence the big problems.

It is enough to make the places where the glue is applied, rough, that is, sand it with sandpaper.

And most importantly - why spend money on this and other materials and glue something that will not bring any effect.

jekasus wrote: And most importantly - why spend money on this and other materials and glue something that will not bring any effect.

Apparently the vehicle just has material for free and time must be killed.

jekasus wrote: And most importantly - why spend money on this and other materials and glue something that will not bring any effect.

Yes, I agree with you. But this effect is not in the preservation of heat, it is enough, water heating comes from the house. If you take a closer look at the last photo - this is an extension of the future greenhouse from the north side, of course there will not be enough light for the plants. Reflective paint is out of stock. So the foil serves to reflect it. Even with artificial lighting, when entering the room at night it is not possible to look, the eyes are cut by a bright, dazzling, iridescent light. (Checked, a few light bulbs are enough) That's a plus for energy saving. In general, the issue was not considered on the construction of greenhouses and where, why should the foil insulation be glued. The meaning of how to glue!

How to fix isolon to the wall

Kind. Somehow I ran into a problem ** to glue ** foil insulation to the wall. In the ** Internet ** there is a lot of information about this. But how and with what glue I have not tried - in ... - photo- Forum Mastergrad

What is Isolon?

Izolon is a universal insulating agent made of flexible polyethylene foam that provides all types of insulation. The widest assortment of isolon is presented in:

- Material treated with an electric discharge and can be wetted with adhesives and paints.

- Foil laminated rolls.

- Rigid and heat resistant sheets.

- Multi-colored.

- With a reduced level of flammability.

All of these are various subspecies of amazing material, but they all have:

- The unique heat-insulating property of a thin material (1 cm), which can be replaced with 5 centimeters of wood or mineral wool, 150 millimeters of brickwork, 12 millimeters of expanded polystyrene.

- Effective protection against steam and moisture due to the closed cell structure. Water is not absorbed by the material.

- Excellent sound and shock insulation.

- Softness, elasticity, light weight (except for hard tile samples).

- Durability, resistance to decay, low level of flammability, which provides it with a warranty period of up to 90 years

- Chemical stability that allows it to be combined with all known materials.

- Environmental safety, since the material does not have a strong odor, does not emit toxins either when heated or at rest. The materials from which the isolon is made do not harm nature, even contact with food is allowed, so the insulation of the walls with the isolon inside is completely safe.

- Versatility and ease of installation. This material is excellent for floors, walls, both inside and outside, roofs in residential and commercial premises. Installation can be carried out by anyone, even without construction skills.

Views

The following types are available:

- unstitched - NPE;

- cross-linked - PPE, which is divided into subspecies: chemically cross-linked PPE NKh and physically cross-linked PPE NR.

According to its characteristics, the NPE isolon is inferior to the sewn one.

Izolon PPE is resistant to aggressive effects and has higher values of heat, sound and moisture insulation. It is possible to combine different types in one product.

To reduce losses from radiation of heat waves absorbed by the internal surfaces of the room, a rather simple, but very effective method is used - covering the isolon with foil. The role of the foil is its ability to reflect infrared rays. This significantly increases the importance of isolon in its fight against heat loss.

Please note: Mineral wool characteristics and properties

Foil isolon can be of the following modifications:

- "A" - one-sided foil covering;

- "B" - covered on both sides at once, which increases resistance to external influences;

- "C" - self-adhesive;

- "ALP" - self-adhesive, with a protective film.

Insulation with foil must be laid in such a way that its metallized layer "looks" into the room to be insulated. When laying foil-clad isolon with a protective film, it should be carefully removed, freeing the surface with the applied adhesive. If a non-self-adhesive version is used, then glue should be used, which, in terms of its qualities, is suitable for this purpose. Some varieties of Isolon have a high wettability value, which makes it easier to use glue for fixing them.

Information. Foil isolon increases the heat-reflecting properties of the surface up to 98%!

How to apply?

Isolon's scope of application goes far beyond the boundaries of the construction field: it is actively used in the production of cars, refrigeration equipment, the medical industry, in plumbing, and even in the oil industry. He also found his application in the production of life jackets, sports equipment, packaging.

Most often, Izolon is used for installing a warm floor and insulating loggias and balconies. There are technologies that allow the use of Isolon in the insulation of external and internal walls, roofs, but the principle, as they say, is one. The only difference is that in cold, unheated rooms, which include the balcony, one isolon is not enough, then the technology of a sandwich made of cotton wool insulation or expanded polystyrene and foil-clad isolon is used. If the room is small and you cannot give additional space for insulation, then you should increase the thickness of the isolon to at least 2 centimeters. Using the example of insulating a loggia, we will show the principle by which you can insulate (with certain deviations depending on your conditions) any surface.

How to properly attach an isolon is still known to very few, since the technology is quite new. Isolon on the walls is laid with foil inside to reflect heat.If you prefer a sandwich, then a gasket is made of mineral or glass wool, foam plastic, expanded polystyrene between the two layers of isolon, a crate is mounted on top for decorative materials such as plastic panels, lining, etc. All seams are carefully glued with a special reflective tape, tightness during the insulation process is very important, so this advice should not be neglected.

In order to more clearly describe all the processes, a short step-by-step instruction is provided:

- Clean and dry the surface to be attached.

- Measure the area, prepare the required amount of material.

- Unfold, attach the isolon to the surface with foil towards you.

- Glue all existing seams and attachment points with special tape.

The manufacturer gives several more ways to use isolon:

- The use of sheets for concrete hardening - isolon prevents heat loss and rapid drying, therefore it is invaluable as a material for concrete masonry.

- Like artificial turf bedding.

- As dividing partitions when pouring the foundation.

- When isolating water supply, drainage, ventilation pipes.

- As heat-reflecting screens (fixing the isolon to the wall behind the battery allows you to redirect warm air masses inside the room, which prevents rapid cooling. According to statistics, energy savings in this case exceed 25%).

Features of the use of foil insulation

The use of materials with foil for insulation depends on a couple of indicators: the properties of a particular heat insulator and the place where it will be used. In general, with the help of such thermal insulation, floor structures are insulated, the heat transfer of heating radiators is increased, air ducts and pipelines are trimmed. An excellent result gives and thermal insulation of entrance doors to verandas, loggias, porches and balconies.

When installing foil-type insulation, you need to acquireall the necessary tools for work:

- Construction stapler.

- Small carnations with a large cap.

- Claw and hammer.

- Foil-coated construction tape.

- Insulation with foil directly.

The most common mistake of many builders is the incorrect installation of the material with the foil surface outward. Due to the fact that the foil is a reflector, it is designed to return heat to the room. And by placing the insulating material on the wrong side, such an effect cannot be achieved.

Stacking foil heat insulator, it is recommended to enclose it in a crate made of wood.

Boards, rolls or sheets of material must not be overlapped. They must be installed strictly on the same plane, secured with nails or construction staples.

The material that has an adhesive surface can be left without additional fasteners, but it is better to use small studs to increase the service life. In the absence of an adhesive coating, a rubber or acrylic adhesive can be used to fix the material to the surface.

After installation and fixing all layers heat insulator, the joints between them must be treated with foil tape. This completes the installation.

When installing the heat insulator on vertical surfaces on which there is mold, wallpaper or dirt, they must first be cleaned, otherwise the fixation will turn out to be very unreliable, and the material will simply fall off over time. In addition, it is recommended to treat the surface with antiseptic agents.

Alternative types of materials

There is no alternative to isolon, as such, but we would be wrong if we do not briefly talk about the materials that, in certain cases, can replace it.

Almost the same as Isolon, cotton wool materials, which include mineral, glass and ecowool, have heat and sound insulation. Their manufacturers insist that their main advantages are:

- Ease and simplicity in installation.

- Low thermal conductivity.

- Compressive strength, mechanical stress, rupture strength.

- High soundproofing characteristics.

- Not susceptible to fire.

- Resistant to thermal deformation.

- Biological and chemical resistance.

Mineral wool is produced in the form of rolls and sheets, they have different softness and thickness. It is extremely easy to mount structures using various types of wool:

- The walls must be closed with a steam or hydro-barrier using a stapler.

- The next step is the assembly of the frame from special metal profiles, the assembly step is 50 centimeters.

- Then cotton wool is laid, carefully distributed throughout the space, avoiding gaps.

- Then the cotton wool is fixed in any convenient way, the structure is closed with sheets of drywall, plastic panels, clapboard, fiberboard.

- The final stage is wall decoration, its type depends on what material you have chosen or is available.

The disadvantage of the material is its allergenicity; one should work in protective gloves and a mask to prevent contact of the material with the mucous membranes and skin of the hands. It also requires additional vapor barrier, since it loses its properties from moisture. In principle, the technology is simple and you can easily do everything yourself without overpaying to contractors.

Styrofoam or its analogs

The undoubted advantages of foam include the fact that:

- Polyfoam is not afraid of moisture.

- It is a good heat insulator.

- It is not subject to decay, the formation of fungal or mold stains.

- Easy to install and cut.

- It is lightweight.

- Heat resistant to low temperatures.

- Does not require waterproofing.

There are also many disadvantages of foam:

- It is fragile, crumbles, requires additional protection with a dense base.

- Doesn't breathe.

- Easily destroyed, enters into chemical reactions.

- Loved by rodents.

Polyfoam is used mainly in non-residential premises or for outdoor use. Installation is carried out on an adhesive mixture, it requires additional fixing with "fungi", careful coating of joints, plaster and subsequent painting.

Insulation of walls with isolon

Thermal insulation of walls is carried out according to the same options and according to the same principle as floor insulation.

So that the sheets of material do not fall and do not create discomfort in work, their laying is carried out according to the principle from the bottom up. For fastening mineral wool, on the rails are installed ceiling hangers

... They are sold in a hardware store and hold the mineral filler well. If desired, you can use special glue. The preliminary fastening of the isolon can be carried out using

construction stapler.

Note!

For finishing and decorative work, plywood sheets can be replaced with drywall sheets.